I have a 2002 Trailblazer that has been neglected as far as oil changes go. Had an oil leak for some time now that I hadn't gotten around to fixing. The vacuum hose that connects to the bottom of the air box resonator on top of the engine from the front of the valve cover has been broken and i've been losing oil there. Also i'm pretty sure the valve cover gasket has been leaking for a while as well. Anyway, i've been getting a metallic rattling sound coming from the engine for quite some time now that was most noticeable just after accelerating when letting off the gas pedal. Recently the sound has gotten much louder and is heard during any RPM's higher than idle in addition to when letting off the gas pedal. The vehicle lacks power now as well and takes longer to get up to speed. I've finally parked the vehicle and stopped driving it so I can try to fix it.

I've pulled the intake manifold and was surprised to see a bunch of oil all over the gasket as well as caked on the inside of the cylinder head intake ports. Also, when pulling the coil packs on top of the valve cover several had a bit of oil which I already knew about but the #5 cylinder had oil just pouring out of the spark plug boot and i'm amazed that cylinder was even working at all now.

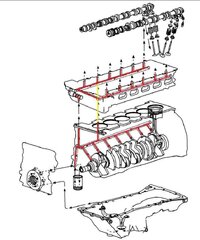

I removed the valve cover and got a look at the cylinder head. I've seen several photos that others have posted of their cylinder head after removing the valve cover and i'm a bit surprised how different mine looks as far as the oil or oil residue that's in the head. I haven't drained the oil yet and my cylinder head looks pretty dry to me. Like it hasn't really been getting the oil it needs in quite some time.

Also, in the front of the cylinder head in the timing chain area the walls are covered in a thick tar like substance, presumable burned oil but really thick and caked on in a way i've never seen in an engine before.

I'm concerned now that maybe there's been a bit more wear and tear in the cylinder head due to lack of oil than I was hoping. I took a close up pic of that shows some of the wear on one of the camshafts.

Does this look like normal camshaft wear?

Nothing so far appears to be physically broken. Would it be a good assumption that the loud rattle like noise i'm hearing when accelerating and decelerating could be lifter noise from lifters not getting the oil they need or maybe even dry?

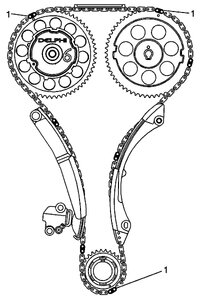

So far i'm thinking a new oil pump and maybe sump filter will be needed. Maybe replace the lifters and possibly the timing chain assembly. Then of course replace gaskets and clean everything up as best I can.

I do plan on removing the oil pan and front cover to get a good look in those areas as well.

Thanks in advance for any feedback anyone may have to offer for me.

I've pulled the intake manifold and was surprised to see a bunch of oil all over the gasket as well as caked on the inside of the cylinder head intake ports. Also, when pulling the coil packs on top of the valve cover several had a bit of oil which I already knew about but the #5 cylinder had oil just pouring out of the spark plug boot and i'm amazed that cylinder was even working at all now.

I removed the valve cover and got a look at the cylinder head. I've seen several photos that others have posted of their cylinder head after removing the valve cover and i'm a bit surprised how different mine looks as far as the oil or oil residue that's in the head. I haven't drained the oil yet and my cylinder head looks pretty dry to me. Like it hasn't really been getting the oil it needs in quite some time.

Also, in the front of the cylinder head in the timing chain area the walls are covered in a thick tar like substance, presumable burned oil but really thick and caked on in a way i've never seen in an engine before.

I'm concerned now that maybe there's been a bit more wear and tear in the cylinder head due to lack of oil than I was hoping. I took a close up pic of that shows some of the wear on one of the camshafts.

Does this look like normal camshaft wear?

Nothing so far appears to be physically broken. Would it be a good assumption that the loud rattle like noise i'm hearing when accelerating and decelerating could be lifter noise from lifters not getting the oil they need or maybe even dry?

So far i'm thinking a new oil pump and maybe sump filter will be needed. Maybe replace the lifters and possibly the timing chain assembly. Then of course replace gaskets and clean everything up as best I can.

I do plan on removing the oil pan and front cover to get a good look in those areas as well.

Thanks in advance for any feedback anyone may have to offer for me.