Figure it's about time to get all my projector retrofit stuff chronicled and documented. This will also be a way for you guys to keep me honest and motivated when I start slacking. (which tends to happen way too often.)

My first retrofit got started in the spring of 2013 and consisted of the following:

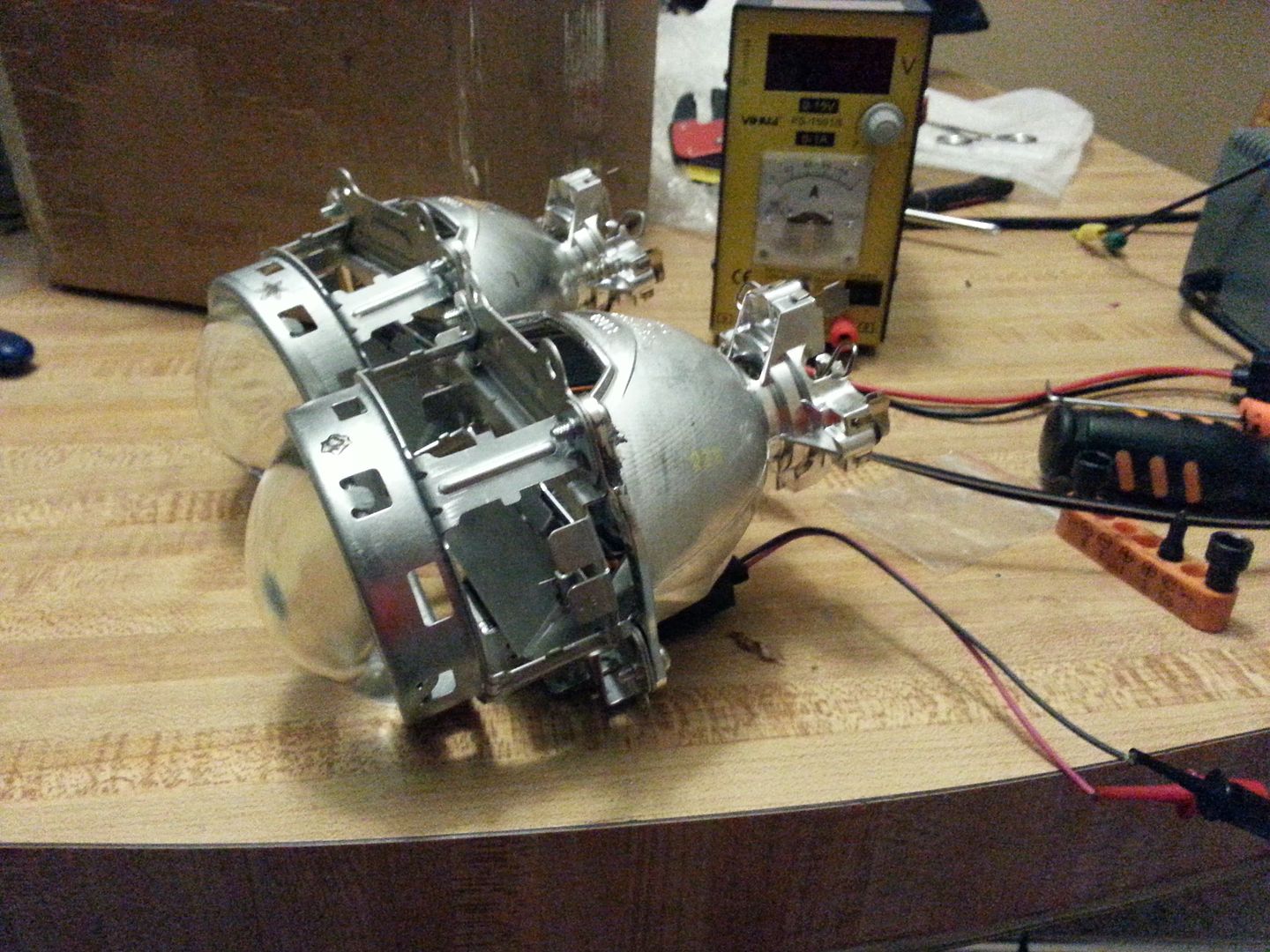

4 x Morimoto Mini D2S projectors

4 x Morimoto 3Five 35W ballasts

4 x Morimoto 3Five 6000K D2S bulbs

2 x Ocular shrouds

2 x Iris shrouds

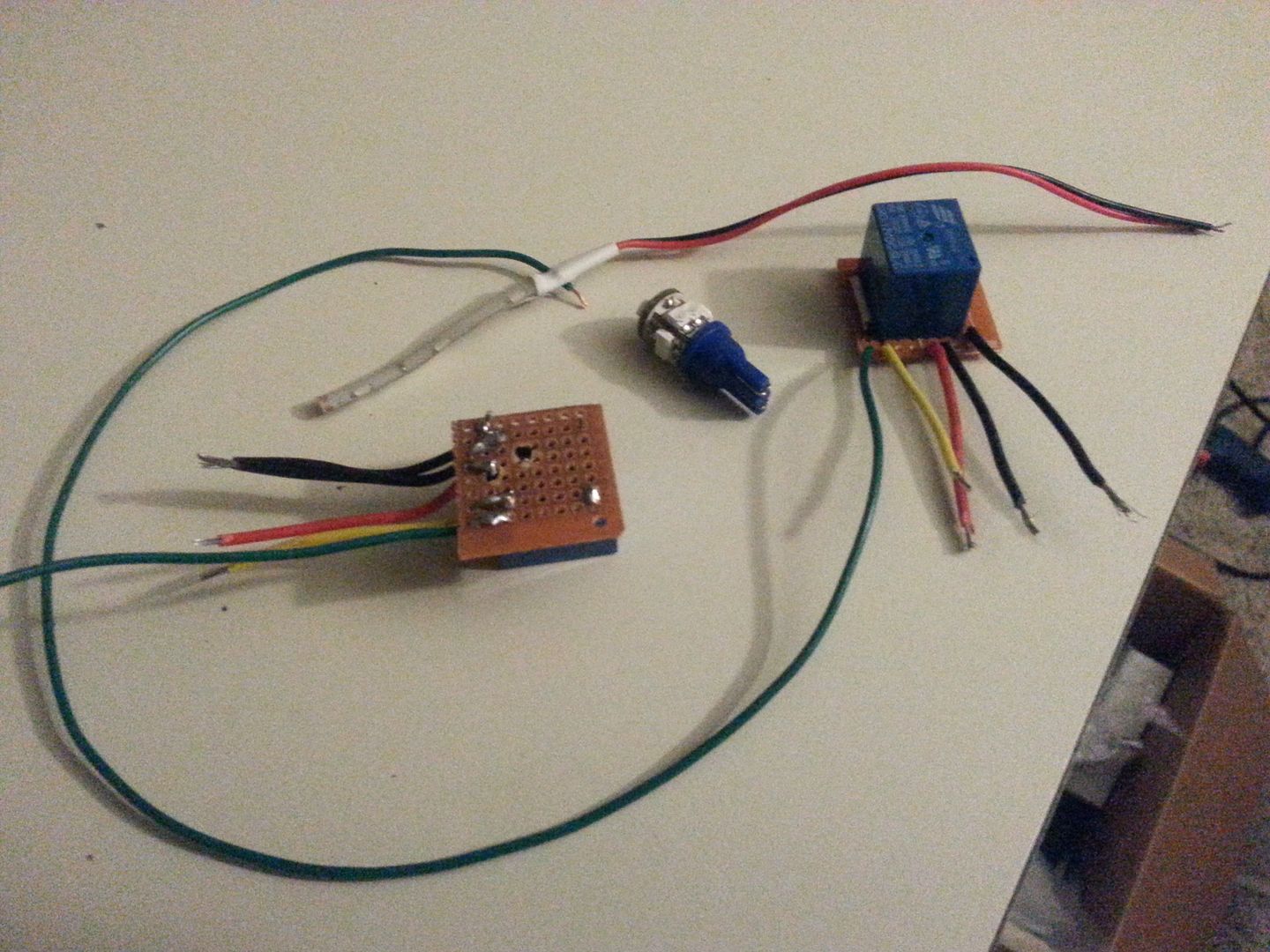

2 x 12" 5050 switchback strips

2 x 8" 5050 switchback strips

1 set of dark smoked OEM replica corner lenses

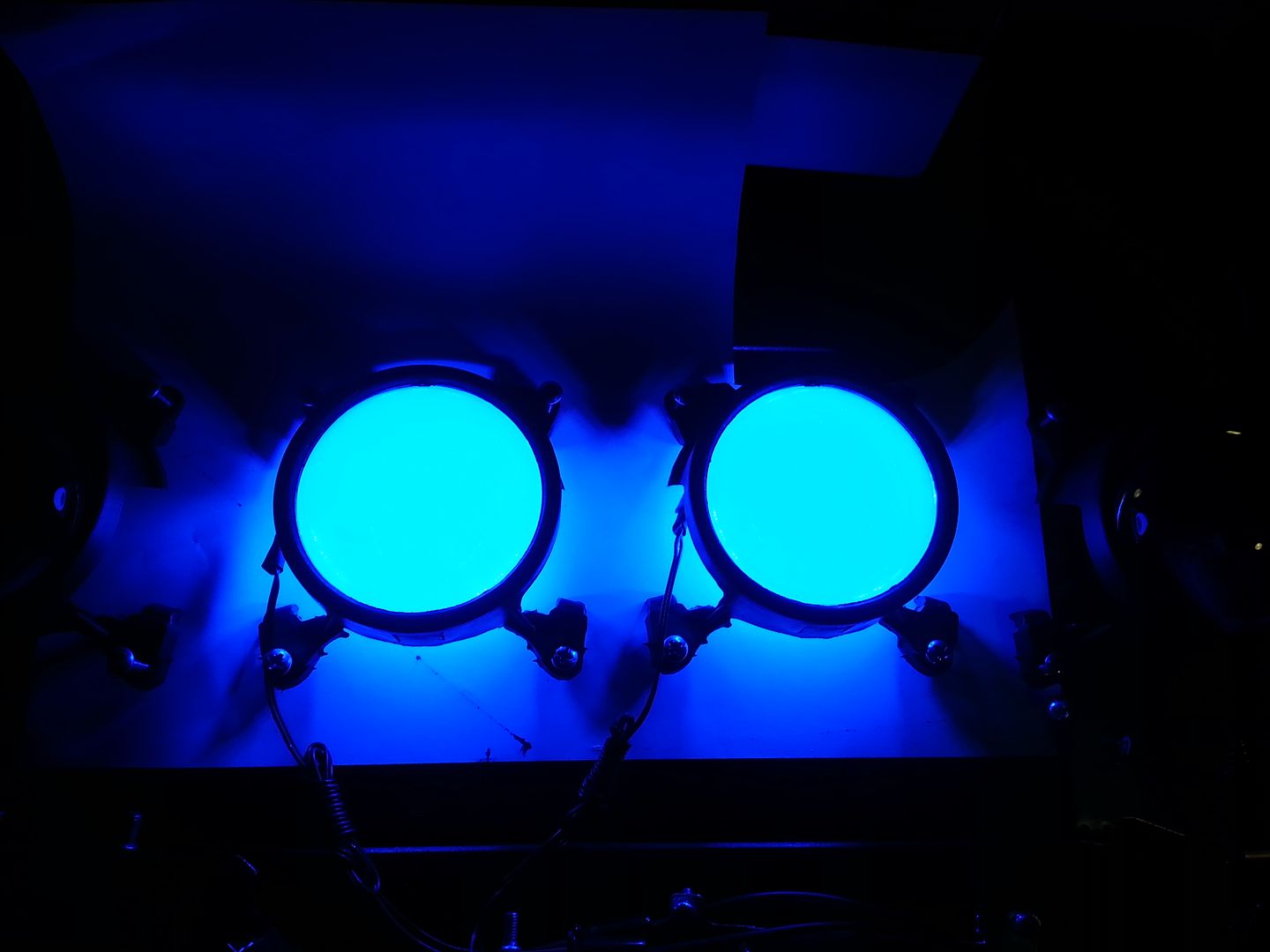

2 x 9" blue LED strips

2 x white Morimoto XB halos

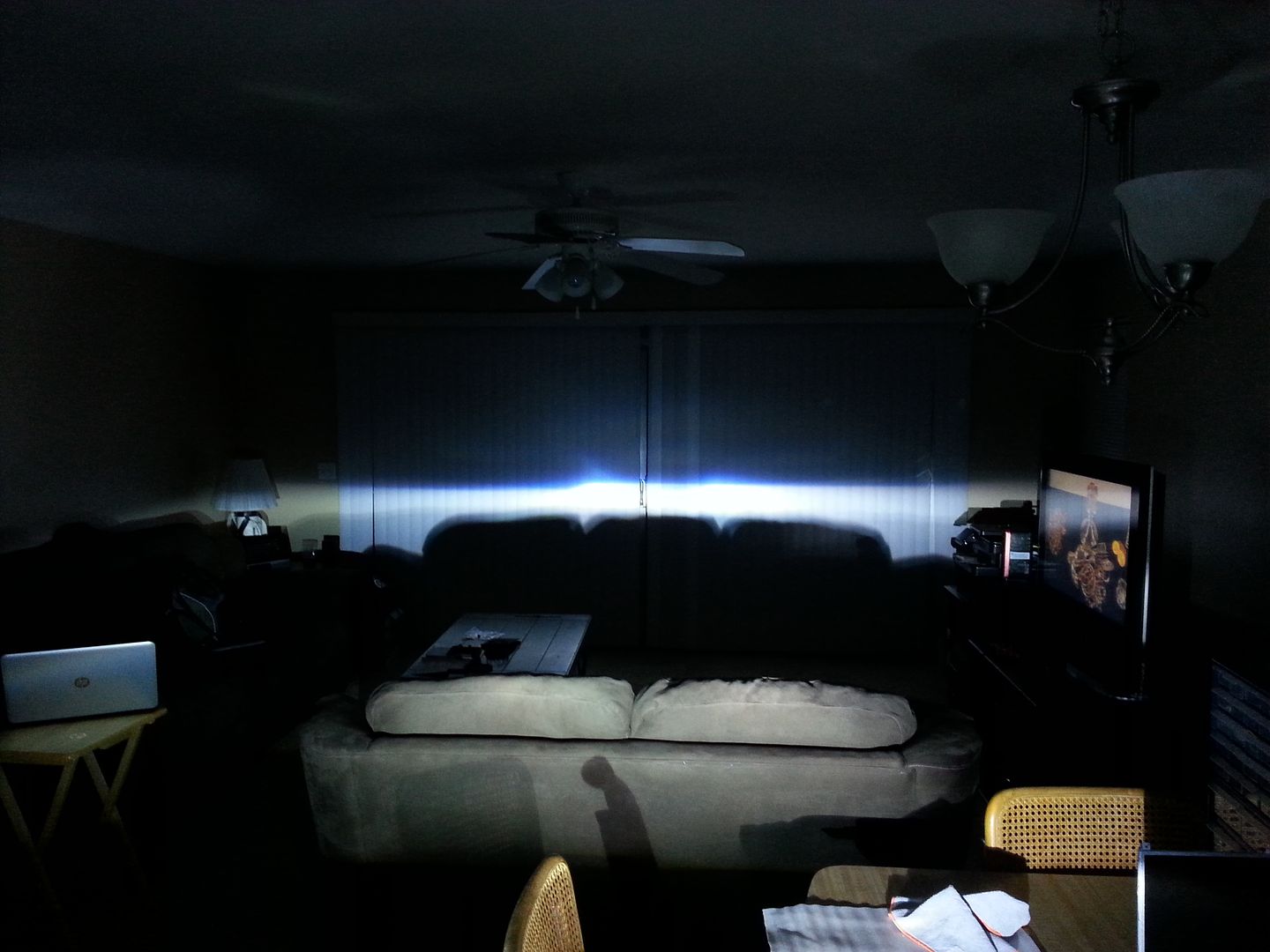

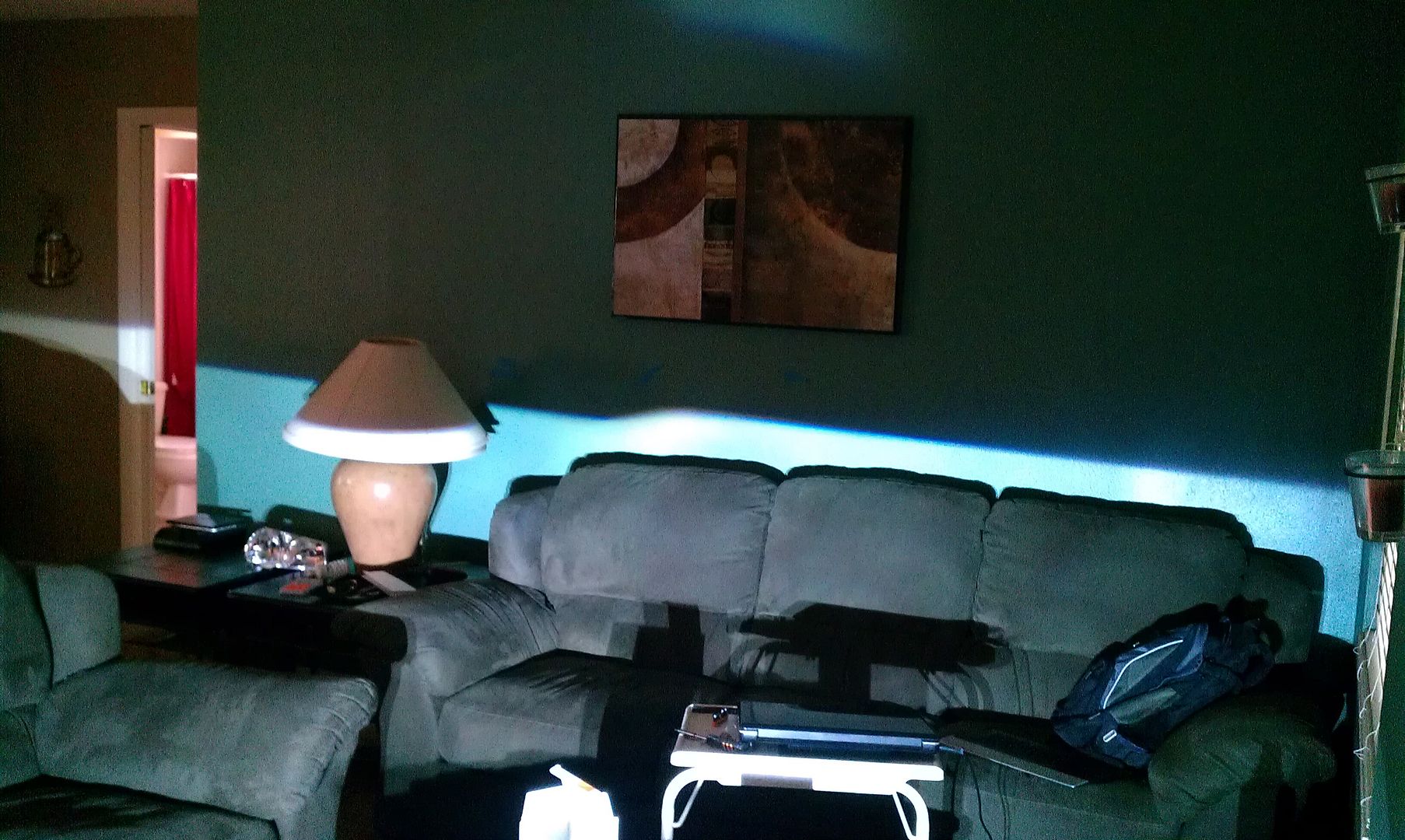

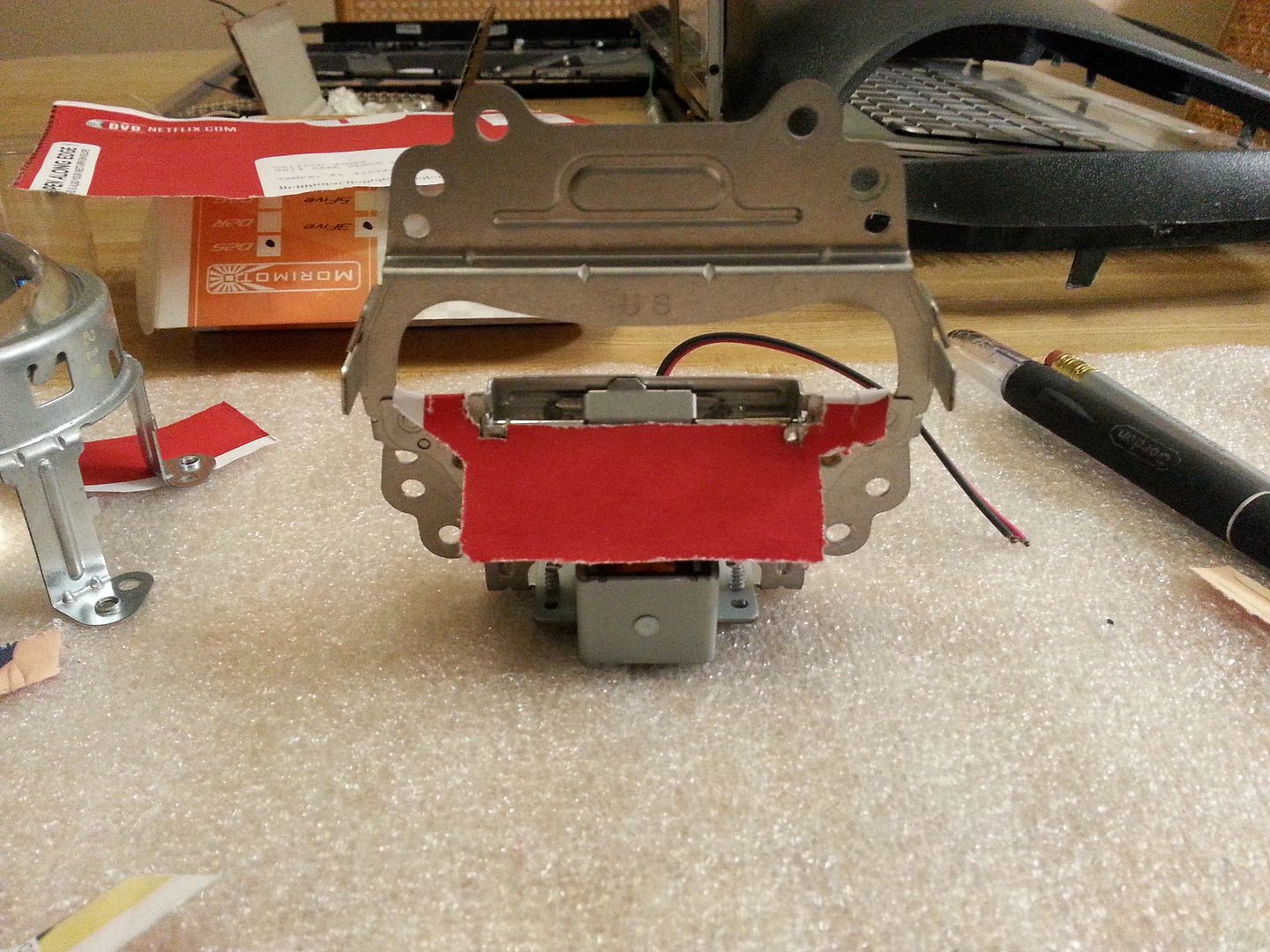

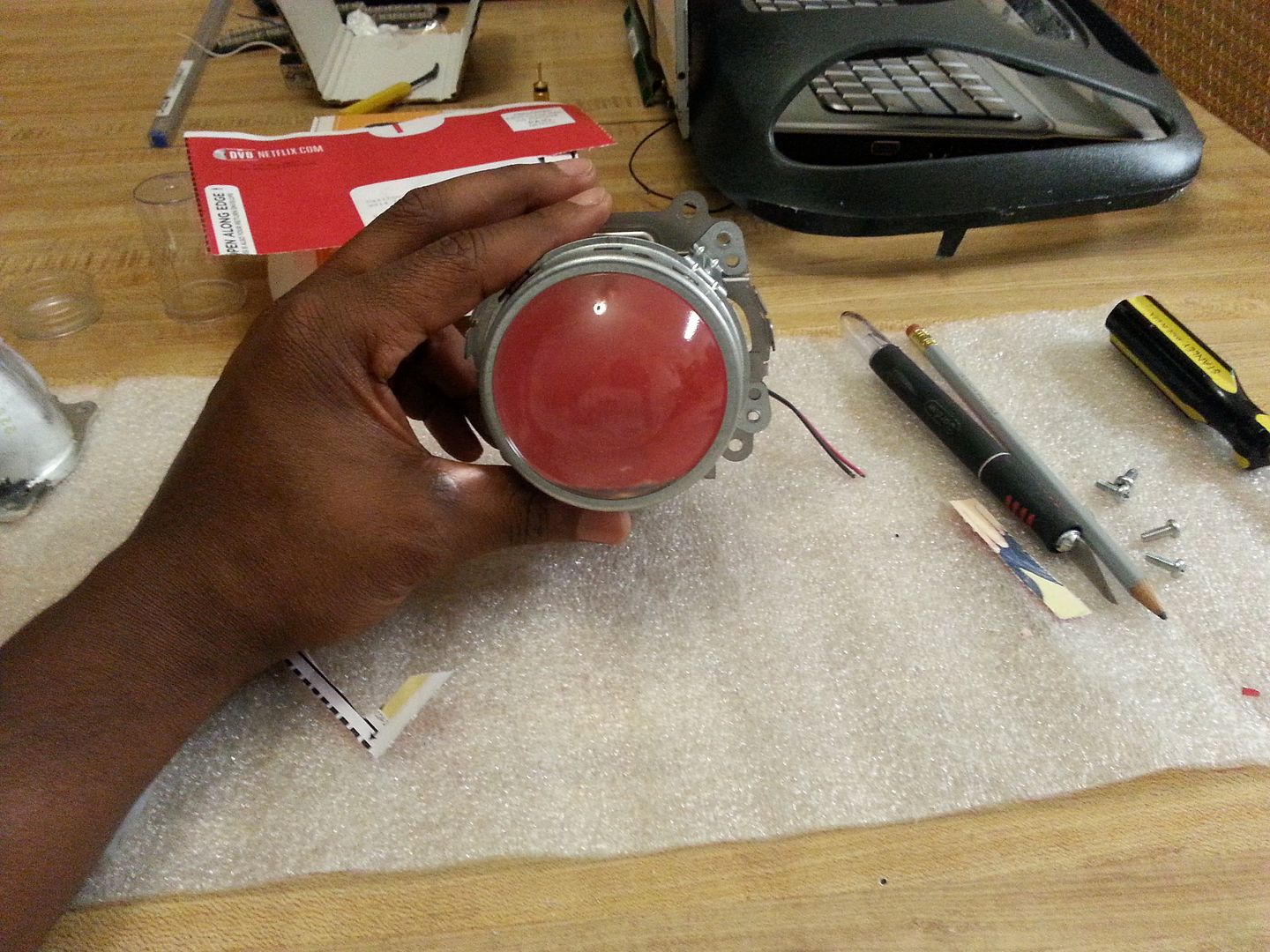

For the alignment process, I chose the indoor, living room wall method. Remove the reflector bowls from the headlight housings, clamped them to a bookshelf, powered up some halogen bulbs and marked the "cutoff and step" on the opposing wall with some painters tape. After marking where the reflector bowls were mounted on the shelf for later reference, it was time to get busy with the Dremel, and enlarge the bulb openings to fit the threaded shafts of the D2S projectors through.

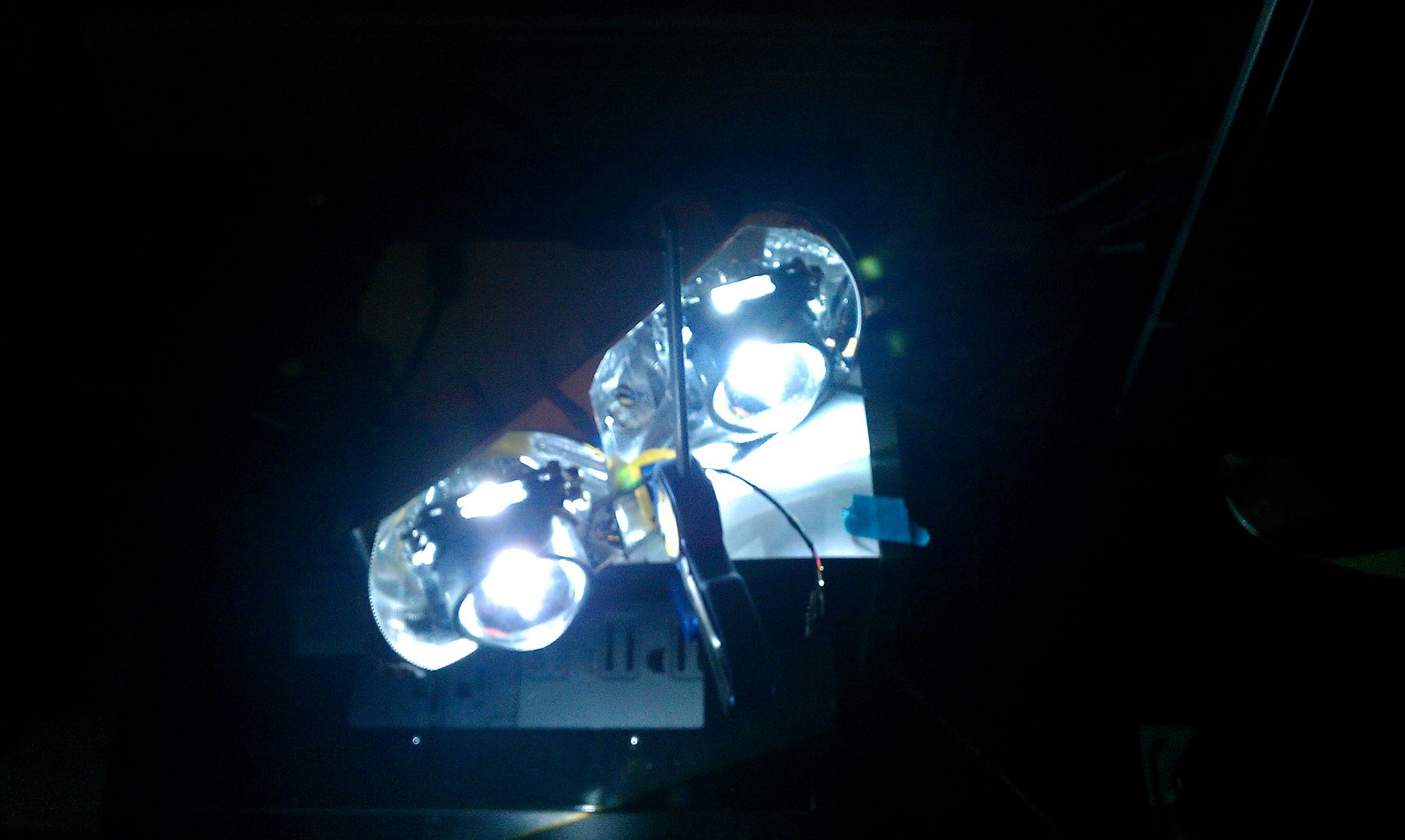

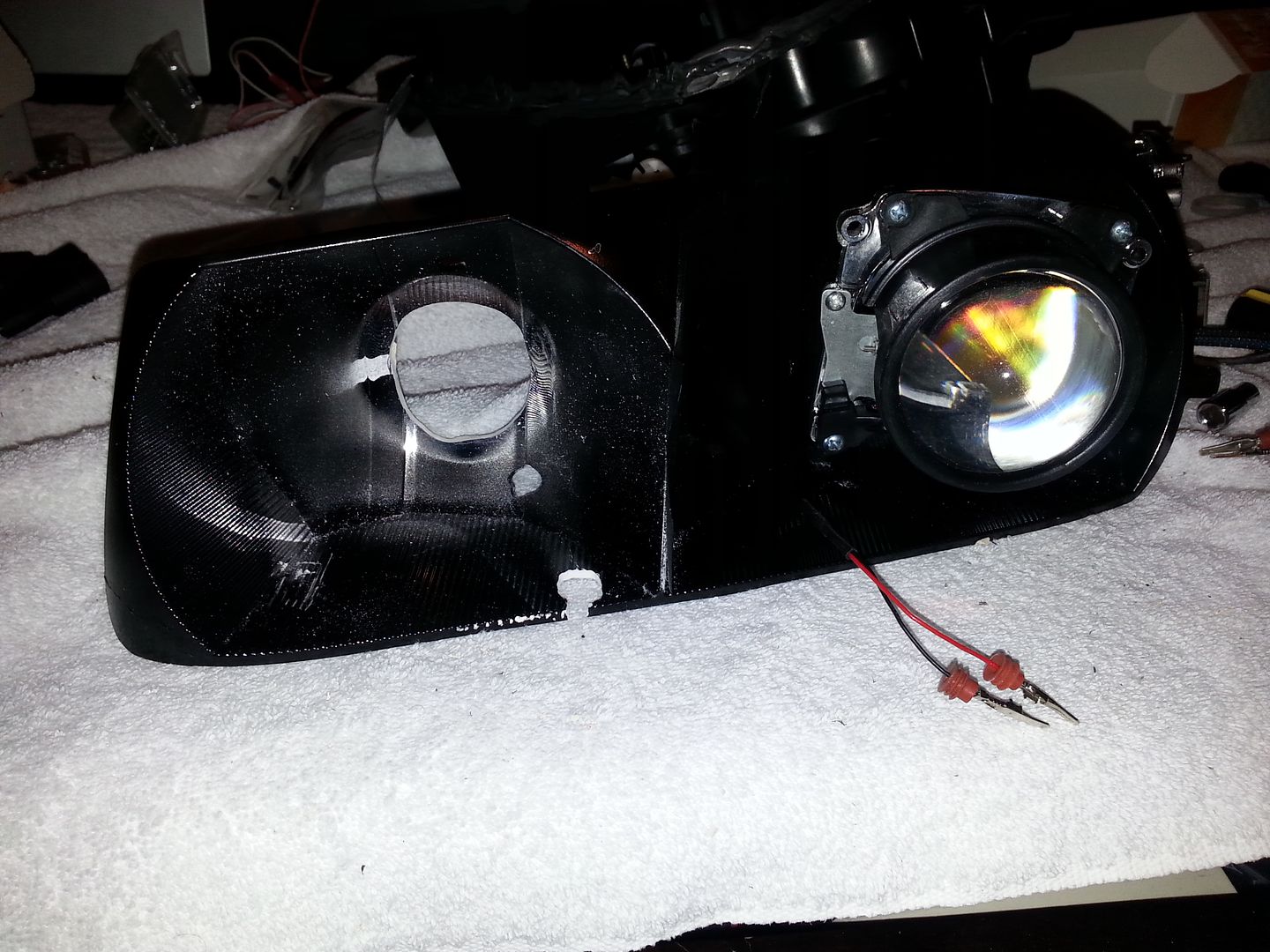

Note, the Morimoto Mini H1 projectors have a smaller shaft, and require minimal trimming if any. The D2S were considerable. Once the openings were large enough, it was time to install the projectors and make the necessary adjustments to align the beam patterns.

After removing them several times to shape the reflector bowl openings (the low beam projectors needed to be pointed higher, and the high beam projectors lower) I was able to get a good looking beam pattern on the wall.

My first retrofit got started in the spring of 2013 and consisted of the following:

4 x Morimoto Mini D2S projectors

4 x Morimoto 3Five 35W ballasts

4 x Morimoto 3Five 6000K D2S bulbs

2 x Ocular shrouds

2 x Iris shrouds

2 x 12" 5050 switchback strips

2 x 8" 5050 switchback strips

1 set of dark smoked OEM replica corner lenses

2 x 9" blue LED strips

2 x white Morimoto XB halos

For the alignment process, I chose the indoor, living room wall method. Remove the reflector bowls from the headlight housings, clamped them to a bookshelf, powered up some halogen bulbs and marked the "cutoff and step" on the opposing wall with some painters tape. After marking where the reflector bowls were mounted on the shelf for later reference, it was time to get busy with the Dremel, and enlarge the bulb openings to fit the threaded shafts of the D2S projectors through.

Note, the Morimoto Mini H1 projectors have a smaller shaft, and require minimal trimming if any. The D2S were considerable. Once the openings were large enough, it was time to install the projectors and make the necessary adjustments to align the beam patterns.

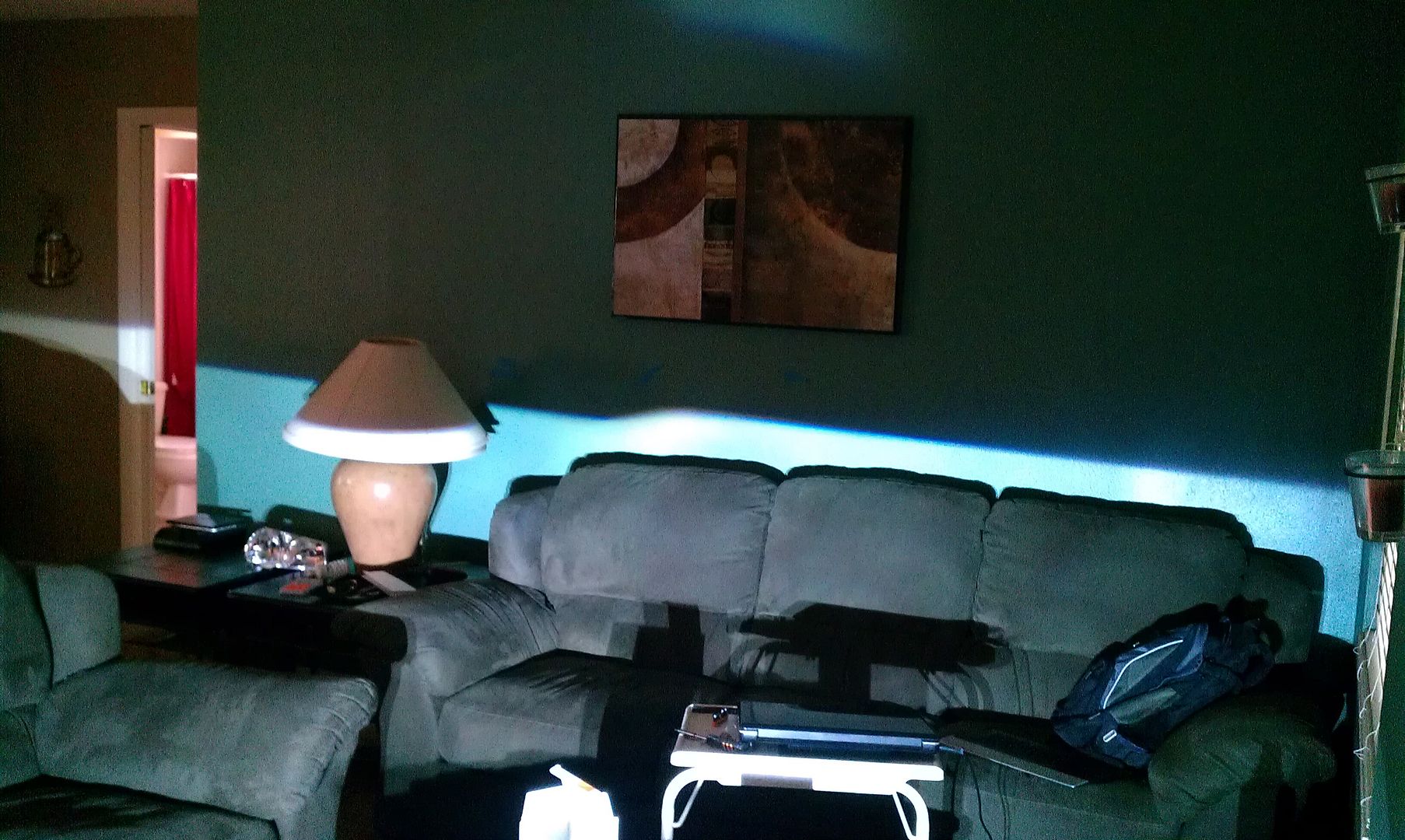

After removing them several times to shape the reflector bowl openings (the low beam projectors needed to be pointed higher, and the high beam projectors lower) I was able to get a good looking beam pattern on the wall.

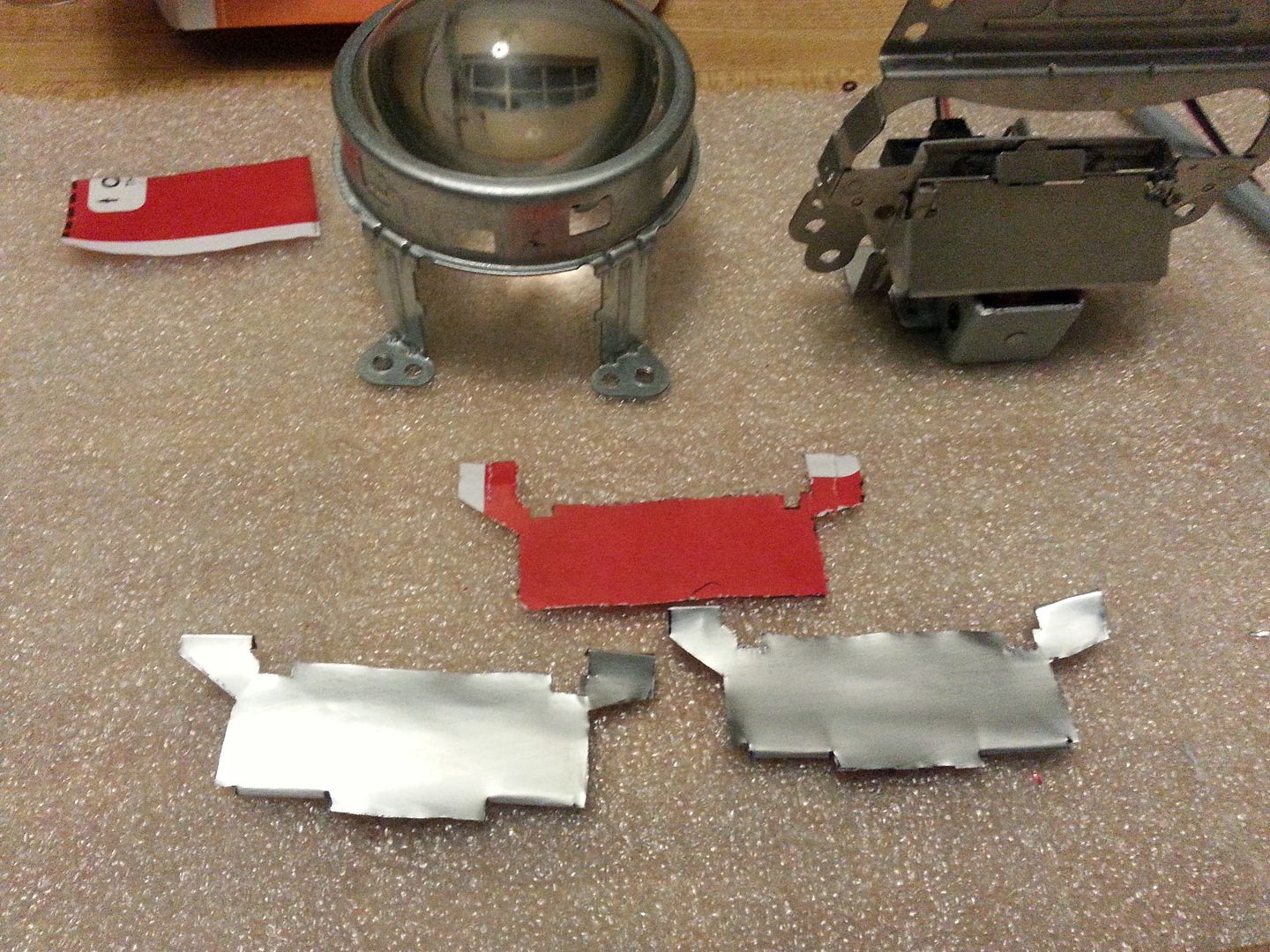

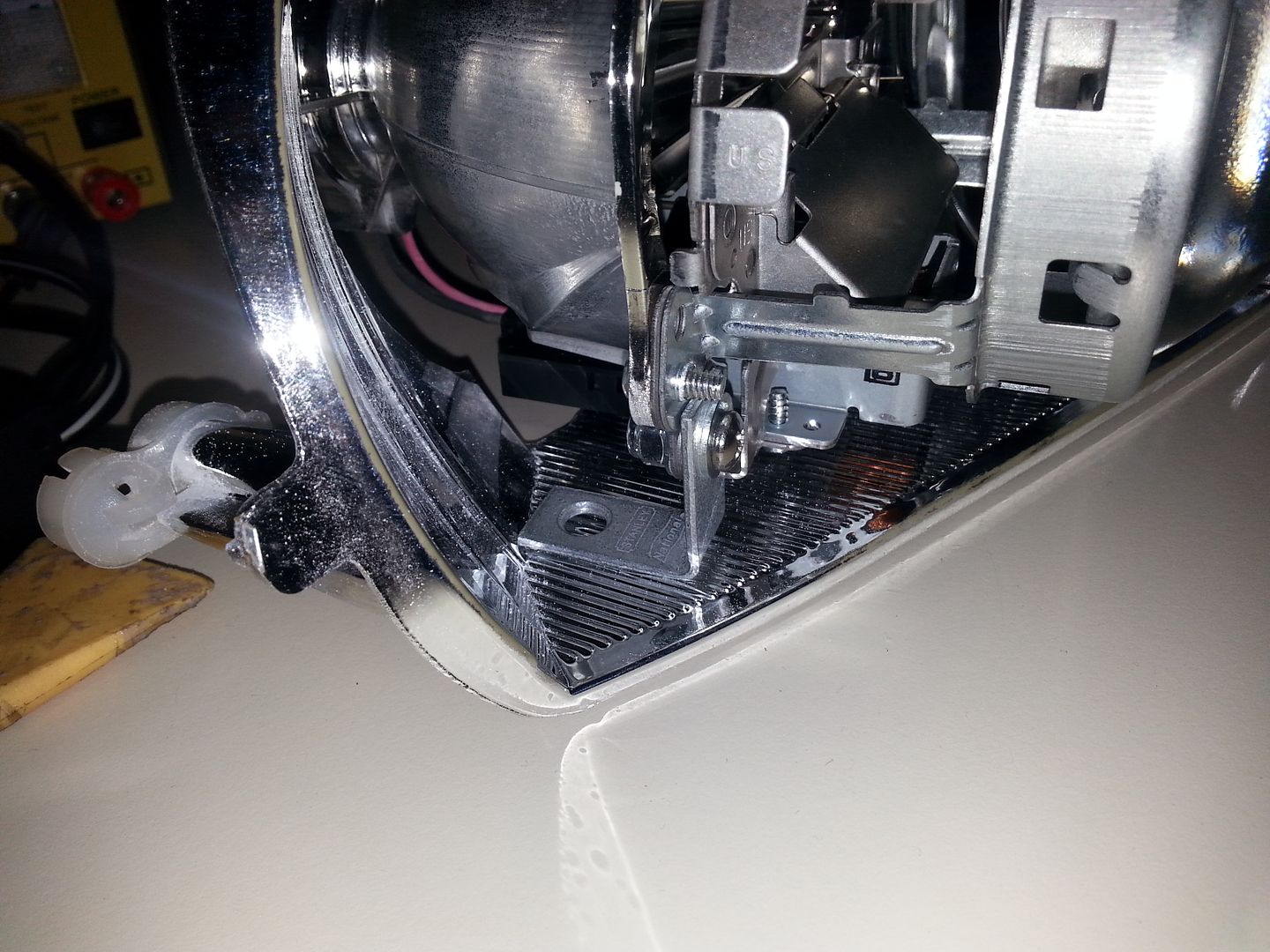

So I yanked them. Time to move on to the alignment issue. The bottom mounting screws on the high beam projectors were literally resting on the floor of the reflector bowls, and I needed a little more room to work with. The answer, was to notch the reflector bowl floors. That gave me enough room to rotate the projectors a little bit more.

So I yanked them. Time to move on to the alignment issue. The bottom mounting screws on the high beam projectors were literally resting on the floor of the reflector bowls, and I needed a little more room to work with. The answer, was to notch the reflector bowl floors. That gave me enough room to rotate the projectors a little bit more.

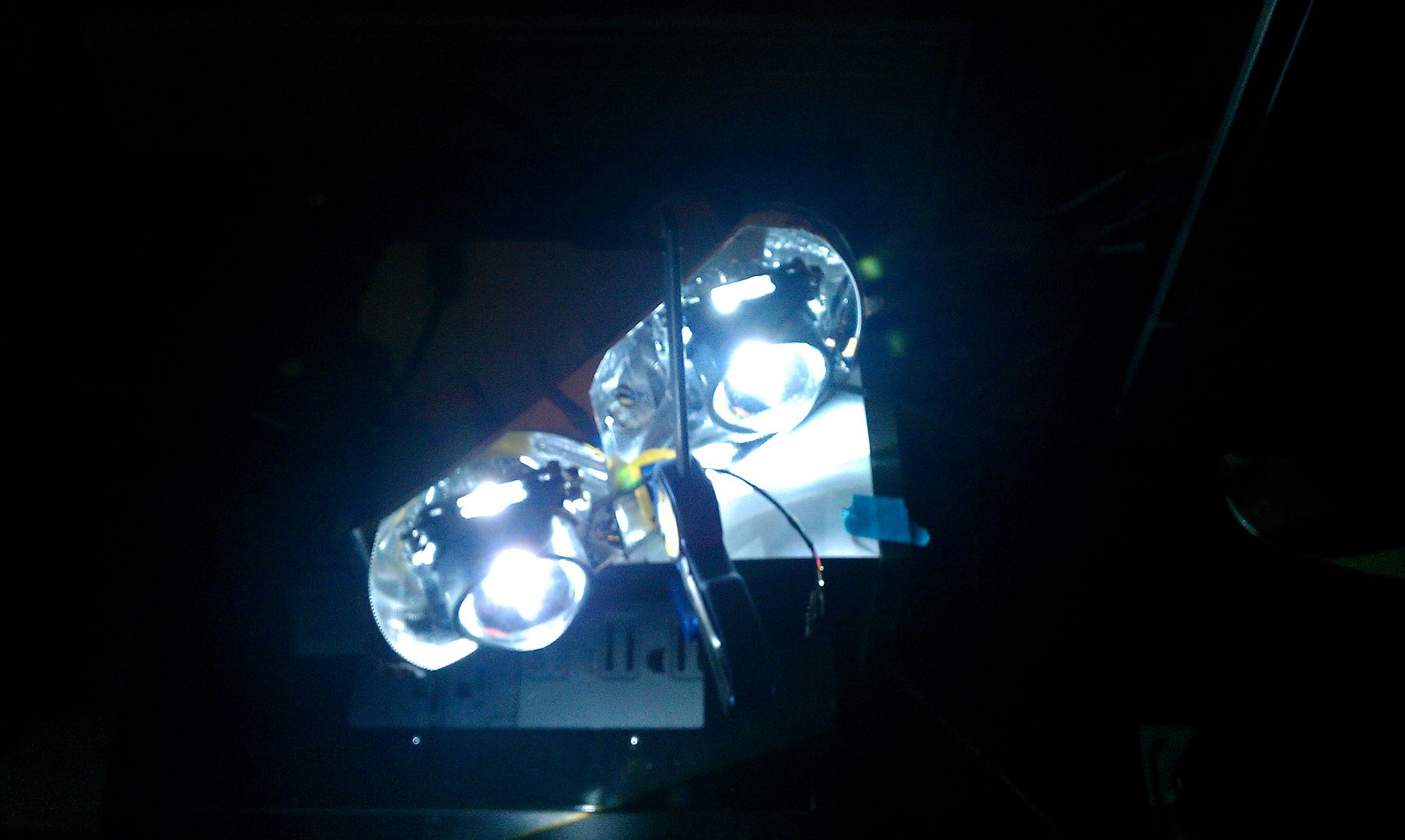

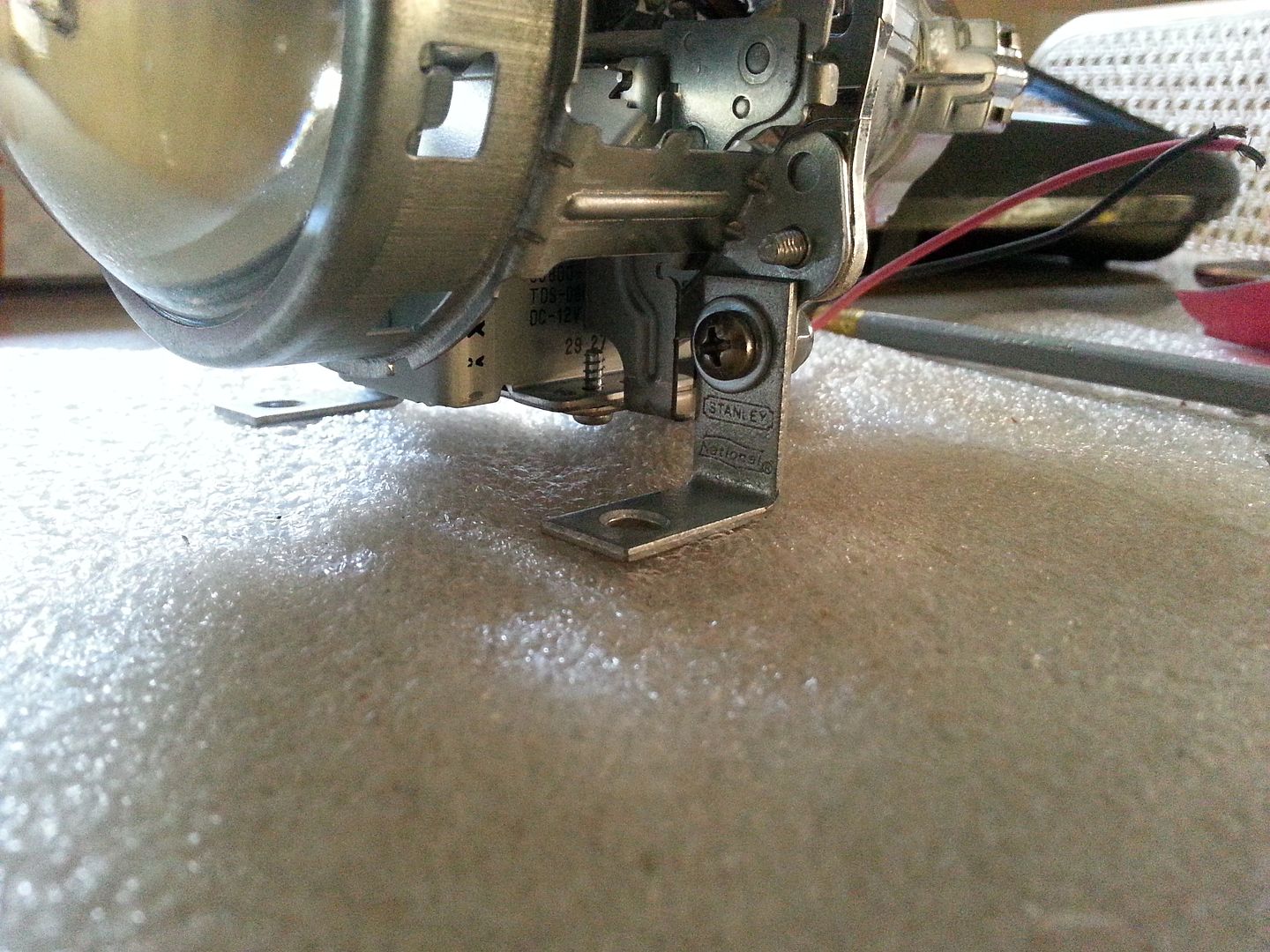

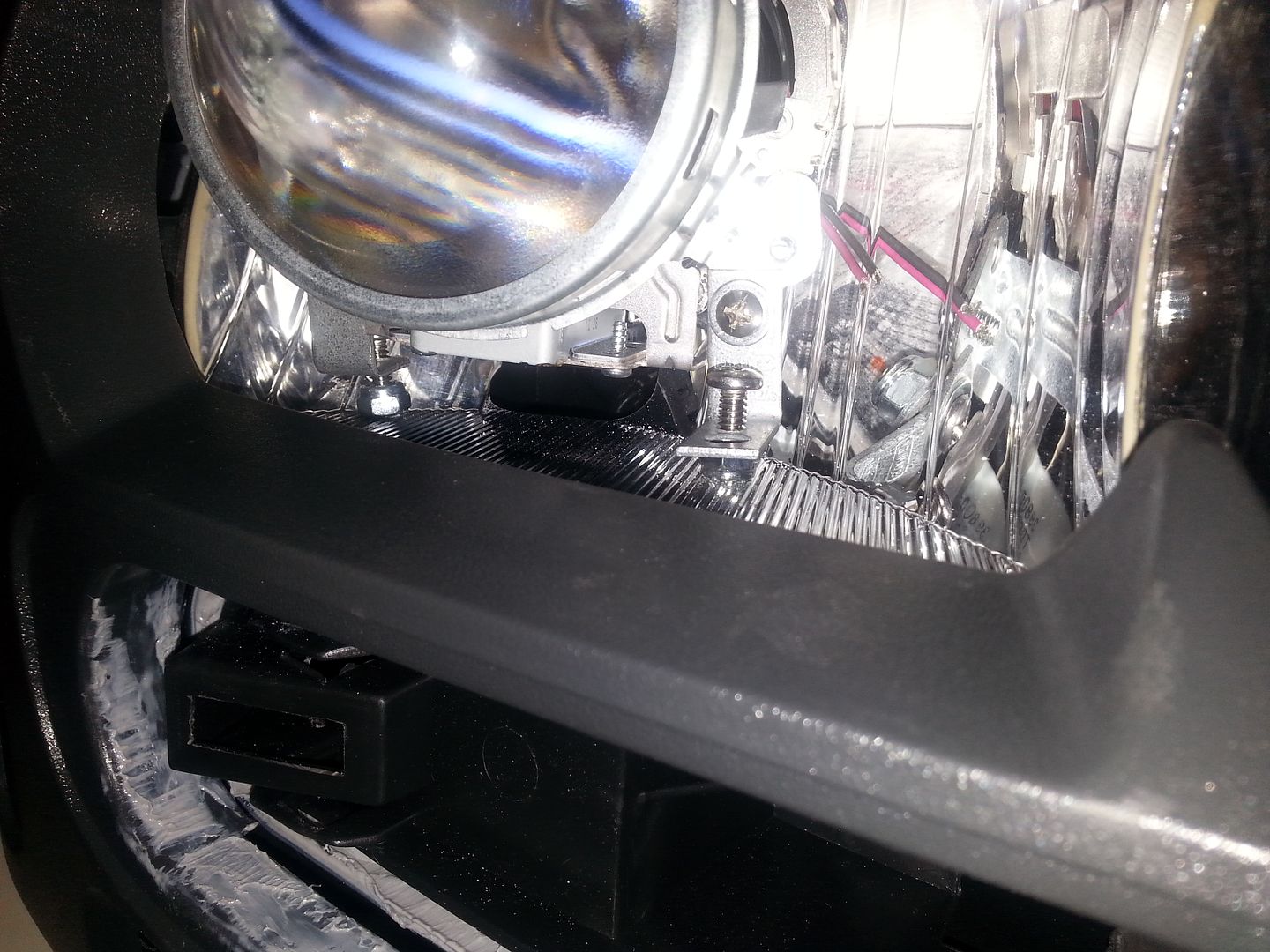

Somehow the position of the brackets weren't angled properly and the holes are too close together causing one side (left side of the pic) to not be straight up and down.

Somehow the position of the brackets weren't angled properly and the holes are too close together causing one side (left side of the pic) to not be straight up and down.

Here's a shot with 2 washers. A little bit more color above the cutoff, but also a bit more upward bowing.

Here's a shot with 2 washers. A little bit more color above the cutoff, but also a bit more upward bowing.