Don't Do ANYTHING to it... It should have come from the Factory pre-loaded correctly within the possible range of 0-25 Degrees ..

.AND... The Metal Restraint Tab inside of it can be very easily Broken Off by Accidental Excess Manipulation. The action of the PCM via the VVT CPAS (Solenoid) and varied Oil Pressure that changes dynamically from the Gerotor Oil Pump moving oil in subtle pressure variations depending upon Engine RPM does all the work after that. Most of the Cam Phaser's "EGR"- like behavior that the LL8 Engine exhibits occurs at lower and idle RPM. But the Cam Phaser's actions have a dramatic effect upon the Engine Power Band through a fairly wide range of Engine RPM and Torque conditions.

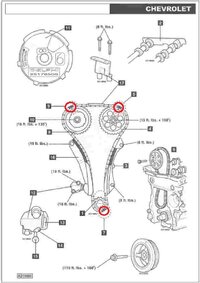

As far as confirming your correct installation, you should know that if you have conformed with the Alignment Pattern shown in the image attached below, after following the positions of having the Black Links situated at every Seventh Link fitted on top of the Designation Marks on the Cam Phaser and the Intake Camshaft Sprocket as well the one that should be found at 5 O'clock Position "DOT" on the Outer Crankshaft Gear Cog indicating the #1 Cylinder is at TDC...

then all will be well.

Once these references have all been confirmed... it is very important to remember to

"Pull The Grenade Pin" on the Retention Pin holding the Timing Chain Tensioner in Spring Compression to release the Contact Push Pad against the Passenger Side Timing Chain Guide. After these actions are done and you have

REMOVED THE SPECIAL CAMSHAFT ALIGNMENT TOOL from the back of the Two Camshafts, the next and last method for confirmation is to Rotate the Engine Clockwise at the Crankshaft Bolt (14) Fourteen Times in a Row in order for this Installation Geometry to arrive back at this Imaged Correct Alignment Starting Point. If this occurs and you feel No Inordinate Mechanical Resistance to these actions, then you will be done.

It only remains to use either the Approved GM OEM Factory ACDelco Engine Gray Sealant, or the correct flavor of the Permatex Brand High-Temp Gray Silicone Sealant upon the inner flange surfaces of the Timing Cover. After cleaning the Timing Cover Flange and the Mating Front Engine Block Surfaces with Acetone or Lacquer Thinner as a de-greasing method, squeeze out a 3mm Wide Bead of Sealant into the appropriate Grooves and around the Fastener Buss Points. Next, install the Timing Cover uniformly, without allowing it to

'Slip-N-Slide' onto the Engine Block, being mindful of the proper placement by length and the correct positioning of all the Fasteners.

Do NOT Freelance with screwing in those Fasteners Too Tight.

Tighten them down in the Proper Pattern using three passes leading to the final, mild GM Factory Torque necessary for a Good, Oil and Water Tight Seal. It is important not to skimp on the correct installation procedures here, since the Timing Cover - Gerotor Oil Pump also serves as a Supporting Structural Member to the GM 4.2L Atlas LL8 Engine making it Rigid and Strong. Remember that the effective "Work Time" of the ACDelco Sealant is Only Ten Minutes, so do NOT begin these procedures before you have everything necessary on hand before you start doing this job.

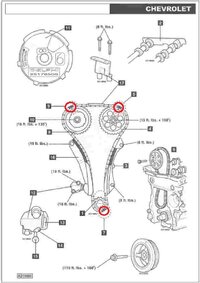

Take Note of these Torque Sequence Limits as

"Do NOT Exceed These Limits " Warnings as shown on THIS Diagram: