so i was going to fill up my freon in my car however as soon as i put the gauge on the port it read 70 when it should be at like 40ish so i didnt put anything in. now since i bought the car about 3 months ago the vents always blow out hot air so i always figured the freon was low. other than changing the compressor and receiver/drier thing in the engine near the windshield? ive read the low pressure switch might be mad not letting the thing run. any input?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

air conditioner not working psi at 70

- Thread starter mrjean

- Start date

At 75F it should be at around 33-51 PSI. So if that's the temp it's overfilled. If you aren't getting any cool air then the low pressure switch could be bad. First you need to remove some of the refrigerant to get it to the proper pressure.

Then you need to remove the low pressure switch connector and jump it to see if the low pressure switch is bad.

This is where getting a subscription to Alldatadiy comes in handy. There is a section in there that describes step by step how to check the A/C system. There are also temperature to pressure tables as well.

Then you need to remove the low pressure switch connector and jump it to see if the low pressure switch is bad.

This is where getting a subscription to Alldatadiy comes in handy. There is a section in there that describes step by step how to check the A/C system. There are also temperature to pressure tables as well.

The compressor has to be running to get an accurate reading. If you simply put the fill line on the low pressure port without running the compressor, then you're not getting an accurate reading. You're getting a combination of the fill can pressure and the system without the compressor running.

Also, as Captain XL mentioned, overpressure will cause cooling problems also. If you're getting 70 psi, low side, with compressor running then it's too high. You'll need to recover some 134 out of the system.

Also, as Captain XL mentioned, overpressure will cause cooling problems also. If you're getting 70 psi, low side, with compressor running then it's too high. You'll need to recover some 134 out of the system.

meerschm

Member

- Aug 26, 2012

- 1,079

pressure when not operating (assuming there is enough to have liquid in the system) should follow this chart, and vary depeding on temp.

http://energy350.com/wp-content/uploads/2011/12/Refrigerant-Saturation-Curves.pdf

70 psi is about right for non-running, at around 70degrees f

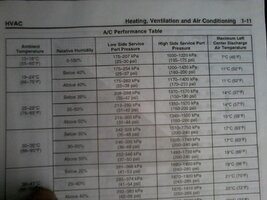

operating pressures will then go lower on low side, and higher on high side, depending on condition. you can find pressure tables based on temps. page from my service manual is here"

View attachment 28525

you should be able to watch the compressor pulley when the car is running and see if the clutch is operating. in normal operation it cycles on and off, depending on load, engine speed, and temps.

the low pressure switch is pretty cheap, but testing is a good idea. be sure you know what you are doing before any jumpering wires.

http://energy350.com/wp-content/uploads/2011/12/Refrigerant-Saturation-Curves.pdf

70 psi is about right for non-running, at around 70degrees f

operating pressures will then go lower on low side, and higher on high side, depending on condition. you can find pressure tables based on temps. page from my service manual is here"

View attachment 28525

you should be able to watch the compressor pulley when the car is running and see if the clutch is operating. in normal operation it cycles on and off, depending on load, engine speed, and temps.

the low pressure switch is pretty cheap, but testing is a good idea. be sure you know what you are doing before any jumpering wires.

Attachments

mrphoenix80

Member

- Jan 1, 2013

- 251

meerschm said:the charts are just a feel good item. the only way to properly set the required amount is to remove all R134a and refill by weight.

I was told in GM school the that R134 pressure follows temp at a 1:1 ratio pretty well. So on a static (nonrunning) system if the ambient air temp is 70F then you should be at around 70psi. My instructor went on to say that is why we like to see 30-40 psi on the low side in operation. That would tell us the low side (including the evap core) is around 30-40F.

The pressure switch on the side of the reciever/drier is just that, a switch. So if you jumper the 2 wires and "close" the switch the ac system will think there is enough pressure in the system for operation. If the compressor comes on then you need a switch. If not you have deeper issues that will need diag.

meerschm

Member

- Aug 26, 2012

- 1,079

CaptainXL said:Here are the static pressures on Alldatadiy. With the engine off both low and high side should read as follows.

Above 60F - 50 psi

Above 75F - 70 psi

Above 90F - 100psi

the link in post #4 leads to a chart with a wider range of values, but chasing precision at that level is somewhat academic, minor differences in readings from what you expect are likely traced to measurement error, either in estimated temperature or pressure measurement. but 70 PSI on both high and low sides at around 70 degrees f is normal for a system at rest.

usefulness is to know roughly what it should be if there is any liquid r134a in the system (which there should be). if the static reading is way under, you can rest assured (and be worried) that the R134 has leaked out. at rest, too little, just right, or too much r134a in the system will look the same. it only depends on if there is any liquid and gas in the system.

ok so i didnt know i had so many people showing me so much love on this lol

ok so i know nothing of the ac system however i am a do it yourself kind of person. i have done all kind of repairs on my car just from reading on here and the old site trailvoy. i went to autozone and it seems that everybodys freon ran out at the same time because they are making a killing lol. ok so here is what i know so far....and what i dont know.

car was purchased in march its a 2002 trailblazer ext lt. both the front and rear vents blow out regular air (not cold). i went with the fad and bought a bottle of freon. i turned the car on, set the ac on max and went to plug the bottle in. as soon as i plugged in it read 70 on the gauge. the weather outside these last 3-4 days in boston, ma have been around 90 degrees. due to this i didnt turn the dial so i returned the bottle. now, i read that the low pressure switch could be bad, but at a

$24 expense i didnt buy it without more troubleshooting (i cant return it). so what should i look for now? i dont hear anything kick in like in my old envoy. i could leave it on high for 30 minutes and nothing kicks in. i know theres something that runs of the belt (cant think of the name) and something up in the top of the engine by the windshield (cant think of the name).

i have read a few things here but honestly dont know how to do them and i WANT TO LEARN HOW TO DO THEM. i hate throwing money away at a shop when i could do it myself. if someone could walk me through the process of troubleshooting id appreciate it. me and the kids and wife cant take anymore of this 90 degree humid weather.

ok so i know nothing of the ac system however i am a do it yourself kind of person. i have done all kind of repairs on my car just from reading on here and the old site trailvoy. i went to autozone and it seems that everybodys freon ran out at the same time because they are making a killing lol. ok so here is what i know so far....and what i dont know.

car was purchased in march its a 2002 trailblazer ext lt. both the front and rear vents blow out regular air (not cold). i went with the fad and bought a bottle of freon. i turned the car on, set the ac on max and went to plug the bottle in. as soon as i plugged in it read 70 on the gauge. the weather outside these last 3-4 days in boston, ma have been around 90 degrees. due to this i didnt turn the dial so i returned the bottle. now, i read that the low pressure switch could be bad, but at a

$24 expense i didnt buy it without more troubleshooting (i cant return it). so what should i look for now? i dont hear anything kick in like in my old envoy. i could leave it on high for 30 minutes and nothing kicks in. i know theres something that runs of the belt (cant think of the name) and something up in the top of the engine by the windshield (cant think of the name).

i have read a few things here but honestly dont know how to do them and i WANT TO LEARN HOW TO DO THEM. i hate throwing money away at a shop when i could do it myself. if someone could walk me through the process of troubleshooting id appreciate it. me and the kids and wife cant take anymore of this 90 degree humid weather.

meerschm

Member

- Aug 26, 2012

- 1,079

first thing is, with the engine off, to raise the hood and find the air conditioning compressor. it is on the drivers side, below the generator.

might help to use a flashlight follow the serpentine belt location. you can reach down and see that the front of the compressor has a pulley with the belt on, and a plate in front. the plate can move separate from the pulley. an electric clutch operates to move the compressor with the pulley, or not and let the pulley move without moving the front plate or the compressor

note where the belt and fan are. you do not want to get close to these when the engine is running.

now start the engine, (with ac controls set for high fan and low temp, with ac on.) see if the compressor front clutch plate is moving, or not moving.

might help to use a flashlight follow the serpentine belt location. you can reach down and see that the front of the compressor has a pulley with the belt on, and a plate in front. the plate can move separate from the pulley. an electric clutch operates to move the compressor with the pulley, or not and let the pulley move without moving the front plate or the compressor

note where the belt and fan are. you do not want to get close to these when the engine is running.

now start the engine, (with ac controls set for high fan and low temp, with ac on.) see if the compressor front clutch plate is moving, or not moving.

meerschm

Member

- Aug 26, 2012

- 1,079

If you see that the compressor is working, next step would be to verify some coolness on the accumulator/dryer (metal top thing near the passenger firewall) I suspect this is not the likely case but you can verify. (if it is turning you need a set of guages to see what is going on, high and low.

if it is not working (meaning the pulley is moving but the front plate is not), then you need to figure out why. the compressor clutch is electrically operated, and there is a relay which drives it. the low pressure switch has to allow operation, and is a suggested frequent failure option. the compressor clutches get old and weak, and could be the issue, if the relay is energized and the voltage applied to the coil but the coil does not engage. could have a blown fuse, but if so, it is usually for a reason.

to troubleshoot you really need the wiring diagram (the suggested alldata can provide this, I think) and a meter. you can jumper around the low pressure switch, but should do so only for a short period. you will want to understand the wiring diagram before randomly jumping wires. if you see that the clutch is not engaging, you may decide to jumper across the low pressure switch for a moment or so ( I would think 15 seconds will tell you the answer) to see if the clutch kicks in, but then you should stop and get that switch you priced out. if you bypass the switch, it could damage other expensive components.

see http://gmtnation.com/f23/c-blowing-hot-air-2373/

the best bet really is to get to a shop and pay them to do a proper diagnosis. it will be a minimum one or two hundred. could just be low on r134a, could be something else. refrigerant is supposed to be loaded by weight, and too much can break.

( guy across the street has some experience, and was filling the AC in his jeep, (using a dual guage set after using a vacuum pump to evacuate the system) and blew the high pressure hose. it blew compressor oil all over the engine compartment, and not sure what else let loose )

)

My brother spent around $700 a year for several years keeping AC going, every winter left him with another thing wrong.

if it is not working (meaning the pulley is moving but the front plate is not), then you need to figure out why. the compressor clutch is electrically operated, and there is a relay which drives it. the low pressure switch has to allow operation, and is a suggested frequent failure option. the compressor clutches get old and weak, and could be the issue, if the relay is energized and the voltage applied to the coil but the coil does not engage. could have a blown fuse, but if so, it is usually for a reason.

to troubleshoot you really need the wiring diagram (the suggested alldata can provide this, I think) and a meter. you can jumper around the low pressure switch, but should do so only for a short period. you will want to understand the wiring diagram before randomly jumping wires. if you see that the clutch is not engaging, you may decide to jumper across the low pressure switch for a moment or so ( I would think 15 seconds will tell you the answer) to see if the clutch kicks in, but then you should stop and get that switch you priced out. if you bypass the switch, it could damage other expensive components.

see http://gmtnation.com/f23/c-blowing-hot-air-2373/

the best bet really is to get to a shop and pay them to do a proper diagnosis. it will be a minimum one or two hundred. could just be low on r134a, could be something else. refrigerant is supposed to be loaded by weight, and too much can break.

( guy across the street has some experience, and was filling the AC in his jeep, (using a dual guage set after using a vacuum pump to evacuate the system) and blew the high pressure hose. it blew compressor oil all over the engine compartment, and not sure what else let loose

)

)My brother spent around $700 a year for several years keeping AC going, every winter left him with another thing wrong.

im actually going to take it to a shop to get it checked out, im just scared that they might misdiagnose a lps and tell me its something way more expensive. tomorrow i will check the compressor, clutch and all the other stuff mentioned here. what would keep it from working? a lps? or something more serious?

a friend of mine wants to know where all the relays for the ac are so he can make sure they all work. i honestly dont know. i did check all the fuses under the hood and under the second row and they all work. can say for the relays becuase i obviously cant/dont know how to check em.

a friend of mine wants to know where all the relays for the ac are so he can make sure they all work. i honestly dont know. i did check all the fuses under the hood and under the second row and they all work. can say for the relays becuase i obviously cant/dont know how to check em.

meerschm

Member

- Aug 26, 2012

- 1,079

could be the LPS, could be clogged evaporator or condenser, could be the compressor. could be the compressor clutch. (which a shop would likely replace the compressor)

good idea to go the a shop that is experienced. it does take specialized tools and knowledge to diagnose and repair the system, and load the proper amount of R134a.

good luck. and be careful.

good idea to go the a shop that is experienced. it does take specialized tools and knowledge to diagnose and repair the system, and load the proper amount of R134a.

good luck. and be careful.

So took it to a shop and they got under the car with a reader and said its the compressor. The wires going to the comoressor have current to them but the compressor itselfs is bad. Now my question.. how often is it the clutch bearing pulley compared to the whole actual compressor gone bad??

meerschm

Member

- Aug 26, 2012

- 1,079

not sure it matters a lot,

if you want to try, you could try to find and order a rebuilt clutch kit, and replace it. ( I have chosen this course, but keep putting off the install. this is not my daily driver, just an extra car. in my case I know the rest of the system works, because it just quits when it is hot) you have an EXT, but my short base seems a little hard to get to the front of the compressor. I will get it done sooner or later, but no hurry. if it is not done by the 4th of July I will take another car on next scheduled road trip.

could work, could not. sounds like it has not been operating for a while, but has some R134a in the system. does the clutch seem like it turns easy (would at least tell you the compressor can rotate) if it does not want to turn, i would think the compressor is really trashed, and you would likely need to flush some stuff and replace a few extra items. not really a fun diy.

how much did they give you for a price to fix?

if they do the work, you will know the right amount of r134a is filled, and know who to complain too if it ends up breaking later, (over ten years old, would not be a news flash if something else went in a few months or a year or so) (and you will have some cool air next week. I bet all that black paint gets hot in the sun.)

if you want to try, you could try to find and order a rebuilt clutch kit, and replace it. ( I have chosen this course, but keep putting off the install. this is not my daily driver, just an extra car. in my case I know the rest of the system works, because it just quits when it is hot) you have an EXT, but my short base seems a little hard to get to the front of the compressor. I will get it done sooner or later, but no hurry. if it is not done by the 4th of July I will take another car on next scheduled road trip.

could work, could not. sounds like it has not been operating for a while, but has some R134a in the system. does the clutch seem like it turns easy (would at least tell you the compressor can rotate) if it does not want to turn, i would think the compressor is really trashed, and you would likely need to flush some stuff and replace a few extra items. not really a fun diy.

how much did they give you for a price to fix?

if they do the work, you will know the right amount of r134a is filled, and know who to complain too if it ends up breaking later, (over ten years old, would not be a news flash if something else went in a few months or a year or so) (and you will have some cool air next week. I bet all that black paint gets hot in the sun.)

mrphoenix80

Member

- Jan 1, 2013

- 251

Just me here but I would price out the compressor and the clutch (both parts and labor). I often find that the difference is only like $30-40. The compressors also have a warranty with them. Is the difference in cost worth it, or is the warranty and piece of mind better. I often find a new compressor is the way I go.

Btw I do the same for most things on the cars I work on. A torn CV boot looks like this in my mind $20 for the boot +1/2hr to disassemble the shaft and install the boot+the mess, or $50 for a new CV shaft. The choice is easy then

IF you want to verify the clutch is bad. I would jumper the 2 contacts on the low pressure switch( located on the can next to the coolant overflow bottle) and have some one watch the clutch. IF it starts to turn it is ok. If not you know the shop is telling you the truth(most likely).

Btw I do the same for most things on the cars I work on. A torn CV boot looks like this in my mind $20 for the boot +1/2hr to disassemble the shaft and install the boot+the mess, or $50 for a new CV shaft. The choice is easy then

IF you want to verify the clutch is bad. I would jumper the 2 contacts on the low pressure switch( located on the can next to the coolant overflow bottle) and have some one watch the clutch. IF it starts to turn it is ok. If not you know the shop is telling you the truth(most likely).

mrjean said:how often is it the clutch bearing pulley compared to the whole actual compressor gone bad??

Usually in a properly working system with a good amount of oil the clutch will go out before the compressor.

The HVAC technicians creed is "compressors never go out by themselves, usually something else caused it."

Like phoenix80 said, if the clutch engages and rotates the compressor then the shop is probably feeding you a line of bull. Always get a few quotes for stuff like this. A/C work can be over $1000.

meerschm

Member

- Aug 26, 2012

- 1,079

If you look at Rock Auto, it does not look like it. if you have rear ac your system would have two expansion valves and two evaporator coils.

there are a few places on line which will sell you replacement kits (compressor and dryer with screen and a few other parts) you may want to price compare. somewhat depends on how long you plan to keep driving the TB.

there is a bit of a steep entry cost to really do ac work correctly.

you could see if the place would recover the r143a, let you bolt parts together, and then recharge. might save some money that way. might work if you let them change the dryer just before they evacuate the system for recharge. (tell them you want to do some of the work, they may be ok with it and let you get to the compressor, but they may not be too keen on it, since they could end up chasing your learning curve. doesn't hurt to ask)

I doubt the local place will back up the repair if you do the work, just have to ask, and figure all the costs and risks into your decision. heck, it might be a cool summer.

there are a few places on line which will sell you replacement kits (compressor and dryer with screen and a few other parts) you may want to price compare. somewhat depends on how long you plan to keep driving the TB.

there is a bit of a steep entry cost to really do ac work correctly.

you could see if the place would recover the r143a, let you bolt parts together, and then recharge. might save some money that way. might work if you let them change the dryer just before they evacuate the system for recharge. (tell them you want to do some of the work, they may be ok with it and let you get to the compressor, but they may not be too keen on it, since they could end up chasing your learning curve. doesn't hurt to ask)

I doubt the local place will back up the repair if you do the work, just have to ask, and figure all the costs and risks into your decision. heck, it might be a cool summer.