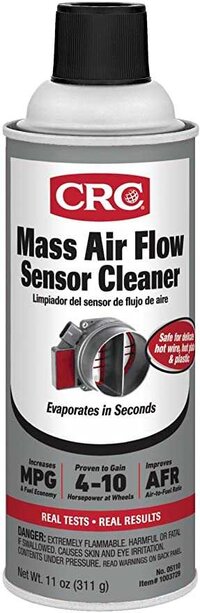

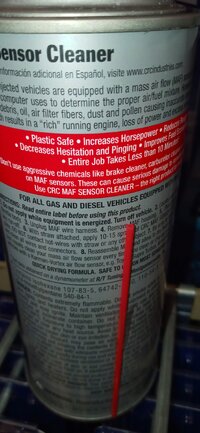

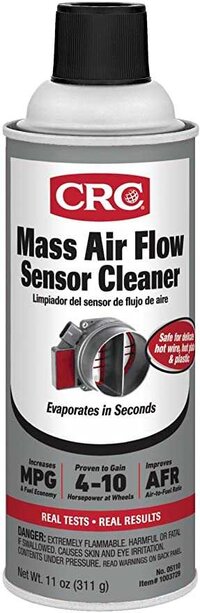

THIS is the only recommended cleaning solvent specifically made by

CRC for cleaning that delicate MAF Sensor "Bulb". Recently, I saw

a video of ScannerDanner working on a Late Model GM Silverado at his Brother's Garage

manually cleaning the MAF Sensor "Bulb" with a very small brush while also using only the

CRC MAF Spray Solvent ...and it worked great...

But he was being VERY careful with its application though:

Buy CRC 05110 Mass Air Flow Sensor Cleaner - 11 Wt Oz.: Collision Repair Sets - Amazon.com ✓ FREE DELIVERY possible on eligible purchases

www.amazon.com

Here he is explaining his Abbreviated, Universal "

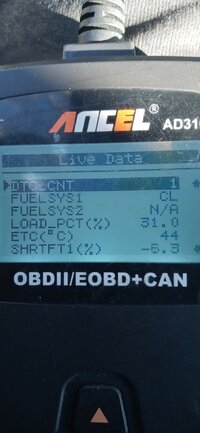

How to Diagnose a P0171 involving cleaning issues with the MAF Sensors":