- Dec 6, 2011

- 674

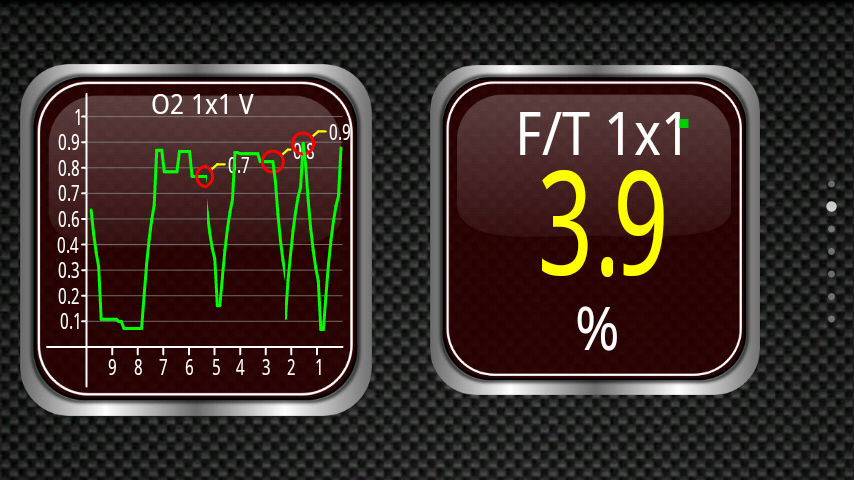

I finally replaced my marginal thermostat (no codes, but big temperature dips on acceleration and during warm-up that take a long time to recover). However, I think I may have waited too long.

I scoped my upstream O2 sensor last night and I'm getting <1/2Hz (more than 2seconds/cycle).

I know O2 sensor replacement has been discussed ad nauseum but:

I'm shopping for a replacement (I know to stick to AC Delco) and I see to two part numbers:

2133539 - Original Equipment

2134348 - Professional

What's the difference? Catalog says both apply to 2006 MY. Does the "professional" sensor justify twice the cost? Is it a durability issue?

Also, would a clogged cat converter itself cause the sluggish readings (and the sensor might be fine)?

I plan on doing an exhaust back pressure test while I have the sensor out but I'd like to have a replacement sensor on hand in case my only option is cutting the wires (split socket slipped once already--gonna PB Blaster it for a few days).

I scoped my upstream O2 sensor last night and I'm getting <1/2Hz (more than 2seconds/cycle).

I know O2 sensor replacement has been discussed ad nauseum but:

I'm shopping for a replacement (I know to stick to AC Delco) and I see to two part numbers:

2133539 - Original Equipment

2134348 - Professional

What's the difference? Catalog says both apply to 2006 MY. Does the "professional" sensor justify twice the cost? Is it a durability issue?

Also, would a clogged cat converter itself cause the sluggish readings (and the sensor might be fine)?

I plan on doing an exhaust back pressure test while I have the sensor out but I'd like to have a replacement sensor on hand in case my only option is cutting the wires (split socket slipped once already--gonna PB Blaster it for a few days).

That's exactly the kind of info I was looking for.

That's exactly the kind of info I was looking for.