For some time now, I've been thinking about the possibility of finding an additional way to prevent the GM 4.2L Engine Timing Chain from falling off of the Lower Crankshaft Gerotor Oil Pump Drive Cog. I obtained a New Timing Chain and a New Crankshaft Cog and since I had a Spare OEM Timing Chain Cover (with Gerotor Oil Pump In-Dwelling) I thought it worth examining their relationships in very close detail while looking for perhaps another way to "Skin This Cat".

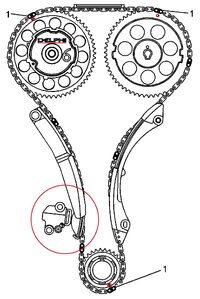

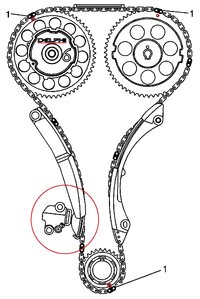

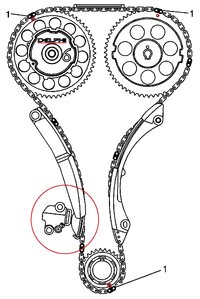

As you can see from the Attached Images, these all show the Progressive Build Up of this portion of the Timing Chain Drive System under the Installed Timing Cover near the Crankshaft. Note the presence of that Sloped Aluminum Chain Containment Shroud protruding out from the very bottom "Turnaround" location presents us with an opportunity of Confining the Chain Links Up Against the Lower Cog Teeth and thereby, preventing Gravity and Loss of Tension from allowing the Timing Chain from Dropping Down, Mis-Aligning or Re-Arranging itself out of this necessary and precise association:

Before the Timing Cover is installed and bolted up to the front of the LL8 Engine Block, one of the Black Links in the Timing Chain located at Seven Link Intervals MUST be aligned with the DOT embossed onto the Outer Lower Crankshaft Cog in roughly the 5 O'clock Position. It follows on that the Two Arrow Indicators embossed into the front plates of the Intake and Exhaust Camshaft Sprockets must likewise be fitted with Black Links at those Arrow Positions. As long at these Three Cogs have the Black Links installed and held in place by the Timing Chain Tensioner over the Two Timing Chain Guides, there should be no fear of any mis-alignments ever occurring with the Normal Engine Operations.

Once in Dis-Assembly, the latter two Upper Black Links alignments are easy enough to re-arrange during their installation. However, the same can NOT be said for ensuring that the Crankshaft Cog Teeth and the Black Link of the Lower Timing Chain will remain in position and NOT accidentally separate and slip away from one another by even One Single Tooth after the other two Sprockets have been unbolted or loosened in any way while the Timing Chain Tensioner is also "relaxed". If there is ANY Question about their alignment integrity, it becomes instantly necessary for the complications of completely removing the Front Timing Cover and Crank-Case Oil Pan.

But... "WHAT IF?" it were possible to USE the present design of the Timing Cover Casting to RESTRICT the Lower portion of the Timing Chain from Dropping or Falling Off of the Crankshaft Cog in a completely harmless and non-invasive manner? I am proposing this might be possible by using one of two methods to snake a Flexible Length of Spring Steel downwards and in between the narrow spacing of the Sloped Aluminum Shroud... and the Outer areas of the Lower Timing Chain Links positioned in place with the Teeth of the Crankshaft Cog. Please observe these images to explore this Idea a bit further.

One might accomplish this task using either a Large, Thick Plastic or Nylon Zip-Tie or a Coil of Spring Steel, such as from a Clock Spring or a Length of Spring Steel Band Ties used for binding Items in Wood Crates. By gradually snaking the chosen item down, around and in between those two surfaces, this would make it impossible for any of the Links in the Timing Chain while wrapped around the "Toothy" Lower Crankshaft Sprocket from separating from the other for the duration of this repair. Comme ça:

But the Big Question still remains: "How to Gain ACCESS to those sections of the Motor with everything else already installed while dealing with the limits of reach and an obstructed view down inside of the Engine Block?" Right now... these issues do seem to be insurmountable without at LEAST removing one of the Upper Sprockets to gain more room to move.

As you can see from the Attached Images, these all show the Progressive Build Up of this portion of the Timing Chain Drive System under the Installed Timing Cover near the Crankshaft. Note the presence of that Sloped Aluminum Chain Containment Shroud protruding out from the very bottom "Turnaround" location presents us with an opportunity of Confining the Chain Links Up Against the Lower Cog Teeth and thereby, preventing Gravity and Loss of Tension from allowing the Timing Chain from Dropping Down, Mis-Aligning or Re-Arranging itself out of this necessary and precise association:

Before the Timing Cover is installed and bolted up to the front of the LL8 Engine Block, one of the Black Links in the Timing Chain located at Seven Link Intervals MUST be aligned with the DOT embossed onto the Outer Lower Crankshaft Cog in roughly the 5 O'clock Position. It follows on that the Two Arrow Indicators embossed into the front plates of the Intake and Exhaust Camshaft Sprockets must likewise be fitted with Black Links at those Arrow Positions. As long at these Three Cogs have the Black Links installed and held in place by the Timing Chain Tensioner over the Two Timing Chain Guides, there should be no fear of any mis-alignments ever occurring with the Normal Engine Operations.

Once in Dis-Assembly, the latter two Upper Black Links alignments are easy enough to re-arrange during their installation. However, the same can NOT be said for ensuring that the Crankshaft Cog Teeth and the Black Link of the Lower Timing Chain will remain in position and NOT accidentally separate and slip away from one another by even One Single Tooth after the other two Sprockets have been unbolted or loosened in any way while the Timing Chain Tensioner is also "relaxed". If there is ANY Question about their alignment integrity, it becomes instantly necessary for the complications of completely removing the Front Timing Cover and Crank-Case Oil Pan.

But... "WHAT IF?" it were possible to USE the present design of the Timing Cover Casting to RESTRICT the Lower portion of the Timing Chain from Dropping or Falling Off of the Crankshaft Cog in a completely harmless and non-invasive manner? I am proposing this might be possible by using one of two methods to snake a Flexible Length of Spring Steel downwards and in between the narrow spacing of the Sloped Aluminum Shroud... and the Outer areas of the Lower Timing Chain Links positioned in place with the Teeth of the Crankshaft Cog. Please observe these images to explore this Idea a bit further.

One might accomplish this task using either a Large, Thick Plastic or Nylon Zip-Tie or a Coil of Spring Steel, such as from a Clock Spring or a Length of Spring Steel Band Ties used for binding Items in Wood Crates. By gradually snaking the chosen item down, around and in between those two surfaces, this would make it impossible for any of the Links in the Timing Chain while wrapped around the "Toothy" Lower Crankshaft Sprocket from separating from the other for the duration of this repair. Comme ça:

But the Big Question still remains: "How to Gain ACCESS to those sections of the Motor with everything else already installed while dealing with the limits of reach and an obstructed view down inside of the Engine Block?" Right now... these issues do seem to be insurmountable without at LEAST removing one of the Upper Sprockets to gain more room to move.

Attachments

Last edited: