MRRSM

IDK im probably going to go get oem mounts today, I hate the vibrations and I don't trust Amazon recently they're dirty as hell nowadays.

Okay I'll try and get everything done and still existing problems, I'll try my best to keep everything in chronological order I might miss a few but if I remember anything I'll post it.

I've been slowly working on it over a period of time and drivability is best as I've seen since I had taken ownership.

I think the first things I started out with we're cleaning the throttle body and general brake maintenance

Had a coil pack go out after new fuel filter.

New cam pos sens.

Then went ahead and replaced upper and lower control arms lower control arm all ball joints on the front end. And sway bar links &bushings. Alignment afterwards. Detroit axle

Flushed power steering fluid. Not the fancy way but just by removing adding removing adding etc.

also at some point replaced the VVT solenoid it was aftermarket and the fuel pressure regulator also after market I'll post The Links at the bottom and tried my best to clean out the purge valve

New air filter and map sensor oem

Transmission fluid change with new filter and pan Gasket w new trans dipstick. Oem

Then came the valve cover gasket job.

New fan belt tensioner and idler pully oem

New iat or ait sensor not sure which one but it's the sensor before the resonator next to the accordion hose

Several oil changes in between work done at this point every time I used Pennzoil Platinum high mileage and once or twice used Lucas Oil stabilizer high mileage but haven't used it recently

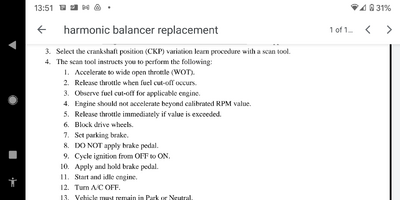

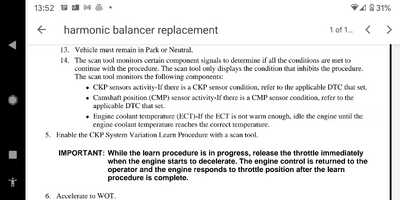

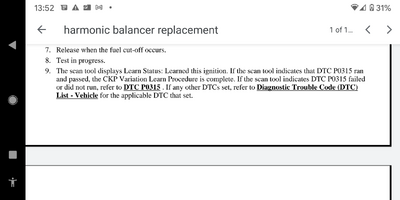

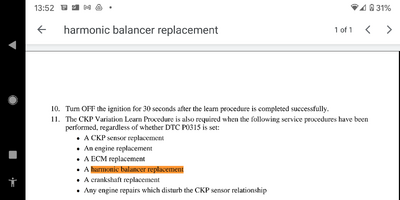

Harmonic balancer replacement oem and new front main seal.

All new acdelco plugs, didn't touch the gap

New thermostat oem I'm pretty sure.

new front end strut assemblies and rear shocks with rear sway bar links and bushings. Detroit axle

the most recent work was water pump and fan clutch replacement, I flushed radiator and new fluid.

Also I've done 2 piston soaks about 6months apart, first was mmo then recently b12, b12 had better results imo

But for now I think that's it, time span is about 18-20 months.

Mooseman-

The only cel codes I got were from before my valvecover gasket job. Going down the road got a p300 4 random misfire and the c e l was flashing haven't got the codes since.

Also I'm going to have to apologize for being such a dumb*$$, I was actually reading another thread you had commented on and noticed that the nipple looking cover above the fuel pressure regulator was just that, a cover.

While doing the valve cover gasket job I had cleaned the plenum and thought that it was just some kind of safety bumper. It had torn in the process, creating........

A vaccuum leak.

I used permatex 90 min black an reinstalled.. Its running noticably better and But it's still having some Issues.

Rpms have stabilized but still aren't where I think they should be, I read they should be around 650 and I'm getting around 590-615ish.

Vibrations are still lingering so I'm getting new mounts today if you guys think it's necessary. Autozone has em In stock.

I'm still getting fuel smell in cab right after starting. In probably going to get a fuel dye and uv light to see if there are any fuel line leaks.

I did go and check near fuel pressure regulator but it doesn't look like there's any leaks around it it was a cheap aftermarket fpr but it also if you guys think it's necessary I'll get a OEM because there has to be a reason there's an $80 difference in parts.

Here's the links for the am parts for you guys

VVT solenoid

Buy Dorman 917-010 Engine Variable Valve Timing (VVT) Solenoid for Select Models: Solenoids - Amazon.com ✓ FREE DELIVERY possible on eligible purchases

www.amazon.com

FPR

Buy AD Auto Parts New Fuel Pressure Regulator Herko PR4089 for GMC Chevrolet 2002-2005: Pressure Regulators - Amazon.com ✓ FREE DELIVERY possible on eligible purchases

www.amazon.com

Mounts, if I didn't already post

Let me know if there is any more info you guys need or live data, thanks.