Could the reason my oil pressure gage is jumpin all over because I added a quart of oil when the stop engine light came on. It went away aftee i added the quart in. Now my gage is all over the place. Oil change tonight anyways, but just a concern thats all?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oil pressure jumpin all over the place?

- Thread starter DENALIV84X4

- Start date

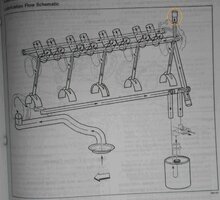

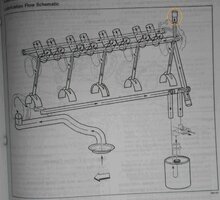

If you look at the object inside of the Yellow/Red Oval Highlighted in the attached image of the Symbolic Oil Flow Diagram for the GM 5.3L Engine... you can see that the Oil Pressure Sending Unit Sensor is the Last Thing In The Oil Flow Line in the Vertical Column of the Oil Travel... situated at a "Dead End". So it is very likely that the Sensor itself is just Clogged ...as it has an in-dwelling Filter Screen Tube with a fine enough Stainless Steel Mesh to preclude that Steady Oil Pressure from ever reaching the Pressure Membrane (Piezo-Electric) if Clogged with Gunk and interrupting that trigger for the sensor signals to reach the PCM:

This is such a simple sensor in a way that its a damned shame it has to be positioned in such an out of the way place on this Motor. The attached Video can help you to get at it with the least amount of trouble. Use ONLY the ACDelco OPS Filter and Sending Unit if you decide to R&R these components. You WILL need to obtain something like this Lisle Model # 13250 OPSU Socket because Standard Deep Sockets will NOT work:

Available on Amazon for around $7.00 + S&H:

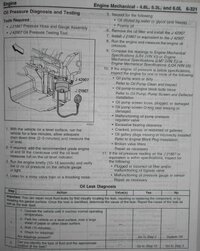

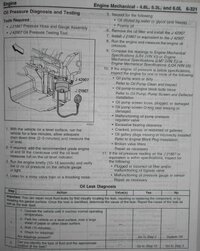

However... if you continue to see very sketchy oil pressure readings on your Instrument Cluster Panel... if the problem is NOT with the Oil Pressure Gauge on that panel itself, then a deeper investigation must be performed. This screen print from the OEM Service Manual shows you the Specialty Tools and Procedures necessary to follow to confirm reading the ACTUAL oil Pressure using an Analog Oil Pressure Gauge and make an accurate determination:

This is such a simple sensor in a way that its a damned shame it has to be positioned in such an out of the way place on this Motor. The attached Video can help you to get at it with the least amount of trouble. Use ONLY the ACDelco OPS Filter and Sending Unit if you decide to R&R these components. You WILL need to obtain something like this Lisle Model # 13250 OPSU Socket because Standard Deep Sockets will NOT work:

Available on Amazon for around $7.00 + S&H:

However... if you continue to see very sketchy oil pressure readings on your Instrument Cluster Panel... if the problem is NOT with the Oil Pressure Gauge on that panel itself, then a deeper investigation must be performed. This screen print from the OEM Service Manual shows you the Specialty Tools and Procedures necessary to follow to confirm reading the ACTUAL oil Pressure using an Analog Oil Pressure Gauge and make an accurate determination:

Last edited:

C-ya

Member

- Aug 24, 2012

- 1,098

Mine was bouncing around after I did a flush and clogged the screen. Cleaned it and back to normal. I'm running Rotella in it now and will probably change it early to get any more junk out. I'm at 60% on my OLM so at about 50% I think I'll change it.

I can change the sensor and the screen in about 5 minutes. If you have large hands it may take longer. I use a long extension with a universal on a ratchet. Unplug the cable, put the socket on it, turn it and then turn it by hand. Take it out, fish the screen out, clean it, put it all back in. I do recommend having extra screens on hand in case you punch a hole in one whilst fishing it out.

I can change the sensor and the screen in about 5 minutes. If you have large hands it may take longer. I use a long extension with a universal on a ratchet. Unplug the cable, put the socket on it, turn it and then turn it by hand. Take it out, fish the screen out, clean it, put it all back in. I do recommend having extra screens on hand in case you punch a hole in one whilst fishing it out.

If you look at the object inside of the Yellow/Red Oval Highlighted in the attached image of the Symbolic Oil Flow Diagram for the GM 5.3L Engine... you can see that the Oil Pressure Sending Unit Sensor is the Last Thing In The Oil Flow Line in the Vertical Column of the Oil Travel... situated at a "Dead End". So it is very likely that the Sensor itself is just Clogged ...as it has an in-dwelling Filter Screen Tube with a fine enough Stainless Steel Mesh to preclude that Steady Oil Pressure from ever reaching the Pressure Membrane (Piezo-Electric) if Clogged with Gunk and interrupting that trigger for the sensor signals to reach the PCM:

View attachment 89495

This is such a simple sensor in a way that its a damned shame it has to be positioned in such an out of the way place on this Motor. The attached Video can help you to get at it with the least amount of trouble. Use ONLY the ACDelco OPS Filter and Sending Unit if you decide to R&R these components. You WILL need to obtain something like this Lisle Model # 13250 OPSU Socket because Standard Deep Sockets will NOT work:

View attachment 89497

Available on Amazon for around $7.00 + S&H:

However... if you continue to see very sketchy oil pressure readings on your Instrument Cluster Panel... if the problem is NOT with the Oil Pressure Gauge on that panel itself, then a deeper investigation must be performed. This screen print from the OEM Service Manual shows you the Specialty Tools and Procedures necessary to follow to confirm reading the ACTUAL oil Pressure using an Analog Oil Pressure Gauge and make an accurate determination:

View attachment 89496

So much detail! It ended up being a clogged screen. All cleaned up. No more bouncing around. Thanks for the repliss everyone!