Hello guys,

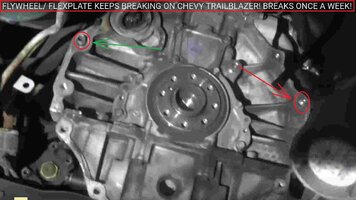

I purchased a new to me 2005 Trailblazer about a month ago. The previous owner told me that the transmission was overhauled recently. Indeed, the transmission operates quite good. However, there is a slight knocking sound from the bellhousing. I think that the flexplate is broken, probably during the installation of the transmission. How can I diagnose this? Also, is it possible to replace the flexplate without removing the transmission? For example, by supporting the transmission and using a pair of long bolts instead of the original bolts that connect the bellhousing to the motor? Could it be done with a jack and some jack stands?

Another problem that I discovered - the truck stalled several times. A couple of times it happened when I put on the reverse gear, and about 3-4 times it happened on the street light, when I removed the foot from the brake pedal and pressed on the accelerator pedal. It seems that it happens only when the A/C is on. I disassembled the throttle body - it was not so dirty. I cannot replicate the problem since then, but I am not completely sure that the cleanng of the throttle body solved the problem. There are no fault codes. What it could be and is there a possibility that the problem of stalling is somehow related to the knocking noise (potentially broken flexplate)?

Thanks!

I purchased a new to me 2005 Trailblazer about a month ago. The previous owner told me that the transmission was overhauled recently. Indeed, the transmission operates quite good. However, there is a slight knocking sound from the bellhousing. I think that the flexplate is broken, probably during the installation of the transmission. How can I diagnose this? Also, is it possible to replace the flexplate without removing the transmission? For example, by supporting the transmission and using a pair of long bolts instead of the original bolts that connect the bellhousing to the motor? Could it be done with a jack and some jack stands?

Another problem that I discovered - the truck stalled several times. A couple of times it happened when I put on the reverse gear, and about 3-4 times it happened on the street light, when I removed the foot from the brake pedal and pressed on the accelerator pedal. It seems that it happens only when the A/C is on. I disassembled the throttle body - it was not so dirty. I cannot replicate the problem since then, but I am not completely sure that the cleanng of the throttle body solved the problem. There are no fault codes. What it could be and is there a possibility that the problem of stalling is somehow related to the knocking noise (potentially broken flexplate)?

Thanks!