I have googled and read forums and I am now stuck so here is my story.

So I recently got into liking the trailblazer I bought a 04 2wd ( it has issues of its own now) and a 02 4wd (bought nonrunning for $400) I just wanted it as a project car and worse case parts for the 04, anyways stuff happened and the 04 it has some transmission issues now and around the same time I got the 02 working by pulling the power seats and LGM fuses, it used to say "unknown driver" and it became my daily driver.

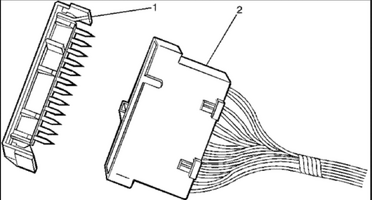

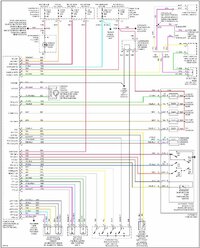

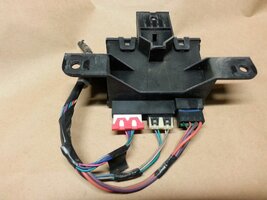

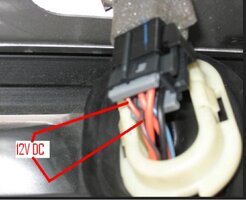

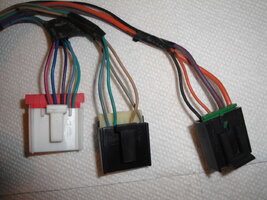

Now the fact I had to pull fuses to get it to run tells me there is a short making the PCM go crazy so I started with sp306 to see if something was going wrong there since it is associated with the LGM, uppon pulling up that flap the shit was melted so I cut the carpet from the fusebox to sp306, I dont care the carpet is under the seat and bad anyways, I found that whole bundle of wire and what I think is windhield fluid line melted together, so I went to work cutting out the old and splicing in new wire ( see pics below.. warning didn't color code since it wasn't even a foot of wire) while doing it sp306 fell off completely so I figured just splicing the light blue, blue white, tan, brown, and orange wires togeather would act as "sp306" and I believe I have everything wired up correctly but I still get no communication to or from the LGM and when putting the key in and turning it on the dash will say driver1 then after a few it says unknown driver and I lose all gauges but speed and rpm.

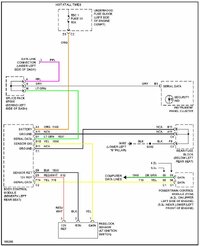

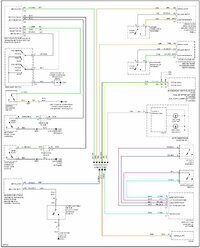

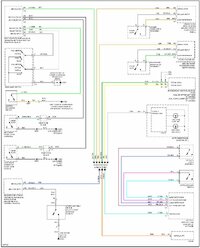

So after researching I find out the light blue wire from sp306 is to the LGM but if it can't communicate with it something is wrong with the wire or the module, now what I'm asking for is what the wiring path from the connector at the liftgate wiring harness to sp306? My problem is in that bundle there are three wires one of which is the LGM fuses and one of which is to the door chime fuse but the third one I can't find what it has continuity to since none of the fuses beeped at me (might be to the sunroof forgot I had it pulled since I have no sunroof) and since none of the light blue wires had continuity with the harness on the body side of the liftgate harness I am stuck, can anyone help?

So I recently got into liking the trailblazer I bought a 04 2wd ( it has issues of its own now) and a 02 4wd (bought nonrunning for $400) I just wanted it as a project car and worse case parts for the 04, anyways stuff happened and the 04 it has some transmission issues now and around the same time I got the 02 working by pulling the power seats and LGM fuses, it used to say "unknown driver" and it became my daily driver.

Now the fact I had to pull fuses to get it to run tells me there is a short making the PCM go crazy so I started with sp306 to see if something was going wrong there since it is associated with the LGM, uppon pulling up that flap the shit was melted so I cut the carpet from the fusebox to sp306, I dont care the carpet is under the seat and bad anyways, I found that whole bundle of wire and what I think is windhield fluid line melted together, so I went to work cutting out the old and splicing in new wire ( see pics below.. warning didn't color code since it wasn't even a foot of wire) while doing it sp306 fell off completely so I figured just splicing the light blue, blue white, tan, brown, and orange wires togeather would act as "sp306" and I believe I have everything wired up correctly but I still get no communication to or from the LGM and when putting the key in and turning it on the dash will say driver1 then after a few it says unknown driver and I lose all gauges but speed and rpm.

So after researching I find out the light blue wire from sp306 is to the LGM but if it can't communicate with it something is wrong with the wire or the module, now what I'm asking for is what the wiring path from the connector at the liftgate wiring harness to sp306? My problem is in that bundle there are three wires one of which is the LGM fuses and one of which is to the door chime fuse but the third one I can't find what it has continuity to since none of the fuses beeped at me (might be to the sunroof forgot I had it pulled since I have no sunroof) and since none of the light blue wires had continuity with the harness on the body side of the liftgate harness I am stuck, can anyone help?

Attachments

Last edited: