With your Motor approaching the

300,000 Mile Mark (Which deserves "Much Kudos" for The Owner sustaining that platform for such a long time) it is very likely that you have an excessive amount of

Black Carbon and Greasy Gas Gum built up around the Valve Seats. Remember ...there are Four Valves Per Cylinder here. These are some of the issues worth investigating along with suggested

ACTIONS to take in response:

(1)

Excessive Carbon Build Up can obstruct the Closing Off and Sealing Up of the Valves sufficiently to reduce an effective Compression Seal and manifest here as a Loss of Power.

(2)

Excessive Carbon Build Up in the Upper Cylinder and Piston Heads can

INCREASE Compression inviting Pre-Ignition Events and can cause P0300 Mis-Fire Codes once the "Quench" level is increased enough at just before TDC to cause the Fuel/Air Combo to ignite at the wrong time.

(3)

Excessive Gas Gum and Carbon Build Up can cause the Two Compression Rings on and around each Piston to literally get them GLUED inside of the Lands and Grooves such that due to their "Low Tension"...they cannot rebound enough to maintain decent Compression at or near TDC. This results in a Power Loss from Poor F/A Combustion will Result. Piston Slap and Engine Oil Contamination from Fuel are also increased in this condition.

ACTION: Check the Engine Oil Dip-Stick for an excessive odor of Gasoline.

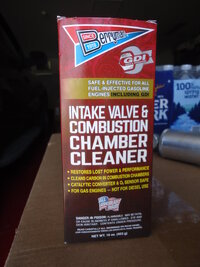

ACTION: Using

ACDelco Top Engine Cleaner as described in these Threads can help with above Items 1,2 & 3:

DuckDuckGo. Privacy, Simplified.

duckduckgo.com

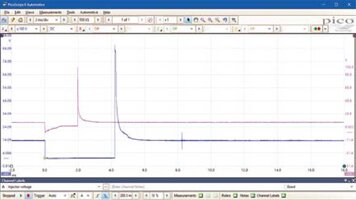

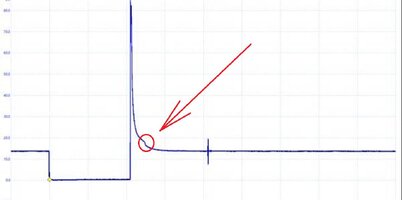

ACTION: Perform a Cylinder Balance Test and Relative Compression Test.

(4) A

Clogged CAT... can present with

Too Much Back Pressure and prevent the proper exhalation of burned F/A By-Products. Take note that most of any Excess Fuel and Engine Oil residue that escapes the Cylinders through the Exhaust and into the CAT will never pass through the Tail Pipe or leave any Tell-Tale Signs of a problem. The Excess Fuel in the Exhaust of an unregulated engine will quickly destroy a CAT and a Blinking DASH Light means

"FIX ME SOONEST ...OR ELSE".

ACTION: Perform a Back Pressure Test. This will reveal if this is a problem.

ACTION: Remove the Upstream O2 Sensor and drive the vehicle around for a short distance to see if the Engine Power substantially improves

.

(5) A

Loose Intake Manifold can be an unusual source for the P0300 Codes due to allowing unmetered Air to by-pass the ability of the PCM to use the other F/A Sensors to figure out precisely how much Fuel to deliver to each Cylinder as an Atomized Spray.

ACTION: This one is unlikely if you used NEW "O" Ring Style Figure (8) IM Gaskets and tightened down the IM with a mere 89 Inch Pounds of Force. Hopefully, none of the (10) 10mm IM Trapped Fasteners were broken off while you were replacing your Fuel Injectors as having P0300 Codes would become inevitable.