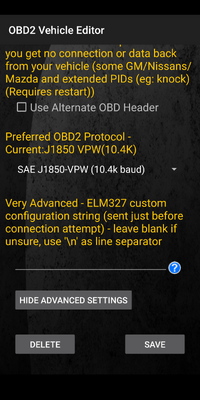

As far as inexpensive bluetooth adapters go I went through 3 of differing manufacture before settling on the following which was my 4th. I now own three of this unit which have proven themselves.

My first three from other manufacturers also gave me some issues with connectivity, dropping connections and such. I cannot say that it wasn't the fault of the app(s) I was using at that time. They usually maintained connection while using Torque Pro though.

I will add that all of these devices and apps like Torque Pro etc. simply cannot replicate the speed of data acquisition that a professional scantool like the Tech 2 can achieve. This is because they use differing data retrieval methods.

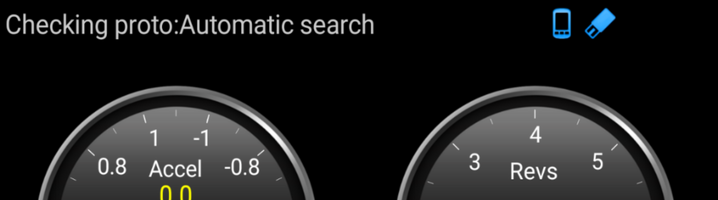

For every dial or graph or what have you that Torque Pro displays there is a query/response that must be sent and recieved sequentially. So if you have 6 data points displayed Torque will ask for the first then the second, then the third and so on. When it reaches the last one it starts back at the first. For each request Torque gets back one response. Then that data point has to wait until all the other data points have been requested and retrieved before it gets another time slice to update the data it got last. Additionally there are some data points Torque asks for that are not displayed, like engine RPM. And all along these messages have to merge in with the normal data traffic of the vehicle. And on top of this Torque sometimes has to alter the request format if it doesn't see a response to a given query. This whole procesure doesn't lend itself to things like graphing a fast changing parameter.

By contrast a Tech 2 knows how to instruct the PCM to create a data packet that can contain as many as 6 data points in a single response message and stream that packet so it doesn't need to be repeatedly asked for with yet another message. Far more efficient.

So when you see graphs from Torque that lack uniformity consider that the data points can be somewhat crude and you likely aren't seeing the peaks and valleys as they really exist. I see you have used the graphing selection from Torque and this is a good choice for viewing things like fuel trims and O2 sensor data. Keeping the overall number of data points displayed low is a good strategy as well. And avoid logging data in the background unless necessary because that adds to the workload.

My first three from other manufacturers also gave me some issues with connectivity, dropping connections and such. I cannot say that it wasn't the fault of the app(s) I was using at that time. They usually maintained connection while using Torque Pro though.

I will add that all of these devices and apps like Torque Pro etc. simply cannot replicate the speed of data acquisition that a professional scantool like the Tech 2 can achieve. This is because they use differing data retrieval methods.

For every dial or graph or what have you that Torque Pro displays there is a query/response that must be sent and recieved sequentially. So if you have 6 data points displayed Torque will ask for the first then the second, then the third and so on. When it reaches the last one it starts back at the first. For each request Torque gets back one response. Then that data point has to wait until all the other data points have been requested and retrieved before it gets another time slice to update the data it got last. Additionally there are some data points Torque asks for that are not displayed, like engine RPM. And all along these messages have to merge in with the normal data traffic of the vehicle. And on top of this Torque sometimes has to alter the request format if it doesn't see a response to a given query. This whole procesure doesn't lend itself to things like graphing a fast changing parameter.

By contrast a Tech 2 knows how to instruct the PCM to create a data packet that can contain as many as 6 data points in a single response message and stream that packet so it doesn't need to be repeatedly asked for with yet another message. Far more efficient.

So when you see graphs from Torque that lack uniformity consider that the data points can be somewhat crude and you likely aren't seeing the peaks and valleys as they really exist. I see you have used the graphing selection from Torque and this is a good choice for viewing things like fuel trims and O2 sensor data. Keeping the overall number of data points displayed low is a good strategy as well. And avoid logging data in the background unless necessary because that adds to the workload.