- Oct 20, 2014

- 14

My wife complained of a whining noise while driving. I drove the car in circles and the noise increased when turning left and disappeared when turning right. Sounded like a wheel bearing but there was no play whatsoever in the wheel. After doing some reading on the other forum (by the way, I'm really glad The-Roadie posted the link to this new forum in that Pittman arm puller photo that I stumbled across), I suspected the axle disconnect on the passenger side. I was able to get the half axle out pretty easily (the inboard end did look "burned" and worn. The disconnect appeared to be coming out without much trouble. I was using a small chisel and wedging it between the disconnect housing and the oil pan housing and tapping it with a hammer. Long story short, the housing broke and left the "neck" portion stuck in the opening.

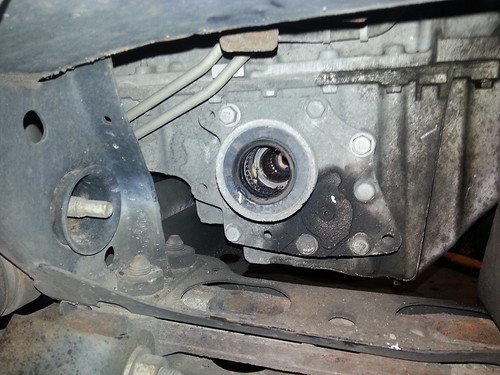

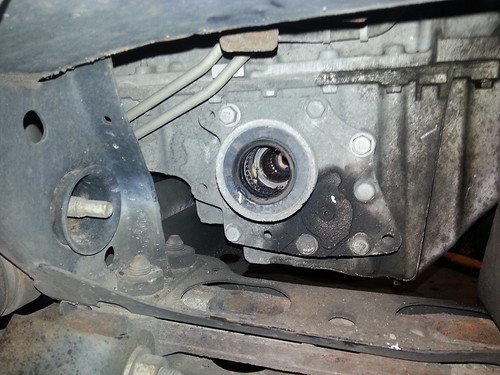

Axle pulled, and I can see some worn bits or dried up grease already.

Before

Before

After the disconnect is off. Looks even worse.

20141011_193731

20141011_193731

20141011_193749

20141011_193749

Broken housing backside. I wouldn't expect the grease to be collected in one spot. Any opinions on that?

20141011_193710

20141011_193710

20141011_193811

20141011_193811

I tried to tap some holes and put some bolts in to get a little something to pull on. There is basically no lip of the flange left to pull on. I tried two different pullers that I rented from Advance. No luck. Obviosly I tried using a screwdriver, crow bar, steel punch, etc. and hammering it away from the oil pan from below, but there's nothing to get a "bite" on.

1413126011284 333

1413126011284 333

Thought for sure I had it when I tapped two bolt holes and spanned it with some scrap parts. I then rented a slide hammer from advance and was able to get a lot of power in the slide, but this thing didn't budge. I've been using PB Blaster too all along.

20141012_130206

20141012_130206

So that is where I am with it. I had drive the vehicle in the meantime until I figure out a way to get this out. I pulled the front driveshaft and the passenger side axle is out (I need to replace that when I get the disconnect fixed). Am I correct in thinking that the center piece of the axle wont be spinning? If front wheels aren't engaged, shouldn't it be disconnected at the differential? I admit I may be in over my head here.

Axle pulled, and I can see some worn bits or dried up grease already.

Before

BeforeAfter the disconnect is off. Looks even worse.

20141011_193731

20141011_193731 20141011_193749

20141011_193749Broken housing backside. I wouldn't expect the grease to be collected in one spot. Any opinions on that?

20141011_193710

20141011_193710 20141011_193811

20141011_193811I tried to tap some holes and put some bolts in to get a little something to pull on. There is basically no lip of the flange left to pull on. I tried two different pullers that I rented from Advance. No luck. Obviosly I tried using a screwdriver, crow bar, steel punch, etc. and hammering it away from the oil pan from below, but there's nothing to get a "bite" on.

1413126011284 333

1413126011284 333Thought for sure I had it when I tapped two bolt holes and spanned it with some scrap parts. I then rented a slide hammer from advance and was able to get a lot of power in the slide, but this thing didn't budge. I've been using PB Blaster too all along.

20141012_130206

20141012_130206So that is where I am with it. I had drive the vehicle in the meantime until I figure out a way to get this out. I pulled the front driveshaft and the passenger side axle is out (I need to replace that when I get the disconnect fixed). Am I correct in thinking that the center piece of the axle wont be spinning? If front wheels aren't engaged, shouldn't it be disconnected at the differential? I admit I may be in over my head here.