Hello again

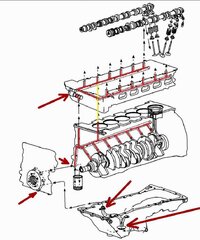

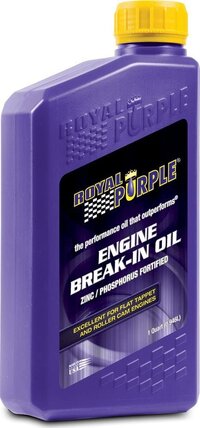

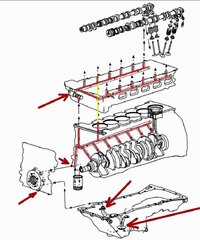

Another crazy question. Is there a way to pre-lube a 4.2? I've done more SBC than I can count using a primer and a drill and a mechanical oil gauge. Can make sure everything is well lubed before first crank

Anyway to easily (yes I can't believe I used that word in the Trailblazer world) accomplish this

Another crazy question. Is there a way to pre-lube a 4.2? I've done more SBC than I can count using a primer and a drill and a mechanical oil gauge. Can make sure everything is well lubed before first crank

Anyway to easily (yes I can't believe I used that word in the Trailblazer world) accomplish this