- Jan 29, 2012

- 268

I found that my air bags were not inflating when my compressor ran. I confirmed that the compressor still had pressure by using the aux hose and running using the switch to activate it.

Further research (thanks GMTNation) showed that the likely culprit was the check valve in the system no longer functioning, to which there is a rebuild kit. Part # 1518-3676 It's about $35. I found a description on another site about a method to refurbish the existing parts, so I thought I'd give that a go. So far so good, so here's my procedure.

Pull the fuse for the air suspension system. Mine was #1 under the hood.

Jack up the rear end and remove the passenger tire.

Two 13mm bolts hold the compressor to the frame rail. You need to lift up to remove it, it's got a couple of tabs that lock in to the top of the frame rail.

Remove the two hoses that connect to the left and right air bags - can't remember the wrench size but it was small. You shouldn't need to remove the other connections - you should have this by now.

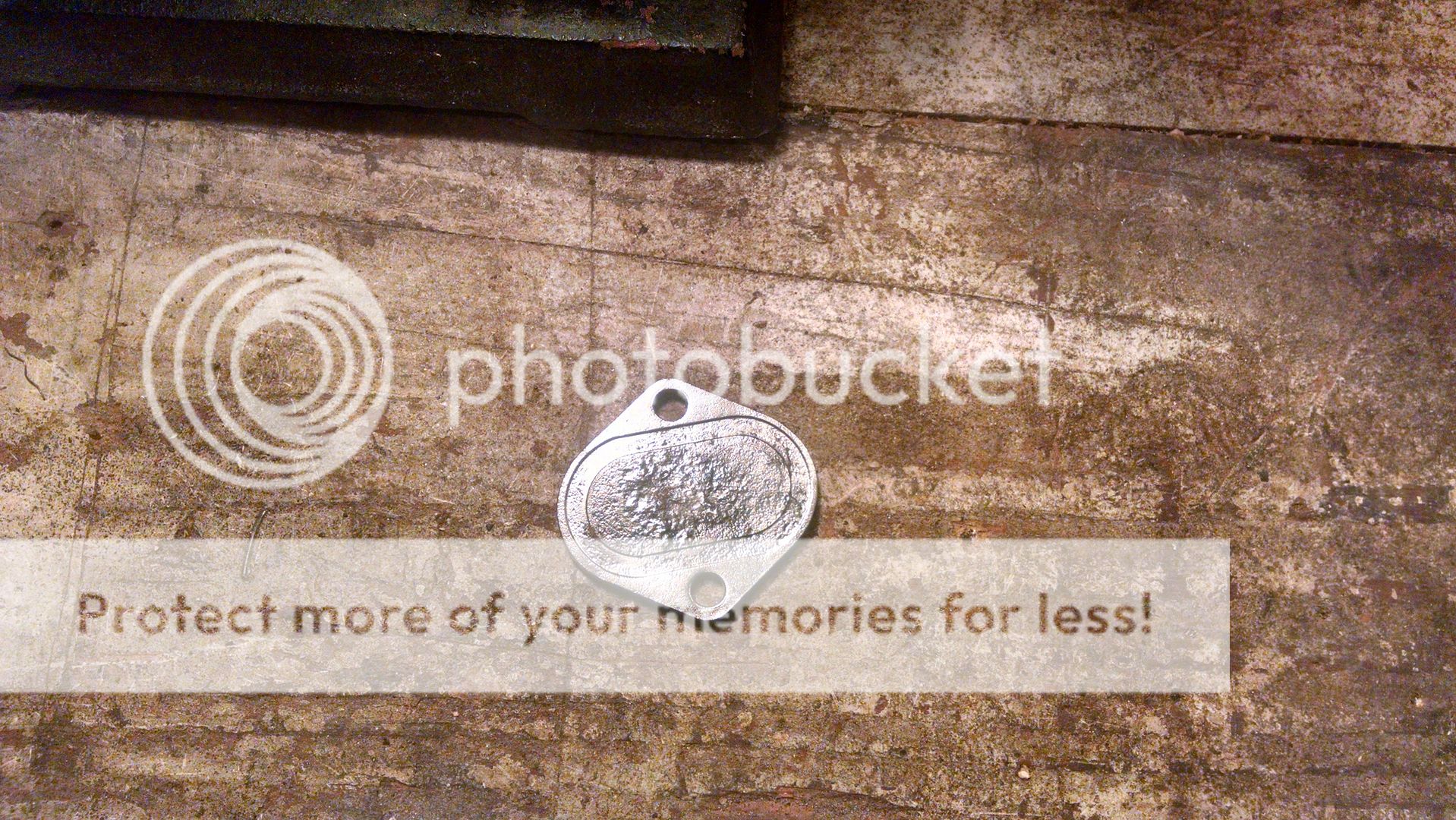

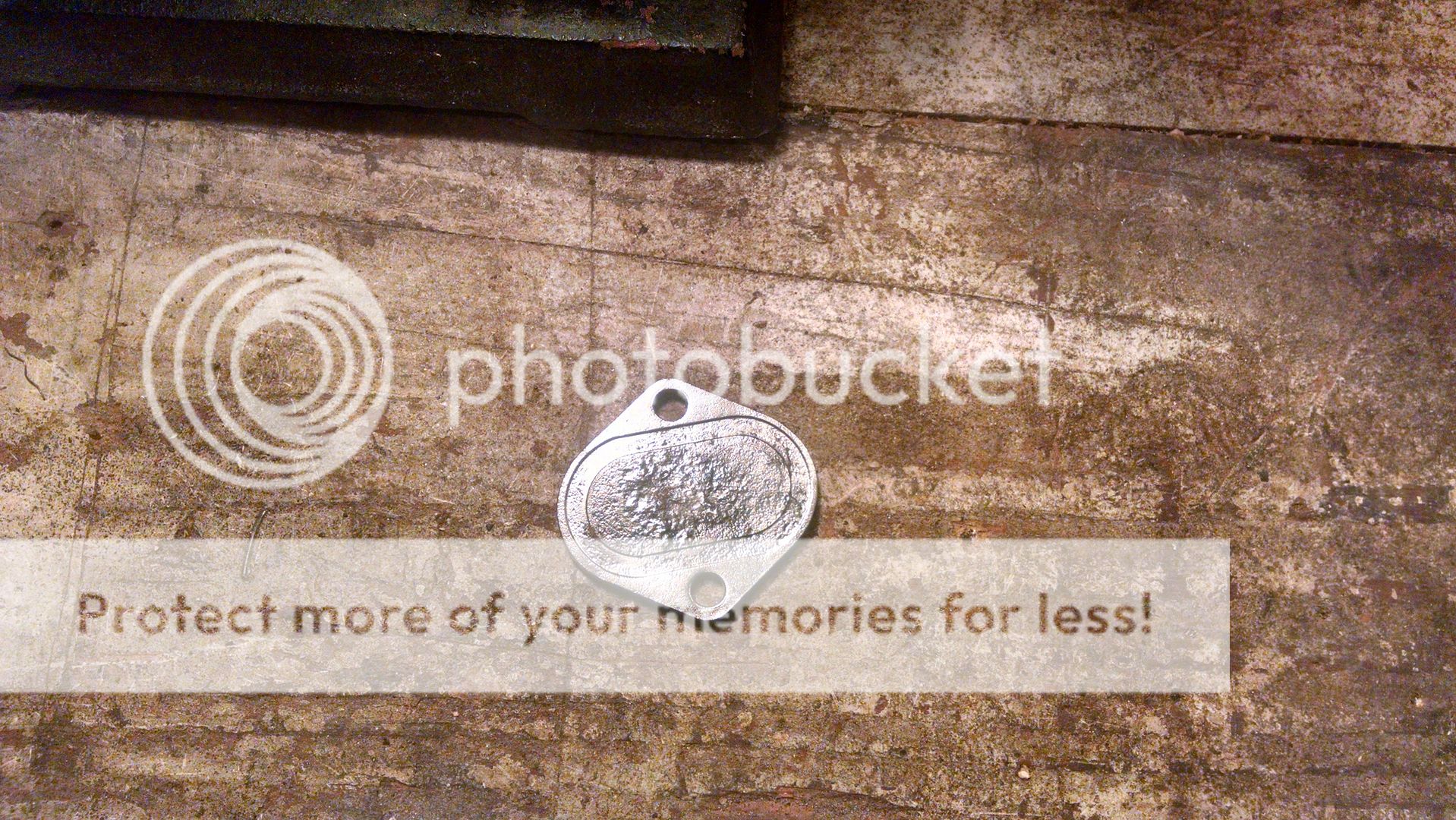

The really rusty access panel on the outside of the pump takes a Torx 25 bit to open up - 2 screws. I took brake cleaner and sprayed it down before opening it up - try to keep dirt out. You'll find these parts inside.

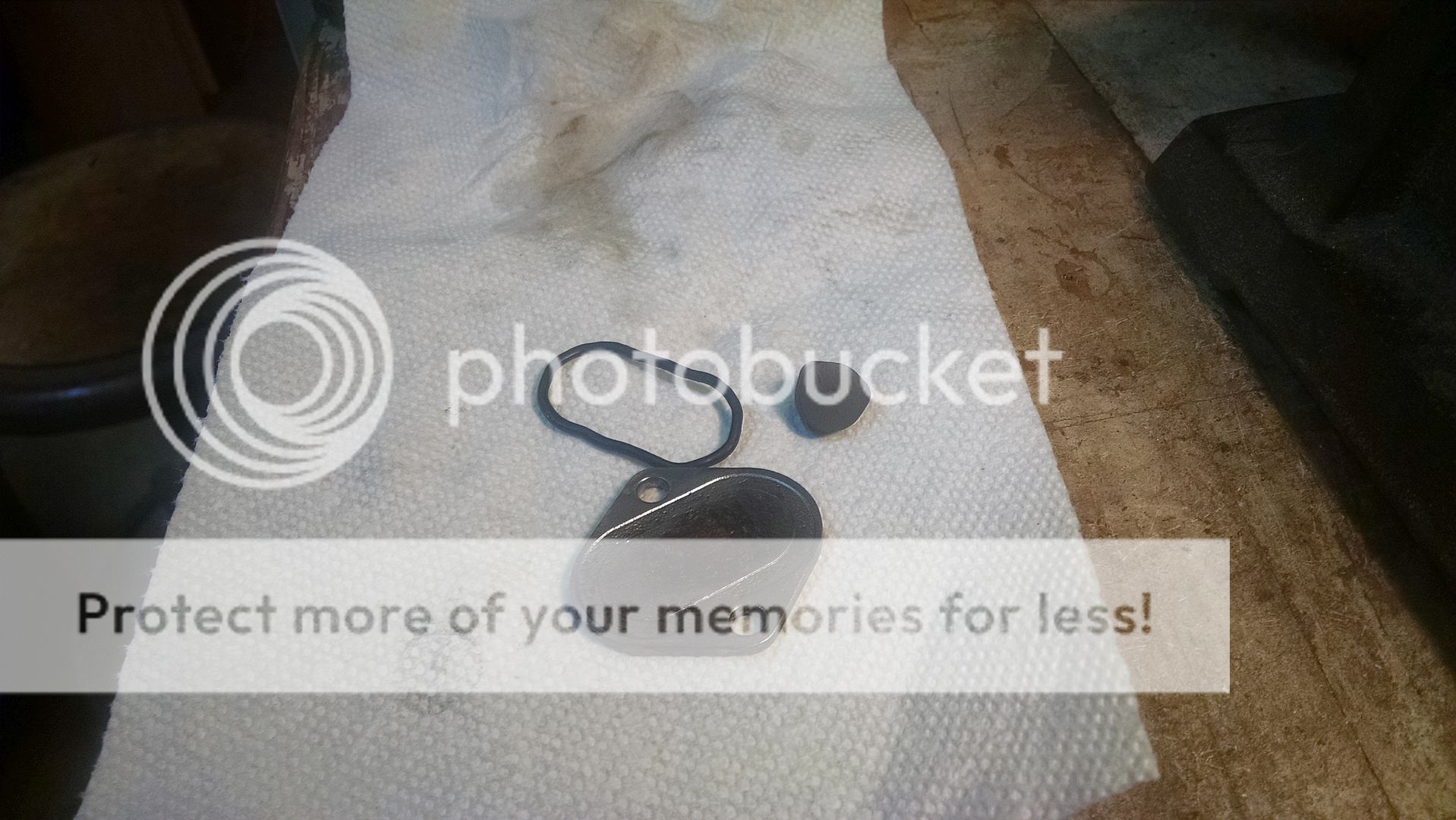

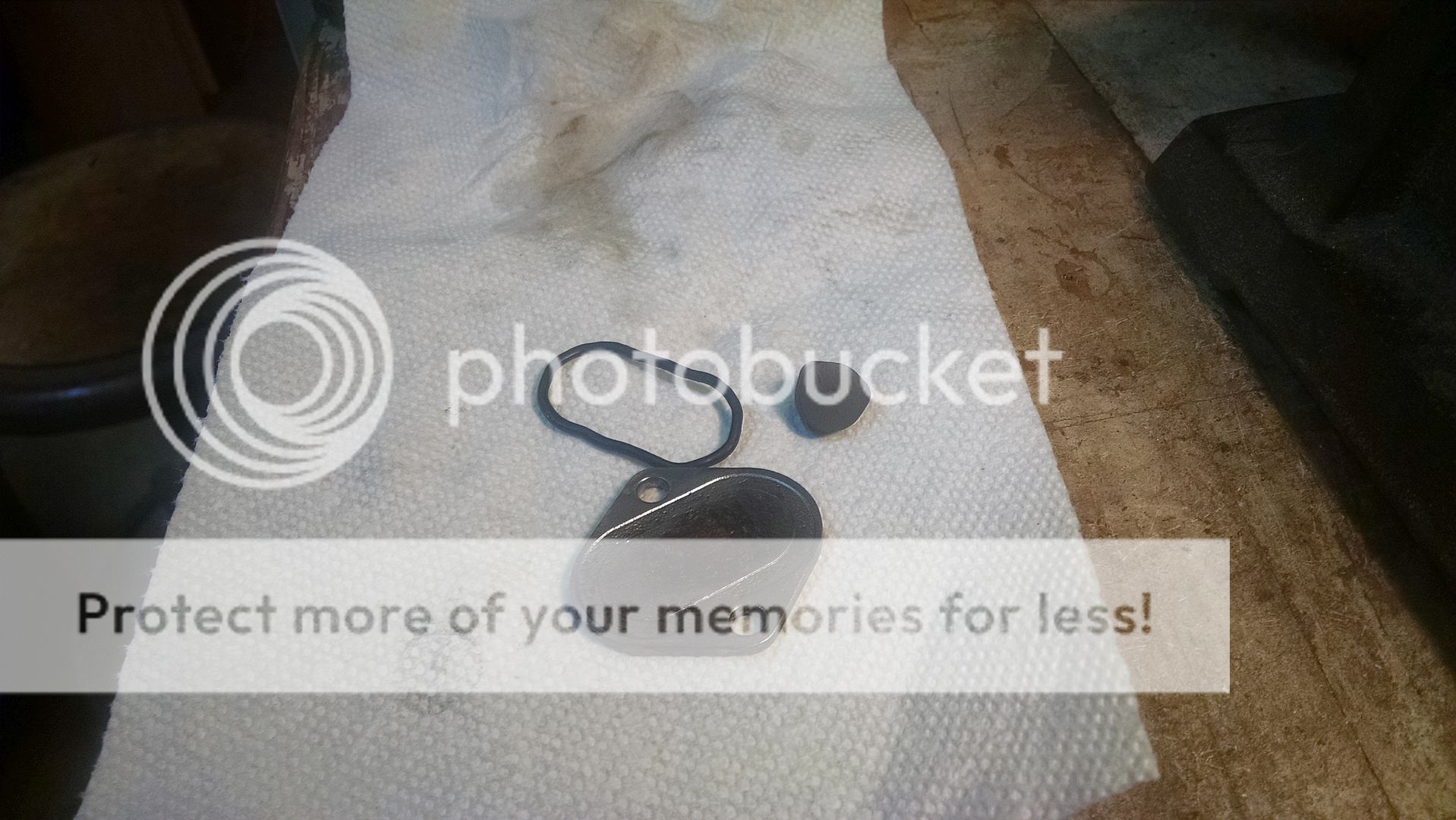

The imprinted circle in the rubber piece is the culprit. I used 400 grit sand paper on a flat surface to rub it back to a smooth clean surface. I also used a wire wheel on the access panel to get it clean, the inner surface in particular.

I then used silicone spray to clean everything up, the gasket as well. You can see that now the rubber piece is smooth, and the gasket has resumed a better shape.

I used a bit of silicone grease on the surface of the rubber piece and the gasket before reassembling. I also used a wire brush gently on the pump body to try and clean off at least the worst of the corrosion. I gave it a good shot with brake cleaner and then the silicone spray to clean out any dirt that may have made its way inside. Here's the before picture, no after.

I put it back together, put the fuse in and fired it up. The pump ran for about 20 seconds with no change, just like it had been before. I think to myself this isn't a good thing, because now I've let ALL the air out of the bags and I'm on the bump stops. I shut it off and fired again, this time it ran for longer and started to lift the back end. I stopped it after a bit and let the pump cool before starting again and letting it finish. I think the first time it had to fill the bags from zero, and like before sensed no change and shut off. The second time enough pressure was built up that it started to move and therefore finished the job.

So far I've run it a few times and it's run at startup for a few minutes each time. I'm hoping I got the air lines back in tight, if I think it's leaking it won't take too long to pop it off and snug those down. I didn't want to overdue it.

Further research (thanks GMTNation) showed that the likely culprit was the check valve in the system no longer functioning, to which there is a rebuild kit. Part # 1518-3676 It's about $35. I found a description on another site about a method to refurbish the existing parts, so I thought I'd give that a go. So far so good, so here's my procedure.

Pull the fuse for the air suspension system. Mine was #1 under the hood.

Jack up the rear end and remove the passenger tire.

Two 13mm bolts hold the compressor to the frame rail. You need to lift up to remove it, it's got a couple of tabs that lock in to the top of the frame rail.

Remove the two hoses that connect to the left and right air bags - can't remember the wrench size but it was small. You shouldn't need to remove the other connections - you should have this by now.

The really rusty access panel on the outside of the pump takes a Torx 25 bit to open up - 2 screws. I took brake cleaner and sprayed it down before opening it up - try to keep dirt out. You'll find these parts inside.

The imprinted circle in the rubber piece is the culprit. I used 400 grit sand paper on a flat surface to rub it back to a smooth clean surface. I also used a wire wheel on the access panel to get it clean, the inner surface in particular.

I then used silicone spray to clean everything up, the gasket as well. You can see that now the rubber piece is smooth, and the gasket has resumed a better shape.

I used a bit of silicone grease on the surface of the rubber piece and the gasket before reassembling. I also used a wire brush gently on the pump body to try and clean off at least the worst of the corrosion. I gave it a good shot with brake cleaner and then the silicone spray to clean out any dirt that may have made its way inside. Here's the before picture, no after.

I put it back together, put the fuse in and fired it up. The pump ran for about 20 seconds with no change, just like it had been before. I think to myself this isn't a good thing, because now I've let ALL the air out of the bags and I'm on the bump stops. I shut it off and fired again, this time it ran for longer and started to lift the back end. I stopped it after a bit and let the pump cool before starting again and letting it finish. I think the first time it had to fill the bags from zero, and like before sensed no change and shut off. The second time enough pressure was built up that it started to move and therefore finished the job.

So far I've run it a few times and it's run at startup for a few minutes each time. I'm hoping I got the air lines back in tight, if I think it's leaking it won't take too long to pop it off and snug those down. I didn't want to overdue it.