*Amplifying*

(Pun Intended here) upon the information covered in Post #85 & #86... I thought I would array

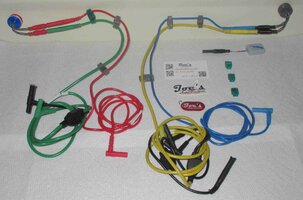

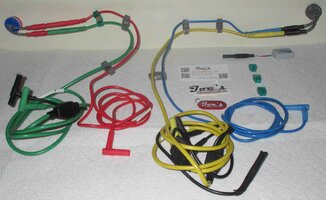

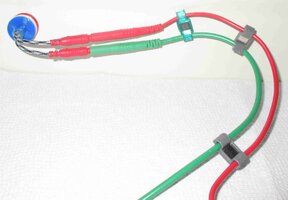

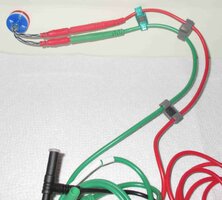

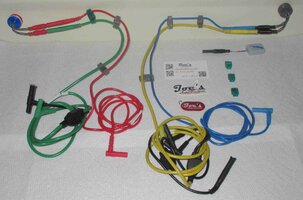

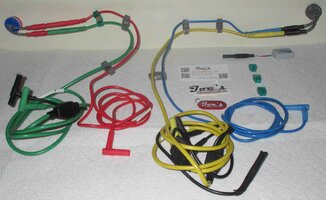

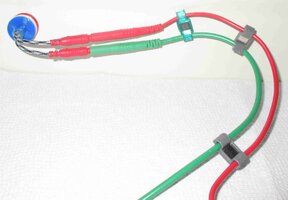

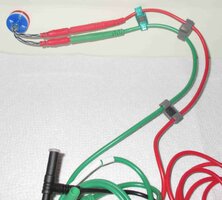

TWO "Joe's Auto Electric" Magnetically Held Vibration Sensors along the Back-Plane of my Ceramic Painted Oven Deck along with a few of his

VERY Handy -2 - Have

Neodymium Magnetic Oscilloscope Leads Holders that would be necessary to array them on say... under the Steel Frame-Chassis Sections or Stuck to the Brake Assembly Dust Plates on the backs of any of the Four Wheels... or underneath the Suspension, Engine or Transmission Mounts Steel Brackets... or Wherever

You NAME IT.

Getting this Inexpensive Support Hardware and Using these Tactics for deployment of them on or under your vehicle(s) is

all very necessary *IF* you intend upon making

ANY serious efforts at conducting

Automotive Vibration Analysis in

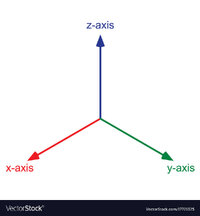

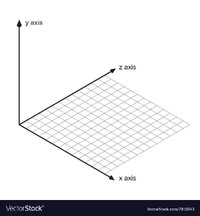

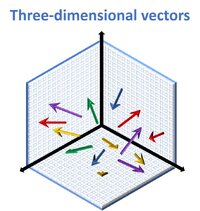

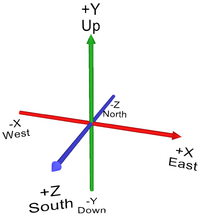

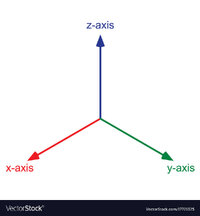

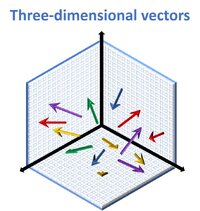

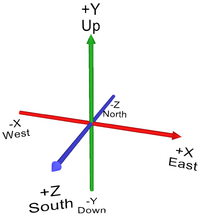

ANY of the Three Degrees of Freedom of Motion in The "X"... The "Y" ...or The "Z" Vectors

(or any combinations in between) that Automotive Components can create... simply by using

YOUR Oscilloscope for such Diagnostics:

Beyond post-inspection observations of clearly Broken Components, I don't care

HOW sensitive and subtle you

MIGHT think that your "Inner Ear gauge & Meter" or your "Seat-Of-The-Pants" Vibration Detection Apparatus might be... I defy

ANYONE to explain

precisely Which Components

(or any combinations thereof) is

(are) either causing or contributing to the creation of Mysterious, often Impossible to Locate Vibrations and the Strange Noises they can generate... with any

True Degree of Accuracy.

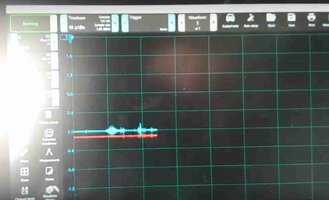

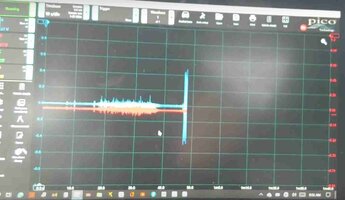

All that said... if you possess either a One, Two, Four or Eight Channel Oscilloscope and THIS Gear... then you can isolate certain suspect components in their Proper X,Y & Z Vectors of Motion...

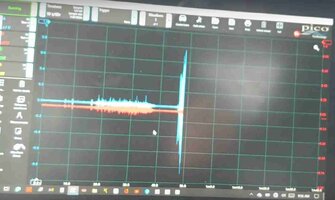

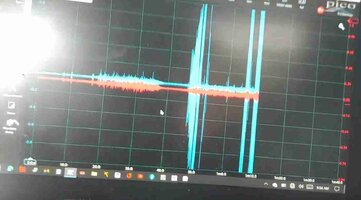

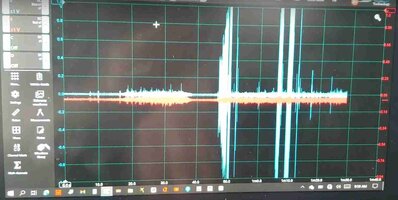

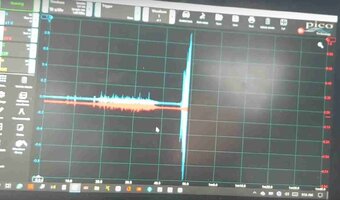

and THEN your Oscilloscope Screen WILL reveal whatever activity is actually taking place.

Now, while I honestly don't believe that it is

necessary to take the

MIT Mechanical Engineering Course shown in this Linked Video to understand the basics of all this stuff... I suspect that if you have the wherewithal to be reading THIS Topic right now... then you have already Drunk The "O" Scope Kool-Aid by now and are neither afraid to

TRY TO DO NEW THINGS, nor afraid of

LEARNING HOW TO DO NEW THINGS... and You've already done so ...time and again!.

Nonetheless... Please... Give this

Low-Key (BUT Very COOL) MIT Professor half-a-chance at around 34 Minute into his Lecture and you'll be surprised at just how much of what he describes to his students ....is already nested within your Mechanic's Mental Wheelhouse of Understanding:

MIT Mechanical Engineering Course on Vibration:

Covering A Single Degree of Freedom

Vibration Isolation:

Also... Attached below is another "On Topic" White Paper worth digesting that provides even

more insights into Vibration Diagnostics and Analysis:

In the end... Even if you

NEVER delve any deeper into this subject than simply placing your Oscilloscope Vibration Sensors 'hither and yon" ... BUT... carefully observe WHERE and observe WHICH VECTOR(S) (X.Y,Z) they wind up being properly situated (pointed) at upon or near to each Suspect Component ....then your Oscilloscope WILL display them as

Amplitude vs. Frequency Over Time and THEN you will

EASILY figure out the problem from watching

"ALL THOSE SQUIGGLES" on your Screen...WHAT Component(s)n are causing the Problems and showing WHEN they started to FAIL (at Certain RPM... During Certain Braking Events... in Certain Gears, Etc.)

THIS Process is a

MUCH better approach than merely

GUESSING and

THEN wind up Buying Suspension Parts, Etc... and

LATER finding out that what You

THOUGHT were the *Problem Parts* or components turned out

NOT to be what was Causing all that

RACKET and all those Premature Parts Failures. :>)