Hey everyone. I'm working on my girlfriend's 05 Envoy with the 4.2 and could use some help.

The issue started with the pressure gauge dropping to 0 while driving. Would jump back up and then down again. I know the gauge is fake, so I figured just a bad switch.

I replaced the switch, and did an oil change, but the problem persists.

When the truck is first started, everything is fine, but after driving for about 10 minutes the gauge drops to 0 and stays there.

It's definitely a pressure issue, because the lifters will start to sing if the truck isn't shut off when this happens.

I've ran a quart of flush through the engine, followed by draining the oil, and filling the pan with a gallon of diesel through the dipstick tube, and letting it soak for a few days, hoping that maybe the pickup screen was getting clogged.

Today I drained the diesel, filled with new oil, ran the engine for about 5 minutes, drained again, followed by new oil, 5 more minutes running, then drained again and added 7 qts of new oil, and a new filter.

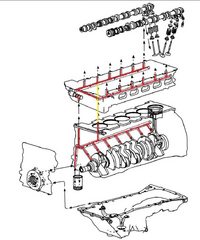

Took the truck for a drive and the problem is still there. Not sure what to do from this point. I thought about changing the pump, but it's a 4wd, and I'm told that it's about a 4 day job.

I plan on hooking up a manual gauge to it today to see what the real pressure is.

Only other problem with the truck that I'm aware of is that it needs a new thermostat. The one in it now won't allow the engine to get over about 135-140f while driving, and about 150f at idle, which is causing condensation buildup.

The issue started with the pressure gauge dropping to 0 while driving. Would jump back up and then down again. I know the gauge is fake, so I figured just a bad switch.

I replaced the switch, and did an oil change, but the problem persists.

When the truck is first started, everything is fine, but after driving for about 10 minutes the gauge drops to 0 and stays there.

It's definitely a pressure issue, because the lifters will start to sing if the truck isn't shut off when this happens.

I've ran a quart of flush through the engine, followed by draining the oil, and filling the pan with a gallon of diesel through the dipstick tube, and letting it soak for a few days, hoping that maybe the pickup screen was getting clogged.

Today I drained the diesel, filled with new oil, ran the engine for about 5 minutes, drained again, followed by new oil, 5 more minutes running, then drained again and added 7 qts of new oil, and a new filter.

Took the truck for a drive and the problem is still there. Not sure what to do from this point. I thought about changing the pump, but it's a 4wd, and I'm told that it's about a 4 day job.

I plan on hooking up a manual gauge to it today to see what the real pressure is.

Only other problem with the truck that I'm aware of is that it needs a new thermostat. The one in it now won't allow the engine to get over about 135-140f while driving, and about 150f at idle, which is causing condensation buildup.

A bung for a pressure gauge or oil return is fine - on the side of the pan. 'Nuff said

A bung for a pressure gauge or oil return is fine - on the side of the pan. 'Nuff said