I will apologize now for the length of this post.

I have had a Power steering leak for quite some time, it was a slow leak so I just kept adding every couple of months. This past winter it turned into a big leak, I would top it off go for a drive and it would be low. OK I guess it’s time to fix it. I pull it in the garage and start looking. I topped off the fluid, started the vehicle, and turned the steering wheel a few times from stop to stop, could not see any leaks. I didn’t need it the next day so I left it in the garage jack stands. A couple of days later I went back and there was a wet spot under the driver side tie rod, I noticed that the boot was torn (according to posts found here the Rack is gone). It was wet but I could not see it leaking, I figured with how quickly the reservoir was draining I should be able to see something dripping while the vehicle was running and turning the steering wheel. So I kept looking, I noticed it was wet around the bottom of the rad, but could not see a leek. There is an 8” plate bolted to the frame on the right hand side where the lines come down from the pump and then run along the frame I took this off and got soaked with fluid. I turned the steering wheel again and could see a steady stream of fluid coming out of the pressure hose and hitting the rad.

OK so I have 2 problems:

- Rack – I found a very good write up https://gmtnation.com/forums/thread...-pinion-for-i6-ext-2006-4wd-trailblazer.2616/

- Pressure line – I found a couple of write up’s but still have some issues power steering hose replacement - Chevy TrailBlazer, TrailBlazer SS and GMC Envoy Forum

Using the write up for rack I was able to remove and replace the rack.

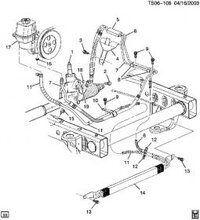

Using the picture on bottom of the post.

Now I move on to the lines. I figured while I’m there I may as well change the return lines also. To remove the bolts holding on #8 I had to remove the fender liner. To remove the bolt holding on #10 I had to use a long extention and a u-joint, not sure how I will get it back in (any ideas?).

Questions:

- How do I remove brackets #8 & 10 from the old lines and put them on the new lines. I thought of cutting them and getting new ones but when I called the dealer they had no information on those parts. They are not stocked in North America. If that is the case they must be easy to remove???

- After putting the rack in and torquing everything down I take a look at the mounting for the lines to the rack…how am I going to do that? It’s all hidden by the frame or the CV. Are there any tricks?

Thanks for taking the time to read this.

Jerry

I have had a Power steering leak for quite some time, it was a slow leak so I just kept adding every couple of months. This past winter it turned into a big leak, I would top it off go for a drive and it would be low. OK I guess it’s time to fix it. I pull it in the garage and start looking. I topped off the fluid, started the vehicle, and turned the steering wheel a few times from stop to stop, could not see any leaks. I didn’t need it the next day so I left it in the garage jack stands. A couple of days later I went back and there was a wet spot under the driver side tie rod, I noticed that the boot was torn (according to posts found here the Rack is gone). It was wet but I could not see it leaking, I figured with how quickly the reservoir was draining I should be able to see something dripping while the vehicle was running and turning the steering wheel. So I kept looking, I noticed it was wet around the bottom of the rad, but could not see a leek. There is an 8” plate bolted to the frame on the right hand side where the lines come down from the pump and then run along the frame I took this off and got soaked with fluid. I turned the steering wheel again and could see a steady stream of fluid coming out of the pressure hose and hitting the rad.

OK so I have 2 problems:

- Rack – I found a very good write up https://gmtnation.com/forums/thread...-pinion-for-i6-ext-2006-4wd-trailblazer.2616/

- Pressure line – I found a couple of write up’s but still have some issues power steering hose replacement - Chevy TrailBlazer, TrailBlazer SS and GMC Envoy Forum

Using the write up for rack I was able to remove and replace the rack.

Using the picture on bottom of the post.

Now I move on to the lines. I figured while I’m there I may as well change the return lines also. To remove the bolts holding on #8 I had to remove the fender liner. To remove the bolt holding on #10 I had to use a long extention and a u-joint, not sure how I will get it back in (any ideas?).

Questions:

- How do I remove brackets #8 & 10 from the old lines and put them on the new lines. I thought of cutting them and getting new ones but when I called the dealer they had no information on those parts. They are not stocked in North America. If that is the case they must be easy to remove???

- After putting the rack in and torquing everything down I take a look at the mounting for the lines to the rack…how am I going to do that? It’s all hidden by the frame or the CV. Are there any tricks?

- I have aftermarket lines so the pressure line comes with a separate plate to mount to the rack…

- Do I take out the driverside bolt holding the rack and loosen the passenger side and rotate the rack so I can get to the lines to put the mounting plate and lines together and start the bolt mounting the plate and lines to the rack? Would there be enough movement in the lines?

- Do I remove the CV I think that might give em enough room?

- Other thoughts?

Thanks for taking the time to read this.

Jerry

Attachments

Last edited by a moderator: