Oh brother, this has become a saga. I decided not to do the repair myself, no lift and just a wee bit beyond what felt confident doing, having no actual experience with this repair. I took it to my backup mechanic, honest and trustworthy, but not inexpensive either, but ain’t that about par for the course too?

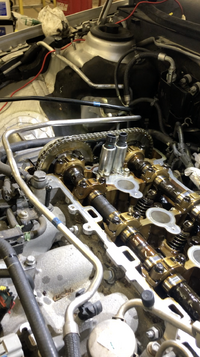

His quote based inspection of the work required, is $1550 for the 9-4201vvt kit installed. He hasn’t started on it yet as we just arrived at the quote yesterday but today, the rethinking begins. I have requested he hold up pending further discussion of the specifics of his diagnosis to confirm what I reported as a likely tension issue. Back to the code P2090, I tell you my friend, if one can believe in the code description, the words “circuit low” bothers me. Further regurgitation and thoughts, in addition to the repair cost, is diverting my attention to what diagnosis was performed concerning the fricking circuit? Was the cam position sensor signal probed for amplitude and waveform was continuity confirmed between the position sensor and the ECM? I didn’t do this, and now I think I should have. I don’t have a bidirectional scanner but I have a scope and I know how to use it. Did I simply presume something I should not have? Having to ask that question now is my fault, without a doubt, but if my mechanic didn’t confirm this, it’s time to do it now, before a wrench is turned. I agreed to proceed with the repair based on what? Your input has been invaluable and in no manner would I attempt to second guess it. I think you would agree that with this code, presumptions I made by not confirming a possible defective replacement sensor or a possible electrical issue (circuit low) between the sensor and ECM, must be eliminated. Perhaps the mechanic didn’t either. So that’s what I will need to confirm Monday before proceeding. My mechanic is no special wonder, he has to exercise the same steps as everyone else and considering he hasn’t ever done this repair on a VVT, we both need additional confirmation before proceeding.

I will ask your confirmation on one point if you haven’t already decided I’m crazy, I believe the cam position sensor is biased by the 5v supply which the ECM can track as the sensor output becomes superimposed on the 5v bias. Assuming this to be correct, if there is a true circuit issue as reported by the DTC, it has to be confined to the sensor/ECM connection nothing else. Can you confirm? The very last thing I want is a huge repair bill and the code is still there. That’s going to be painful for me and the mechanic! I don’t want to go there ever!

I’ll keep you posted.

Thanks a million