I'm about 2/3 of the way through the series, and just got to the part where the oil pan is off and we get our first look at the pickup screen. Or, putting it another way... "trust me, there's a screen under there"

Was surprised to see it looked this bad -- you can tell he pretty much kept the oil changed, when he took this off at 265K (?) and he had the truck from new.

By comparison, my pickup tube on the 6.0L wasn't clogged

at all - and it had a TON of sludge inside the pan (I bought it with ~ 230K on the clock). My build thread shows the pan in detail. The shape of the inlet is different between the 4.2L and mine - but the amount of surface area looks to be about the same.

So... things I've picked up from watching this series, so far...

- The video creator, and some people who entered comments... have stated that shutting down the engine for a few seconds, then restarting it, temporarily resolves the problem. If the OP has found the same... I'd definitely apply that process, and let this wait until temps get warmer, given the typical usage of the vehicle that he's described earlier.

- I'd do a semi-permanent install of a good oil pressure gauge, like he did in the series, and teach the GF to look at it. Maybe run it along the D/S fender / cowl, so she doesn't have to look across to see the tiny markings. Also teach her that that dash 'gage' (I hate to even use the term) is utter crap, and not to be trusted. It's basically an on/off switch.

I'd also install it in the same place he did - the galley plug, and *not* replace the pressure sending unit with it, as someone advised in the comments. While it may not be 'as' accurate as connecting it to the boss for the sending unit... if the pressure sensor is eliminated, the truck is going to show 'no oil pressure', because it won't be receiving a report from the sensor. Plus it will worry the GF.

- If the pickup winds up looking like the pic above, that

has to be the issue. I'd look less toward the pump & rebuilding it -- but if you really

have to take the front cover off to remove the front hold down bolt on the pickup tube... then I'd replace / rebuild the associated parts. I need to see a pic of how that front tube connects in from the underside -- it just might be possible to get a wrench in from underneath. And -- it may be possible to thread the bolt back in from the bottom end, vs. the top. But I have to look at that area before I can judge. You definitely want to replace the O-ring and gasket, and truth be told, I'd just replace the entire tube, unless you can snake a cam down the entire length and ensure there aren't areas in it that look like the inlet screen.

- It may be beneficial, while you have the colder winter temps, to change the oil viscosity -- not to a *thicker* rated, but to a *

thinner* rated oil (I'm thinking 5w-20). My theory is that the viscosity of the 5w-30 thickens, and can't make it through the pickup screen, when it does (from all accounts -- both the OP, and YT --, this happens after about 20min of driving, about the time where you'd expect that oil to be at its 'hot' viscosity.

The beauty of this, is that you don't have to take a thing apart, to try it. It'll only cost what 7qts of what you can find 5w-20 for. I'd use a syn blend high-mileage (actually, I don't know if there's any 5w-20 that's not at least a synthetic blend, TBH.) That would get you through to the warmer temps, where this could be repaired correctly.

That would be my plan, in the short-term. YMMV.

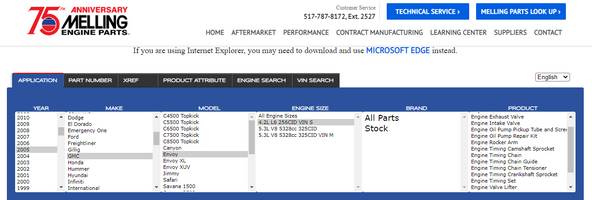

Whenever you do go to do the repair, see if there's a 'HD' or revised pickup with more screen area. I'm just going by what I can see from the one pic, but I'd like to see more screen area (not a bigger diameter tube, as that will affect pressure & volume and probably put it outside the operating specs of the pump. But if I could find a pickup tube with more screen area, I'd look to make the spend for it.

I'll look for some pics of where the pickup tube front bolt connects to the pump, and jump back in once I can see what's going on in that area. Again, if the front cover *has* to come off... I'd rebuild the oil pump for sure (and put a new WP in, since that would have to be removed, as well). Of the two, the WP fails the most, by far. Not too often you hear of a crank-driven gerotor-style oil pump going bad (but it does / can happen.)

I stopped looking at the diagram, and looked up the text description. Found multiple places where it's exactly as you describe. Pickup > pump > filter > galleys > lower end / upper end. I wish the LS' stock oiling was similar.

I stopped looking at the diagram, and looked up the text description. Found multiple places where it's exactly as you describe. Pickup > pump > filter > galleys > lower end / upper end. I wish the LS' stock oiling was similar.