How prone is the exhaust manifold to failure on I-6? I have a loud exhaust noise coming from that general area. Can not see a thing, every thing jammed in there but the kitchen sink. Got to do the plugs, clean the TB and MAP so I figure I will pull off the heat shield and see whats up. Any good threads of removal and replacement? Thanks Greg.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Exhaust manifold

- Thread starter pell

- Start date

Its fairly common. I believe the consensus is to replace, and not repair. But you need to be sure its the manifold, and not the doughnut, or a broken manifold stud.

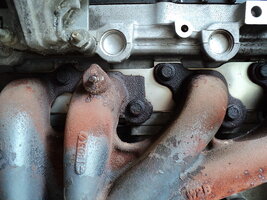

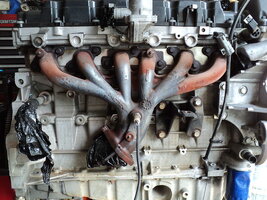

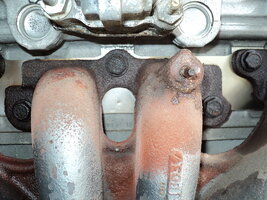

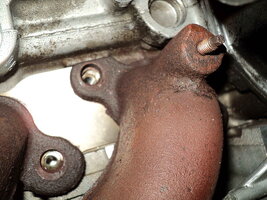

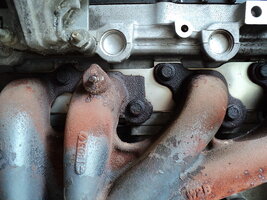

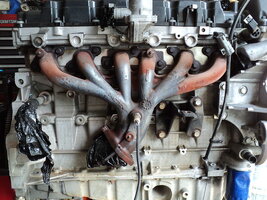

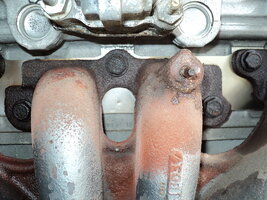

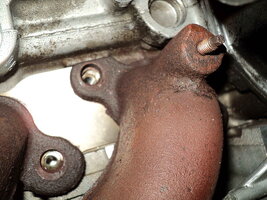

Here are some images I took of the Artifacts of Failure for the Exhaust Manifold on a 2004 Chevrolet Trailblazer 4.2L Engine (165,000 Miles) with the GM OEM Cast Iron Exhaust Manifold installed:

The Primary Things to look for...

(1) The Popping and Sputtering Noises from the Engine that changes as the Motor comes up to Operational Temperature and the Exhaust Manifold expands from High Heat to partially close up the Gaps or Cracks in between the various cast piping sections...primarily cracking in the 'The Dog Leg' area where the Pipe Segments meet up and the heat concentrates. Notice that their is consequential Rust Flaking from excessive flexing that occurs to gradually Reduce the thickness and strength of the Cast Iron in that area.

(2) A Golden Rusty Patina on the Multi Layered Stainless Steel Gasket and around the EM Tangs where the Fasteners have snapped off flush with the facing of the Aluminum Engine Head where the Cast Iron actually WARPS... but the Bolts remain STUCK or jammed inside of their Bolt Holes in the EM Flange ends, hiding their Failures.

(3) Having BAD OR COLLAPSED MOTOR MOUNTS will accelerate this failure as the Engine and Transmission roll and gyrate Left & Right under acceleration and deceleration. These countless Side to Side motions move beyond the ability of the Exhaust Manifold Bolts to resist these flex actions, eventually work hardening the M8 X 1.25 X 30mm Fasteners to the point of Failure. Take notice that in the areas having the Greatest Amount of Flexing that the Metal appears Blue-Black. This is because the top coat of Rusted Metal Flakes off each time the Engine goes from Cold to HOT and back to Cold.

The Primary Things to look for...

(1) The Popping and Sputtering Noises from the Engine that changes as the Motor comes up to Operational Temperature and the Exhaust Manifold expands from High Heat to partially close up the Gaps or Cracks in between the various cast piping sections...primarily cracking in the 'The Dog Leg' area where the Pipe Segments meet up and the heat concentrates. Notice that their is consequential Rust Flaking from excessive flexing that occurs to gradually Reduce the thickness and strength of the Cast Iron in that area.

(2) A Golden Rusty Patina on the Multi Layered Stainless Steel Gasket and around the EM Tangs where the Fasteners have snapped off flush with the facing of the Aluminum Engine Head where the Cast Iron actually WARPS... but the Bolts remain STUCK or jammed inside of their Bolt Holes in the EM Flange ends, hiding their Failures.

(3) Having BAD OR COLLAPSED MOTOR MOUNTS will accelerate this failure as the Engine and Transmission roll and gyrate Left & Right under acceleration and deceleration. These countless Side to Side motions move beyond the ability of the Exhaust Manifold Bolts to resist these flex actions, eventually work hardening the M8 X 1.25 X 30mm Fasteners to the point of Failure. Take notice that in the areas having the Greatest Amount of Flexing that the Metal appears Blue-Black. This is because the top coat of Rusted Metal Flakes off each time the Engine goes from Cold to HOT and back to Cold.

Last edited:

TequilaWarrior

Member

Of possible interest:

gmtnation.com

gmtnation.com

Pay particular attention to the difficulties had during the removal process.

Exhaust Manifold Replacment - input requested

I've finally had enough of the ticking noise from my multiple exhaust leaks. The noise, coupled with some performance concerns (mainly mileage related) have finally driven me to replace the exhaust manifold. I have a 2002 Olds Bravada - so it's the first design of the manifold and downpipe. I've...

Pay particular attention to the difficulties had during the removal process.

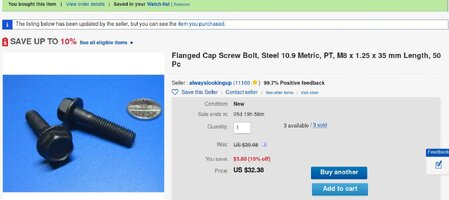

For anyone looking to Upgrade from the Fully Threaded Dorman shorter replacement M8 X 1.25 X 30MM Exhaust Manifold Bolts to the LONGER ones required for the Dorman version of the GM 4.2L Exhaust Manifold that has the 5MM THICKER Flange ... eBay has the M8 X1.25X 35MM @ 50 Count Pack for $32.38 that breaks out at right around $00.65 Per Bolt:

I have other applications that require using these identical bolts... so having the others as Extras on hand ...is never a bad idea. What is NICE about these 10.9 Hard Flanged Cap Screw Fasteners is that they are designed with a smooth portion, just under the Flanged Area with Partial Threads (PT) further down their lengths.

Usually, the GM OEM Bolts are FULLY Threaded in these same locations where Rust, Corrosion and a Loss of Bolt Strength over time can more easily attack the OEM version ...inviting them to Snap OFF all along the Exhaust Manifold Flange Line:

Here are some images to bear out these differences:

...and FWIW... THESE Fasteners have been "Made In The USA"

Electronics, Cars, Fashion, Collectibles & More | eBay

Buy & sell electronics, cars, clothes, collectibles & more on eBay, the world's online marketplace. Top brands, low prices & free shipping on many items.

rover.ebay.com

I have other applications that require using these identical bolts... so having the others as Extras on hand ...is never a bad idea. What is NICE about these 10.9 Hard Flanged Cap Screw Fasteners is that they are designed with a smooth portion, just under the Flanged Area with Partial Threads (PT) further down their lengths.

Usually, the GM OEM Bolts are FULLY Threaded in these same locations where Rust, Corrosion and a Loss of Bolt Strength over time can more easily attack the OEM version ...inviting them to Snap OFF all along the Exhaust Manifold Flange Line:

Here are some images to bear out these differences:

...and FWIW... THESE Fasteners have been "Made In The USA"

Last edited:

What is the part # for the up graded manifold, looking to purchase

Is this the thicker one? Thanks Greg

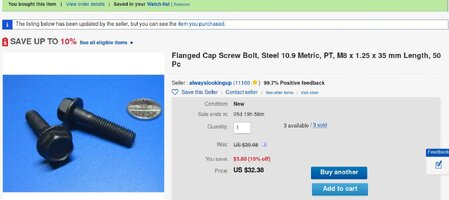

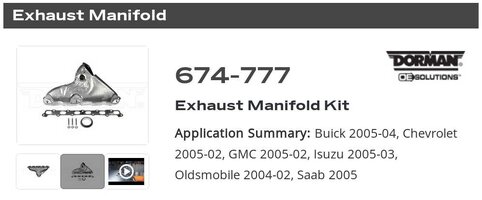

| DORMAN 674-990 Exhaust Manifold |

Look at the very bottom of the page for Dorman's choice of Fasteners... Just Click on both Fastener Images to get all of "The Dope":

www.dormanproducts.com

www.dormanproducts.com

Since you are dealing with the 2006 > Years... You'll have to 'Mike' the Thickness of the Flanges on the Dorman Part # 674-990 Exhaust Manifold yourself.

The Dorman Part # 674-777 flavor made for the 2002-2005 GM Atlas 4.2L Engines DO 'Mike' out to have 5mm THICKER FLANGES. So this makes for the requirement of using the Longer 35mm long After-Market 10.9 M8 X 1.25 X 35mm Fasteners a necessity ...Otherwise... Not enough length of the Bolts will thread as far down inside the Aluminum Engine Head Exhaust Manifold Flange as possible ... but this may NOT be the case with the Dorman Part# 674-999.

So... perform the necessary 'Due Diligence' needed here on your own to get this right, or you might wind up Damaging the Exhaust Manifold AND/OR causing Damage the Thread-Lines nested inside of the Threaded Holes adjacent the (6) Exhaust Ports of your 2006 Aluminum Engine Head.

DO NOT EXCEED 15 FOOT POUNDS OF TORQUE WHEN TIGHTENING DOWN THESE FASTENERS, REGARDLESS OF LENGTH.

I

Dorman Products - 674-990

Exhaust Manifold Kit - Includes Required Gaskets And Hardware

Since you are dealing with the 2006 > Years... You'll have to 'Mike' the Thickness of the Flanges on the Dorman Part # 674-990 Exhaust Manifold yourself.

The Dorman Part # 674-777 flavor made for the 2002-2005 GM Atlas 4.2L Engines DO 'Mike' out to have 5mm THICKER FLANGES. So this makes for the requirement of using the Longer 35mm long After-Market 10.9 M8 X 1.25 X 35mm Fasteners a necessity ...Otherwise... Not enough length of the Bolts will thread as far down inside the Aluminum Engine Head Exhaust Manifold Flange as possible ... but this may NOT be the case with the Dorman Part# 674-999.

So... perform the necessary 'Due Diligence' needed here on your own to get this right, or you might wind up Damaging the Exhaust Manifold AND/OR causing Damage the Thread-Lines nested inside of the Threaded Holes adjacent the (6) Exhaust Ports of your 2006 Aluminum Engine Head.

DO NOT EXCEED 15 FOOT POUNDS OF TORQUE WHEN TIGHTENING DOWN THESE FASTENERS, REGARDLESS OF LENGTH.

I

Mooseman

Moderator

I got a no-name "improved" manifold from eBay for my '02 way-back in 2011 when I replaced the engine (both the original and the one on the replacement engine were cracked). It lasted until I scrapped it in 2017 and kept it as a spare.

The flanges aren't the problem, it's at the Y's. I remember hearing of those still on an extended warranty getting them replaced by the dealer and still cracking. 08-09 had the least instances of cracking but are a totally different design that would require you replace the front pipe and extend the O2 sensor wires as it was relocated to the pipe.

Another option is a header but that's an expensive one:

The flanges aren't the problem, it's at the Y's. I remember hearing of those still on an extended warranty getting them replaced by the dealer and still cracking. 08-09 had the least instances of cracking but are a totally different design that would require you replace the front pipe and extend the O2 sensor wires as it was relocated to the pipe.

Another option is a header but that's an expensive one:

Electronics, Cars, Fashion, Collectibles & More | eBay

Buy & sell electronics, cars, clothes, collectibles & more on eBay, the world's online marketplace. Top brands, low prices & free shipping on many items.

rover.ebay.com