<rant>

I don't know if just Firestone is horrid all over America or all franchise alignment shops are. I have been to alignment shops in about 4-5 states over the years and I have never had a good experience with any of them. I tried sears too and it was just as bad. The steering wheel is always crooked on any vehicle I take to any of these shops. I have had to take vehicles to shops a min of 3 times to get them to ever do it right, visiting different ones until I find a good tech. Sears I had to go to 2 different locations with the last location getting the manager involved, who understood, and actually fixed my vehicle. From an old honda, a brand new Ford Focus, a newish equinox, and then to the trailblazer now they can never seem to get it right.

I even had the dealer do it right once and they completely fucked it up. Washington State, Pennsylvania, Tennessee, Georgia, North Carolina, Alabama. They all suck. One time in Alabama I saw them lowering a car and they destroyed that one somehow crumpling a part of the body. What the hell is the deal?

</rant>

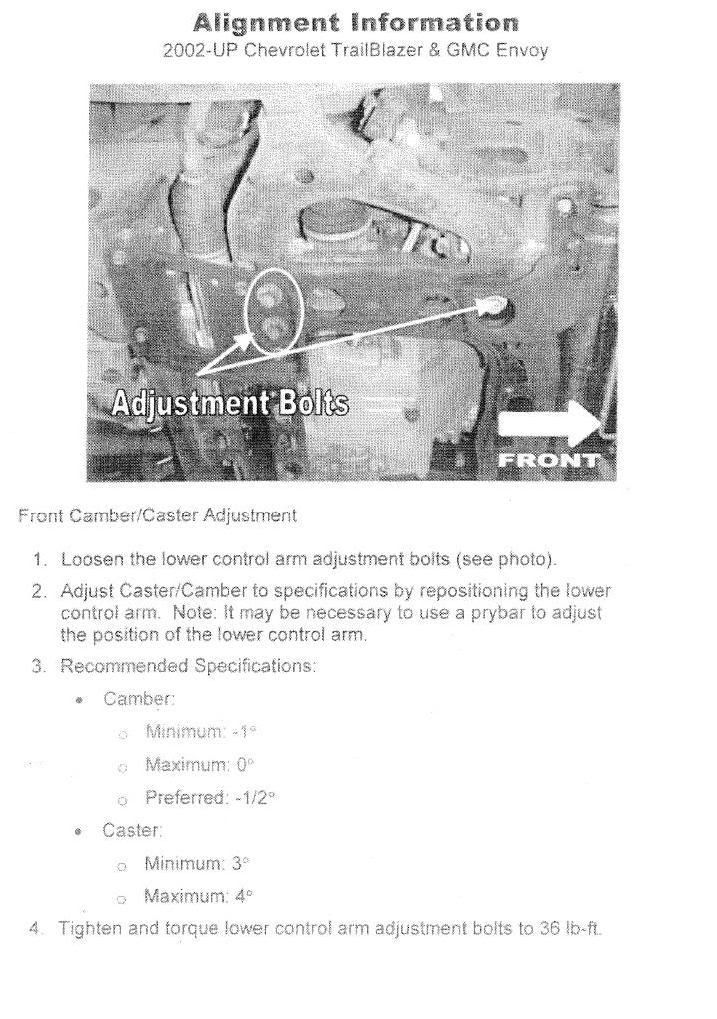

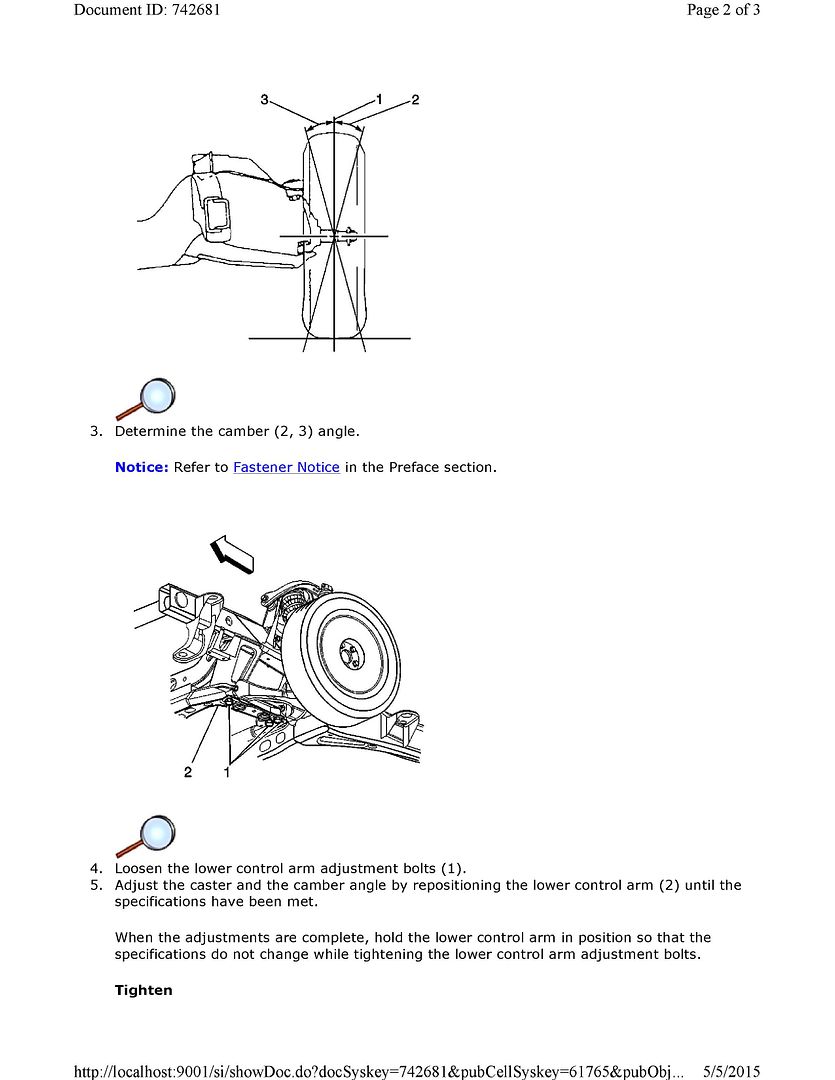

So the 2004 Trailblazer. The first tech to look at it started talking to me about how my rear wheels are loose and there is no way to align it. That when the car is jacked up you can pull them in and out. Is there supposed to be absolutely no play in the rear diff? (In and out) I was told that it was fine. I ended up taking it back and getting an alignment and they had to fix the camber. (I guess you have to use a pry bar?) They kept giving excuses like it was impossible. They ended up getting it right though.

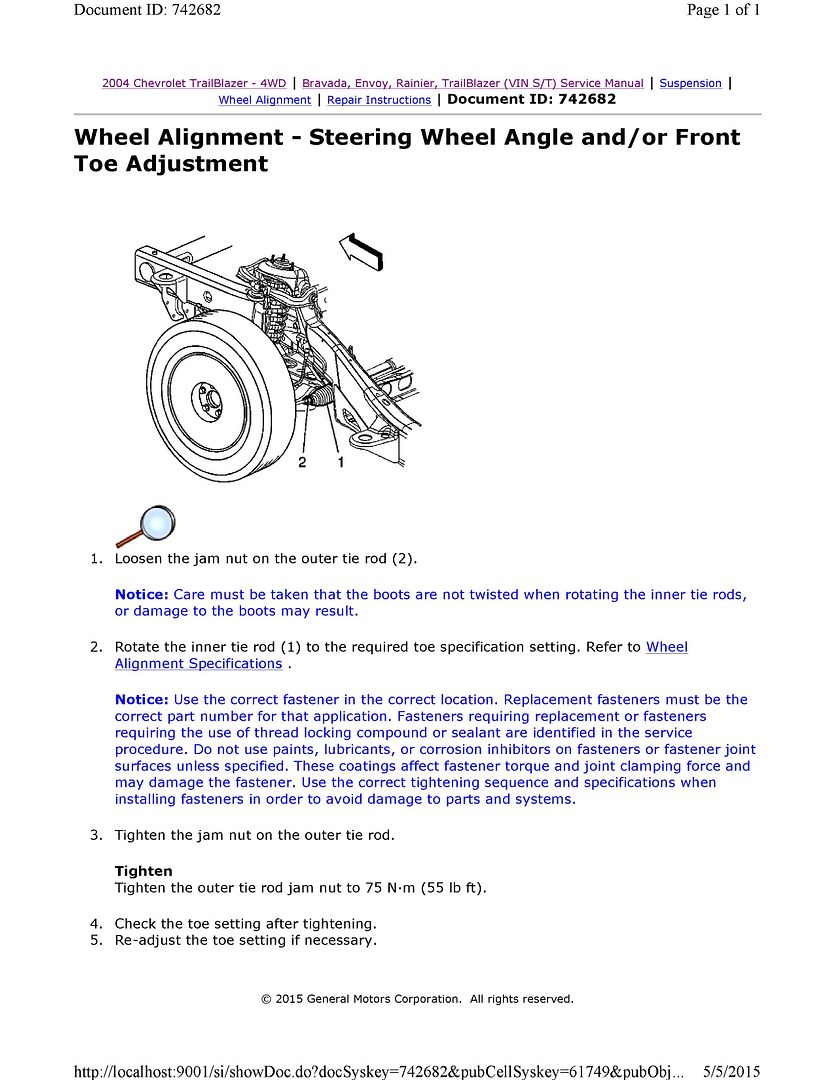

The steering wheel was off but the alignment seemed to be right. I needed to drive it for a while. I just took it back last weekend to get the steering wheel strait and they (Firestone) tell me my caster is off and that they do not have the tool to adjust it, and that they are not even required to adjust it. They did say if I get the tool, that they would do it, or if I came back during the week they would do it because they could get the tool. I want to do it on the weekend so I was just going to buy the tool to have. Do they really need a tool to fix this? What gives?

Is this what they are talking about: http://www.amazon.com/OTC-7840-Caster-Camber-Adjusting/dp/B000O80B1G

or

Is this what they need?: http://shop.advanceautoparts.com/p/lisle-caster-camber-adjuster-for-gm-vehicles-lis32510/25961520-P

Will this work?

Now the car is not aligned and the steering wheel is still off but the other way.

I don't know if just Firestone is horrid all over America or all franchise alignment shops are. I have been to alignment shops in about 4-5 states over the years and I have never had a good experience with any of them. I tried sears too and it was just as bad. The steering wheel is always crooked on any vehicle I take to any of these shops. I have had to take vehicles to shops a min of 3 times to get them to ever do it right, visiting different ones until I find a good tech. Sears I had to go to 2 different locations with the last location getting the manager involved, who understood, and actually fixed my vehicle. From an old honda, a brand new Ford Focus, a newish equinox, and then to the trailblazer now they can never seem to get it right.

I even had the dealer do it right once and they completely fucked it up. Washington State, Pennsylvania, Tennessee, Georgia, North Carolina, Alabama. They all suck. One time in Alabama I saw them lowering a car and they destroyed that one somehow crumpling a part of the body. What the hell is the deal?

</rant>

So the 2004 Trailblazer. The first tech to look at it started talking to me about how my rear wheels are loose and there is no way to align it. That when the car is jacked up you can pull them in and out. Is there supposed to be absolutely no play in the rear diff? (In and out) I was told that it was fine. I ended up taking it back and getting an alignment and they had to fix the camber. (I guess you have to use a pry bar?) They kept giving excuses like it was impossible. They ended up getting it right though.

The steering wheel was off but the alignment seemed to be right. I needed to drive it for a while. I just took it back last weekend to get the steering wheel strait and they (Firestone) tell me my caster is off and that they do not have the tool to adjust it, and that they are not even required to adjust it. They did say if I get the tool, that they would do it, or if I came back during the week they would do it because they could get the tool. I want to do it on the weekend so I was just going to buy the tool to have. Do they really need a tool to fix this? What gives?

Is this what they are talking about: http://www.amazon.com/OTC-7840-Caster-Camber-Adjusting/dp/B000O80B1G

or

Is this what they need?: http://shop.advanceautoparts.com/p/lisle-caster-camber-adjuster-for-gm-vehicles-lis32510/25961520-P

Will this work?

Now the car is not aligned and the steering wheel is still off but the other way.

There's nothing mythical about these vehicles when it comes to an alignment. I have heard of shops saying that the camber cannot be adjusted on our vehicles because it doesn't "look" like it can be. This is completely untrue and the only special tool, if you can call it that, needed is a crow bar. There are tools that can make the job easier but are in no way required.

There's nothing mythical about these vehicles when it comes to an alignment. I have heard of shops saying that the camber cannot be adjusted on our vehicles because it doesn't "look" like it can be. This is completely untrue and the only special tool, if you can call it that, needed is a crow bar. There are tools that can make the job easier but are in no way required.