Hello Gentlemen,

I apologize ahead for opening this thread again I’m sure it has been discussed numerous times but I’m struggling to find the culprit regarding my P0171 code, I have 2004 Trailblazer LT and here’s what I have done so far:

-Vacuum leak checked with a smoke machine and none were found.

-SAIS was deleted and installed a block off plate.

-Replaced O2 upstream sensor.

-Replaced MAP Sensor.

-Tried to tight down intake manifold bolts to the best of my ability and I’ve managed to tighten most of them down however on there was one bolt towards the front of the engine (before the ECM mount) was almost rounded off it seems like someone was on it before (probably the previous owner) so i haven't ruled out the intake manifold yet.

-Cleaned TB and changed the gasket.

-Replaced fuel filter.

-Fuel pressure tested (My readings were 49PSI with key ON and 52PSI with car on idle) also did a leak down test for 10 minutes and no pressure drops.

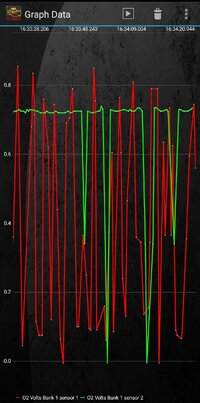

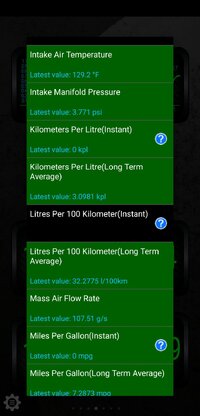

Here's my some of my live data:

P.S.

There's another issue regarding the P0171 which is the idle change usually my truck idles around 600rpm however since this code came up my idle raised to about 900rpm and stays there causing the truck to feel rushed when shift to drive.

Any help is greatly appreciated,

I apologize ahead for opening this thread again I’m sure it has been discussed numerous times but I’m struggling to find the culprit regarding my P0171 code, I have 2004 Trailblazer LT and here’s what I have done so far:

-Vacuum leak checked with a smoke machine and none were found.

-SAIS was deleted and installed a block off plate.

-Replaced O2 upstream sensor.

-Replaced MAP Sensor.

-Tried to tight down intake manifold bolts to the best of my ability and I’ve managed to tighten most of them down however on there was one bolt towards the front of the engine (before the ECM mount) was almost rounded off it seems like someone was on it before (probably the previous owner) so i haven't ruled out the intake manifold yet.

-Cleaned TB and changed the gasket.

-Replaced fuel filter.

-Fuel pressure tested (My readings were 49PSI with key ON and 52PSI with car on idle) also did a leak down test for 10 minutes and no pressure drops.

Here's my some of my live data:

P.S.

There's another issue regarding the P0171 which is the idle change usually my truck idles around 600rpm however since this code came up my idle raised to about 900rpm and stays there causing the truck to feel rushed when shift to drive.

Any help is greatly appreciated,