Hello everyone! I have a 07 TB 4.2 I recently got a p0411 code which didn't really cause any issue figured it was a small vacuum leak reset code and had no performance issues. Changed oil on Sun (probably unrelated but im not sure at this point) drove it on Tues night and it suddenly began having a very loud squealing sound when accelerating and some hesitation especially on start up sounds as if it wants to die. Thought of belt or any of the pulleys however i removed the belt and revved engine to 3k rpm and still have this sound so figure that rules out any of those components. If anyone has any ideas of how to rectify this I would greatly appreciate it. Thank you

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help with a p0411 code

- Thread starter Daryl Krenzer

- Start date

Perhaps this is one of those times that only making a clear Video/Audio will help with the diagnosis. If you can get someone to raise the RPM slowly up to at least 3,000...and then slowly back down to try and duplicate this bizarre sound while you record this event... Once you Post that file back here as a YouTube Link ...then after other Members have had the chance to listten to it and iterpret what is happening... may prove to be more revealing.

Thanks I'll try that. Im thinking now it may be a bad throttle body I saw a video of one making the exact same sound

Mooseman

Moderator

That is a code related to the SAIS (Secondary Air Injection System). A basic search would have yielded several threads on the subject:

gmtnation.com

gmtnation.com

Search results for query: p0411

Thanks I did read through a few of those and actually changed both components and inspected the hoses which are in great shape however still have this ridiculously loud screech. When in motion it only occurs when accelerating otherwise smooth and quiet.

Mooseman

Moderator

Are you still getting the code?

If possible, a video.or recording of the noise would be helpful. The SAIS wouldn't be responsible for it because it only works at startup when cold. Apart from something belt driven, i can't see how anything else could make such a sound.

If possible, a video.or recording of the noise would be helpful. The SAIS wouldn't be responsible for it because it only works at startup when cold. Apart from something belt driven, i can't see how anything else could make such a sound.

Code hasn't returned but only driven a few blocks as that sound is quite loud and being unsure of cause i dont want to put many miles on it...ill be able to get a video on Sun. Ive already ruled out belt driven items as this sound still occurs with the belt removed and revved to 3k rpm. Only thing i can think of is throttle body issue with the plate or the mechanism that controls it. I plan to remove it tonight clean and inspect it however I dont have the means to bench test it.

I know how frustrating this situation must be for you... So please don't take offense to these suggestions. The way sounds can be bounced around and re-directed in, around and under the any Engine Bay might suggest looking further back and underneath the vehicle for the source of this problem. You will need to perform this Video Recording with the Vehicle Jacked up and Resting on Jack Stands or better yet, Heavy Duty Truck Ramps for this Inspection. Follow these Safety Protocols:

(1) Ensure that the Vehicle Shifter is 'deliberately' placed into the PARK Position. Double Check!

(2) Chock the Rear Wheel s in Front and in Back with Over-Sized Chocks from Harbor Freight.

(3) Perform the "Push and Shake" Test once the Vehicle is on Jack Stands and Visually Re-Inspect!

(4) Start the Engine at Idle and Record the Ambient sounds Above, Around & Beneath the Engine.

(5) Have a Reliable, Person Step slowly on the ACC Pedal & Raise it to 3,000 RPM.

(6) Use your Extended Arm to Guide the REC Video Camera around and underneath the SUV.

(7) Do NOT Crawl Under The Vehicle at ANY Time during the Video Audio Recording!

(8) Be Safe ...and Post the Video back in this Thread.

(1) Ensure that the Vehicle Shifter is 'deliberately' placed into the PARK Position. Double Check!

(2) Chock the Rear Wheel s in Front and in Back with Over-Sized Chocks from Harbor Freight.

(3) Perform the "Push and Shake" Test once the Vehicle is on Jack Stands and Visually Re-Inspect!

(4) Start the Engine at Idle and Record the Ambient sounds Above, Around & Beneath the Engine.

(5) Have a Reliable, Person Step slowly on the ACC Pedal & Raise it to 3,000 RPM.

(6) Use your Extended Arm to Guide the REC Video Camera around and underneath the SUV.

(7) Do NOT Crawl Under The Vehicle at ANY Time during the Video Audio Recording!

(8) Be Safe ...and Post the Video back in this Thread.

Thank you guys ill see if i can pull that off. I actually changed oil on Sun prior to this issue and was worried i didnt fill it completely or that the 7 quarts where somehow not enough but ive checked it on flat ground and its full.

Those are arguably The BEST Audio Diagnostic Videos we've ever seen. Well Done, Brother! Even though it may be that Royal Purple is NOT on the List of Approved GM Lubricants for the Atlas Engine... I doubt that your use of of Royal Purple Motor Oil is at Issue here. My suspicions lay in these areas:

(1) The Bendix Starter Small Gear and Return Spring may have weakened enough to allow that Loose Gear to Brush up against the Outer Fire Ring at Higher RPM and make enough Friction Contact via Metal to Metal contact to create a sort of "Nails on a Black Board" kind of vibration.

(2) The Flex-Plate is Cracked and likewise pieces near the Axis of Rotation may brushing up against a portion of the Back of the Engine or Bell Housing.

(3) One or more of the Three (3) 120 Degree Separated 10.9 Hard Bolts holding the Torque Converter to the Flywheel are LOOSE and allowing a mis-aligned Flex-Plate to glide back and forth on the TQ Bolt Shaft(s) ...inducing a similar "Metal to Metal" oscillation and vibration into the Flex-Plate.

(4) There might be something in-on-near the Rotating Valve Train close to the #5 and #6 Cylinders that has either broken loose or is laying close enough to a Rotating portion of the camshafts to make direct contact and create this noise at higher RPM under the Valve Cover.

(5) The Main Thrust Bearing may be worn to the point of allowing the Crankshaft to move excessively beyond Engine Tolerances ... in and out ... longitudinally and can allow either the Flex-Plate to make contact at its outer edges with the Bell Housing... or the Harmonic Balancer to make contact with the Front Timing Cover and cause the rotational Vibrations to only occur at Higher RPM.

It is important to remember that the Crankshaft Torsion causes it to constantly 'Hunt" ... inwards and outwards... up and down the RPM Scale... and too much "Freedom" in this action can allow the External Bolt-On components of the Rotating Assembly to come into Direct Contact with the Front and Rear Rigid portions of this Atlas Engine Block and Bell Housing.

The Harmonic Balancer PLUS the Special Washer in front of it along with Very Proper Torque and TTY tightening procedures to the Nose of the Crankshaft takes care of this problem at the very FRONT of the Engine. The Correct procedures require Tightening a NEW Crankshaft TTY Bolt to 110 Foot Pounds... and then an additional Torque To Yield effort must be applied by 180 Degrees of Added Bolt Rotation. Nothing Less Will Do.

Meanwhile... it is the Internal Crankshaft Thrust Bearing on the 5th Journal of the Crankshaft Mains that keeps the Flex-Plate under proper distance control at the REAR side of the Engine Block.

(1) The Bendix Starter Small Gear and Return Spring may have weakened enough to allow that Loose Gear to Brush up against the Outer Fire Ring at Higher RPM and make enough Friction Contact via Metal to Metal contact to create a sort of "Nails on a Black Board" kind of vibration.

(2) The Flex-Plate is Cracked and likewise pieces near the Axis of Rotation may brushing up against a portion of the Back of the Engine or Bell Housing.

(3) One or more of the Three (3) 120 Degree Separated 10.9 Hard Bolts holding the Torque Converter to the Flywheel are LOOSE and allowing a mis-aligned Flex-Plate to glide back and forth on the TQ Bolt Shaft(s) ...inducing a similar "Metal to Metal" oscillation and vibration into the Flex-Plate.

(4) There might be something in-on-near the Rotating Valve Train close to the #5 and #6 Cylinders that has either broken loose or is laying close enough to a Rotating portion of the camshafts to make direct contact and create this noise at higher RPM under the Valve Cover.

(5) The Main Thrust Bearing may be worn to the point of allowing the Crankshaft to move excessively beyond Engine Tolerances ... in and out ... longitudinally and can allow either the Flex-Plate to make contact at its outer edges with the Bell Housing... or the Harmonic Balancer to make contact with the Front Timing Cover and cause the rotational Vibrations to only occur at Higher RPM.

It is important to remember that the Crankshaft Torsion causes it to constantly 'Hunt" ... inwards and outwards... up and down the RPM Scale... and too much "Freedom" in this action can allow the External Bolt-On components of the Rotating Assembly to come into Direct Contact with the Front and Rear Rigid portions of this Atlas Engine Block and Bell Housing.

The Harmonic Balancer PLUS the Special Washer in front of it along with Very Proper Torque and TTY tightening procedures to the Nose of the Crankshaft takes care of this problem at the very FRONT of the Engine. The Correct procedures require Tightening a NEW Crankshaft TTY Bolt to 110 Foot Pounds... and then an additional Torque To Yield effort must be applied by 180 Degrees of Added Bolt Rotation. Nothing Less Will Do.

Meanwhile... it is the Internal Crankshaft Thrust Bearing on the 5th Journal of the Crankshaft Mains that keeps the Flex-Plate under proper distance control at the REAR side of the Engine Block.

Last edited:

it certainly doesn't sound "nice". The noise at idle sounds a little "rough". The squeal at revs is even worse. I am sure there are a few things that you could potentially check. Although your video seems to have "isolated" the sound toward the rear, you might consider getting a mechanics stethoscope and try listening to some of the area to see if you can pinpoint things a bit more. You might pull the two rear plugs to see if their color indicate anything. Maybe if possible, do some compression checks.

The new code gives some "hope" (not sure at this point that's the right word) that there is a problem higher in the engine as the things that mrrsm mention have little or no way to cause an "emission issue" (except item 4). I would also check the exhaust manifold for cracks (my "experience", another story).

The new code gives some "hope" (not sure at this point that's the right word) that there is a problem higher in the engine as the things that mrrsm mention have little or no way to cause an "emission issue" (except item 4). I would also check the exhaust manifold for cracks (my "experience", another story).

Thanks for the help. I've decided to get it into a shop think this is beyond my capabilities. Not sure if dealer or independent shop is better option I at least need to get it diagnosed to decide if its worth the trouble. I sure hope it is love this damn thing and have put tons of time into maintaining and repairing it...just paid it off too. Ugh. Really appreciate all the effort and advise.! 👏

Those are arguably The BEST Audio Diagnostic Videos we've ever seen. Well Done, Brother! Even though it may be that Royal Purple is NOT on the List of Approved GM Lubricants for the Atlas Engine... I doubt that your use of of Royal Purple Motor Oil is at Issue here. My suspicions lay in these areas:

(1) The Bendix Starter Small Gear and Return Spring may have weakened enough to allow that Loose Gear to Brush up against the Outer Fire Ring at Higher RPM and make enough Friction Contact via Metal to Metal contact to create a sort of "Nails on a Black Board" kind of vibration.

(2) The Flex-Plate is Cracked and likewise pieces near the Axis of Rotation may brushing up against a portion of the Back of the Engine or Bell Housing.

(3) One or more of the Three (3) 120 Degree Separated 10.9 Hard Bolts holding the Torque Converter to the Flywheel are LOOSE and allowing a mis-aligned Flex-Plate to glide back and forth on the TQ Bolt Shaft(s) ...inducing a similar "Metal to Metal" oscillation and vibration into the Flex-Plate.

(4) There might be something in-on-near the Rotating Valve Train close to the #5 and #6 Cylinders that has either broken loose or is laying close enough to a Rotating portion of the camshafts to make direct contact and create this noise at higher RPM under the Valve Cover.

(5) The Main Thrust Bearing may be worn to the point of allowing the Crankshaft to move excessively beyond Engine Tolerances ... in and out ... longitudinally and can allow either the Flex-Plate to make contact at its outer edges with the Bell Housing... or the Harmonic Balancer to make contact with the Front Timing Cover and cause the rotational Vibrations to only occur at Higher RPM.

It is important to remember that the Crankshaft Torsion causes it to constantly 'Hunt" ... inwards and outwards... up and down the RPM Scale... and too much "Freedom" in this action can allow the External Bolt-On components of the Rotating Assembly to come into Direct Contact with the Front and Rear Rigid portions of this Atlas Engine Block and Bell Housing.

The Harmonic Balancer PLUS the Special Washer in front of it along with Very Proper Torque and TTY tightening procedures to the Nose of the Crankshaft takes care of this problem at the very FRONT of the Engine. The Correct procedures require Tightening a NEW Crankshaft TTY Bolt to 110 Foot Pounds... and then an additional Torque To Yield effort must be applied by 180 Degrees of Added Bolt Rotation. Nothing Less Will Do.

Meanwhile... it is the Internal Crankshaft Thrust Bearing on the 5th Journal of the Crankshaft Mains that keeps the Flex-Plate under proper distance control at the REAR side of the Engine Block.

Thank you again for your help. I have read through your reply again i think I was a bit overwhelmed by all that info lol. The first 3 items you mentioned seem like i may be able to at least try digging into those so if i remove the the starter can you tell by visually inspecting it if this the cause? With starter d/c can you turn the flex plate to inspect it? And lastly is it possible to tighten those bolts on torque converter without removing major components? Thanks again

At this point... I am dis-inclined to suggest that you open up any areas of the Engine-Drive Train for performing serious mechanical tear downs to locate this problem. Given your reticence to run headlong into tearing into the "Undiscovered Country" of these Potential Problem areas... the practical alternative would be to take it to a Reliable Auto Repair Shop and ask them to do a "Flat Rate" Investigation... BUT WITHOUT AUTHORIZING THEM TO DO ANY ACTUAL REPAIRS. You simply want them to Identify any problems... but absolutely take No Action of Component Dis-Assembly.

Once a Trained Mechanic has the Vehicle on the Lift and Identifies what he thinks the problem is... Then you can decide if it would be cheaper and easier in the long run to pay a Professional to do any repairs. Do NOT allow the Shop Mechanic to suggest doing ANY other Repairs while they hold your SUV "Hostage" on that Lift! Make sure they agree to a "Flat Rate" Investigatory Fee.

If you insist on going forward... I would suggest that you NOT "Start" with the "Starter". Instead... Safely elevate the vehicle and after ensuring that it rests good and solid on Jack Stands. Next, slide some Cardboard under the engine area for you to lay down on and move yourself into a position to "I-Ball" the mating areas underneath and between the Back of the Engine Block and the Bell Housing-Transmission. Now... look Dead Center at the Back edge of the Crankcase for a Small Round Black Plug ...and Pry and Pull it out. That Hole is the Access Port that allows you to slip a 15 MM Socket through there and when the (3) Torque Converter Bolts get aligned... You can check whether or not they are Loose.

But before you can do that....look underneath and a little further back and your will see two of the same sized Black Rubber Plugs connected along a Narrow Slot between the Back of the Engine Block and the Transmission Bell Housing. If you Pull that (those) Plugs out... you will be able to get a Large Flat Blade Screw Driver in that area...and Carefully Pry Rotate the Teeth of the Flywheel in that area... Turning the Flex-Plate Clockwise when facing the front of the SUV.

At the Same Time... Use a Bright Flashlight to observe in the small hole as the (3) Torque Converter Bolts come gradually around and into view in the port flange os the Crankcase-Oil-Pan. Slip your 15 MM Deep Socket over each TC Bolt and TEST to see if any are loose as you SLOWLY apply a Clockwise effort with a Ratchet in Very Small Increments to observe if any of them move at all.

If they do... Back the ones that are loose outwards a bit... and then USE A TORQUE WRENCH to Tighten them Down. It is VERY Important that you AVOID OVER-TIGHTENING THE TORQUE CONVERTER BOLTS. @Mooseman 's Engine FAQ in the GM 4.2L Engine Section has a listing of ALL Engine Torque Specs for tightening fasteners properly.

After tightening any TC Bolts that are loose... REPLACE THOSE THREE RUBBER-PLASTIC PORT PLUGS and then Start the Vehicle at idle and allow the Engine to completely warm up B4 you re-do the 3,000 RPM "Squeal Test". If the Sound has abated... Problem Solved. If not... I would NOT go through the Aggravation of having to Pull the Starter on a Trailblazer-Envoy unless my plan was to just replace it with a Brand New HQ Starter.

There will be no way for you to diagnose the Strength or Weakness of the Bendix Gear-Spring Mechanism... and since BOTH the Small Gear AND the Fire Ring Teeth at the Outer edges of the Flex-Plate are made of Very Tough, Heat Treated, Hardened Steel... there may NOT be any signs of their Friction Contact doing any damage.

Once a Trained Mechanic has the Vehicle on the Lift and Identifies what he thinks the problem is... Then you can decide if it would be cheaper and easier in the long run to pay a Professional to do any repairs. Do NOT allow the Shop Mechanic to suggest doing ANY other Repairs while they hold your SUV "Hostage" on that Lift! Make sure they agree to a "Flat Rate" Investigatory Fee.

If you insist on going forward... I would suggest that you NOT "Start" with the "Starter". Instead... Safely elevate the vehicle and after ensuring that it rests good and solid on Jack Stands. Next, slide some Cardboard under the engine area for you to lay down on and move yourself into a position to "I-Ball" the mating areas underneath and between the Back of the Engine Block and the Bell Housing-Transmission. Now... look Dead Center at the Back edge of the Crankcase for a Small Round Black Plug ...and Pry and Pull it out. That Hole is the Access Port that allows you to slip a 15 MM Socket through there and when the (3) Torque Converter Bolts get aligned... You can check whether or not they are Loose.

But before you can do that....look underneath and a little further back and your will see two of the same sized Black Rubber Plugs connected along a Narrow Slot between the Back of the Engine Block and the Transmission Bell Housing. If you Pull that (those) Plugs out... you will be able to get a Large Flat Blade Screw Driver in that area...and Carefully Pry Rotate the Teeth of the Flywheel in that area... Turning the Flex-Plate Clockwise when facing the front of the SUV.

At the Same Time... Use a Bright Flashlight to observe in the small hole as the (3) Torque Converter Bolts come gradually around and into view in the port flange os the Crankcase-Oil-Pan. Slip your 15 MM Deep Socket over each TC Bolt and TEST to see if any are loose as you SLOWLY apply a Clockwise effort with a Ratchet in Very Small Increments to observe if any of them move at all.

If they do... Back the ones that are loose outwards a bit... and then USE A TORQUE WRENCH to Tighten them Down. It is VERY Important that you AVOID OVER-TIGHTENING THE TORQUE CONVERTER BOLTS. @Mooseman 's Engine FAQ in the GM 4.2L Engine Section has a listing of ALL Engine Torque Specs for tightening fasteners properly.

After tightening any TC Bolts that are loose... REPLACE THOSE THREE RUBBER-PLASTIC PORT PLUGS and then Start the Vehicle at idle and allow the Engine to completely warm up B4 you re-do the 3,000 RPM "Squeal Test". If the Sound has abated... Problem Solved. If not... I would NOT go through the Aggravation of having to Pull the Starter on a Trailblazer-Envoy unless my plan was to just replace it with a Brand New HQ Starter.

There will be no way for you to diagnose the Strength or Weakness of the Bendix Gear-Spring Mechanism... and since BOTH the Small Gear AND the Fire Ring Teeth at the Outer edges of the Flex-Plate are made of Very Tough, Heat Treated, Hardened Steel... there may NOT be any signs of their Friction Contact doing any damage.

Thank you very much sir your knowledge is very much appreciated. We decided to concede defeat on this and took it to a shop for diagnosing with the explicit instructions of diagnose only. Can update on outcome if curious. Once again i cannot express how much i appreciate the help you've given

C-ya

Member

- Aug 24, 2012

- 1,098

Thank you very much sir your knowledge is very much appreciated. We decided to concede defeat on this and took it to a shop for diagnosing with the explicit instructions of diagnose only. Can update on outcome if curious. Once again i cannot express how much i appreciate the help you've given

Please update. I think there are a few curious folks now.

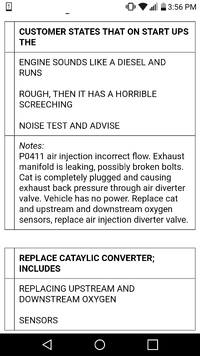

So got a diagnoses from shop. I attached a screenshot. Seems as tho cat is clogged completely sending exhaust back through the valve causing the gasket to erode which I guess caused a lean condition and the half burnt gas smell as well as the high pitched squeals when RPM got to certain point due to the pressure. Either way happy its not internal or transmission. However they are quoting 1800$ and will also be doing a trans service and all has a 24 month warranty. So not best outcome but could have been a whole lot worse. Anyone had this work done and does price sound about right? Thanks guys

Attachments

??? while the diag on the p0171 sounds OK... I am not sure they address the noise part at all... but maybe. IF I understand the report, they are saying your cat is plug... BUT that doesn't happen overnight... usually over time, people start to notice that the vehicle can't speed up as the back pressure causes issues with the engine receiving incoming air / fuel. Did you notice this issue???? In terms of replacing a cat, they ain't cheap and there is some significant cutting and "gluing" involved unless the whole system is replaced.

Yea they are replacing exhaust manifold and cat up to point of muffler. I wasn't main driver mostly wifey drove it so I wouldn't notice as much. I felt that was a bit strange too seemed pretty abrupt but maybe it had been building and it finally got to that point and blew out the exhuast gasket I'm not sure really but if they tear it down and replace these parts and its back to its old self ill be happy...except about the cost of course haha

Mooseman

Moderator

I guess it could make a kind of whistling noise with the back pressure and it's backing up into the SAIS valve. Hopefully the manifold isn't cracked as well.

Yea me too service tech is planning as if it is and ordered a new one but hopefully only a new gasket will be needed its the damn cat that's so damn expensive and removing the manifold looks like a major PITA.

I have gone through this P0411 code numerous times. I now have it again for the 5th or 6th time, with my 08 trailblazer. I replaced the relay (under driver side chassis) and seemed to work well for a month or so, now again getting code. I can hear the air pump kick in occasionally. Is it possible for the relay to work intermittently?? Thanks for the help.That is a code related to the SAIS (Secondary Air Injection System). A basic search would have yielded several threads on the subject:

Search results for query: p0411

gmtnation.com

Hello so i ended up changing air injection check valve which cleared things up. Its a pretty easy swap 2 13mm bolts and 1 10mm bolt that hold tranny dipstick

I have gone through this P0411 code numerous times. I now have it again for the 5th or 6th time, with my 08 trailblazer. I replaced the relay (under driver side chassis) and seemed to work well for a month or so, now again getting code. I can hear the air pump kick in occasionally. Is it possible for the relay to work intermittently?? Thanks for the help.

Mooseman

Moderator

Best fix is to delete the SAIS and have the codes turned off with a tune.