The VOP (Video Original Poster) here goes off on an unfortunate RANT while impugning the undeserving FelPro Company about his own mistaken actions of ending up installing the Wrong MLS Stainless Steel-Composite Head Gasket on top of some GM 4.2L Engine. The useful information he imparted for us though, is that this is a situation that CAN happen to any of us.

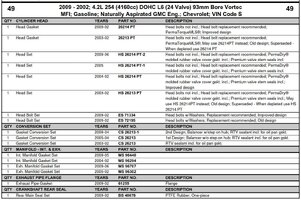

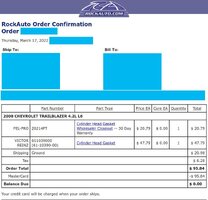

This is a Cautionary Tale for us to understand as much as possible about our own unique LL8 Motors beforehand and arrive at the Parts Counter with our Old Head Gasket 'In Hand' to compare very carefully with a Graduated Eye-Ball against the one we want to buy.

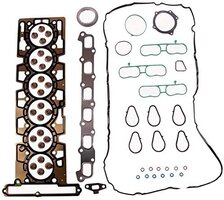

All MLS (Multi-Layered Stainless Steel) Gaskets are held together with Brass Rivets that are not Zero Elevation Items. If you wind up purchasing a Head Gasket that looks a lot like the Original OEM Head Gasket, but presents with any subtle differences in the positioning of these Brass Rivets at the WRONG LOCATIONS, then the Engine Head will not seal during the thread-in and torque up of the unique LL8 (17) Various types of Head Bolt Fasteners in the Set.

Be Thoughtful and Suspicious... Double Checking will Avoid Doing Double Duty, Having Double The "Head" Ache and Suffering Double The Expense:

This is a Cautionary Tale for us to understand as much as possible about our own unique LL8 Motors beforehand and arrive at the Parts Counter with our Old Head Gasket 'In Hand' to compare very carefully with a Graduated Eye-Ball against the one we want to buy.

All MLS (Multi-Layered Stainless Steel) Gaskets are held together with Brass Rivets that are not Zero Elevation Items. If you wind up purchasing a Head Gasket that looks a lot like the Original OEM Head Gasket, but presents with any subtle differences in the positioning of these Brass Rivets at the WRONG LOCATIONS, then the Engine Head will not seal during the thread-in and torque up of the unique LL8 (17) Various types of Head Bolt Fasteners in the Set.

Be Thoughtful and Suspicious... Double Checking will Avoid Doing Double Duty, Having Double The "Head" Ache and Suffering Double The Expense:

Last edited: