Hey guys I am new to your forum and I have an issue that is driving me nuts. I have a 2008 Chevy Suburban LT 4wd 5.3L Flex. Here is the breakdown of whats happening. When starting the truck it takes a long time to finally fire up, when it does it is hesitating and shuttering a bit. While driving it has lower than usual power on acceleration even though it will still run 70mph and the cruise still works telling me it probably isn't TPS related. I have changed the MAF, MAP, TPS, CKP, and CMP. CKP ran the snap-on solus for DTC's and only got the P0335. I cleaned the wheel speed sensors before doing this so that cured the abs issue I believe. I have great fuel pressure and the scan tool is showing no engine rpms as well. It shows CKP rpms and CMP rpms bot no active counts on the CKP? pulled the entire wiring harness off and inspected it thoroughly but found nothing wrong with it. I checked voltage at the cmp and got 5.03v at the reference and 5.03 at the signal. I changed the ecm and bcm and still get the same numbers. Anyone got any ideas I am at a loss here! Thanks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

08 Suburban ckp issue!!!!

- Thread starter king_strut

- Start date

Welcome to GMT Nation...

Your "Timing" for Posting is Perfect.

On High Mileage GM Trucks... Worn Crankshaft Main Bearings can sometimes create a "rotational off set" at varying RPM that can break up the Reluctor Wheel Readings being picked up by the CKP Hall Effect Sensor. Diagnosis of this kind is achieved using using either a Very Expensive PICO-Scope or an inexpensive Hantek 1008C Oscilloscope and Hantek Software on either a Windows Tablet or Laptop.

After Back-Probing the CKP Sensor Plug and observing the changing views on-screen, you'll see in the comparison images below that some Disrupted Square Wave Patterns collapse into Solid Vertical Lines as the RPM are increased after the Shifter is placed In Gear and the Brakes are pressed.

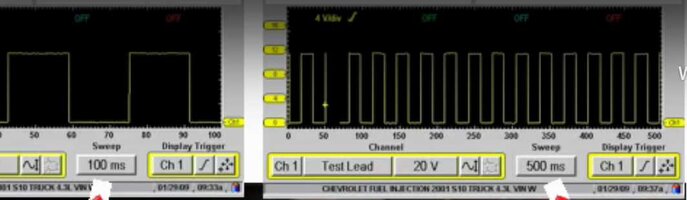

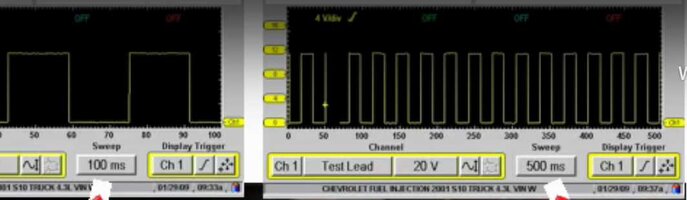

Here, you can see a Fairly Normal CKP Sensor Signal Square Wave Pattern at Idle:

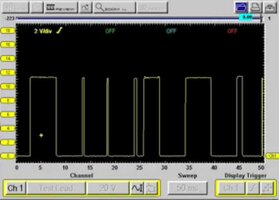

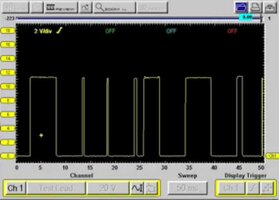

But, once the Brakes are Applied and the Engine RPM are Elevated for a Brake-Torque Test:

You can clearly see the "Vertical Lines" forming as the Hall Effect Signal Break Up happens just when the Crankshaft is being Torque Stressed out of its idling rotational orbit... just enough to cause the CKP Sensor Signal to Break Up and ruin the Ignition Spark-Plug Firing and EFI Timing information needed by the PCM. moment by moment. "Thin Shimming" the Body of the CKP Sensor can sometimes mitigate this problem by moving the Sensor just a little off of its normal seated position inside of the Engine Block:

Also, IIANM... GM Trucks with V8 Engines are supposed to have some Redundant Engine Running capability, as long as there is a working CPS allowing the PCM and IT to calculate Spark and EFI Timing well enough to keep the Engine Running, should the CKP Sensor goes sideways and avoid leaving the Truck Owner stranded on the side of the road. And THAT leads into a situation that recently occurred involving the Mistaken Installation of the Wrong CKP Sensor that presented with similar Misfire-Backfire and Poorly Running Engine issues.

Its recommended to make a Double Check on the 'Box Part #s vs. Parts In Hand'... Double Checking what is INSIDE of the Box versus What is Marked on the OUTSIDE of the Box right there at the Parts Counter each and every time. This cautionary approach can sidestep the loss of Time and Money after buying someone else's 'Old Part' or getting and installing one that does not match the requested component.. In this case... The Question Begs... Is there a Wrong CKP Sensor (24X? 58X?) Installed inside of your Engine Block?

Your "Timing" for Posting is Perfect.

On High Mileage GM Trucks... Worn Crankshaft Main Bearings can sometimes create a "rotational off set" at varying RPM that can break up the Reluctor Wheel Readings being picked up by the CKP Hall Effect Sensor. Diagnosis of this kind is achieved using using either a Very Expensive PICO-Scope or an inexpensive Hantek 1008C Oscilloscope and Hantek Software on either a Windows Tablet or Laptop.

After Back-Probing the CKP Sensor Plug and observing the changing views on-screen, you'll see in the comparison images below that some Disrupted Square Wave Patterns collapse into Solid Vertical Lines as the RPM are increased after the Shifter is placed In Gear and the Brakes are pressed.

Here, you can see a Fairly Normal CKP Sensor Signal Square Wave Pattern at Idle:

But, once the Brakes are Applied and the Engine RPM are Elevated for a Brake-Torque Test:

You can clearly see the "Vertical Lines" forming as the Hall Effect Signal Break Up happens just when the Crankshaft is being Torque Stressed out of its idling rotational orbit... just enough to cause the CKP Sensor Signal to Break Up and ruin the Ignition Spark-Plug Firing and EFI Timing information needed by the PCM. moment by moment. "Thin Shimming" the Body of the CKP Sensor can sometimes mitigate this problem by moving the Sensor just a little off of its normal seated position inside of the Engine Block:

Also, IIANM... GM Trucks with V8 Engines are supposed to have some Redundant Engine Running capability, as long as there is a working CPS allowing the PCM and IT to calculate Spark and EFI Timing well enough to keep the Engine Running, should the CKP Sensor goes sideways and avoid leaving the Truck Owner stranded on the side of the road. And THAT leads into a situation that recently occurred involving the Mistaken Installation of the Wrong CKP Sensor that presented with similar Misfire-Backfire and Poorly Running Engine issues.

Its recommended to make a Double Check on the 'Box Part #s vs. Parts In Hand'... Double Checking what is INSIDE of the Box versus What is Marked on the OUTSIDE of the Box right there at the Parts Counter each and every time. This cautionary approach can sidestep the loss of Time and Money after buying someone else's 'Old Part' or getting and installing one that does not match the requested component.. In this case... The Question Begs... Is there a Wrong CKP Sensor (24X? 58X?) Installed inside of your Engine Block?

Last edited:

I have tried two different ckps and still get the same issue. I get no pulse at all from the ckp. Just the 2.38v constant signal. reference is sending a constant 5.03v to it. low reference is 0. What would the symptoms of a bad reluctor wheel be in my case? I hope that isnt the issue and if it were wouldnt I get an intermittent signal? At least something?

Mooseman

Moderator

Yes... and if possible, check the Suspected OEM CKP Sensor for any signs of physical damage to the inner-dwelling cylinder portion showing any linear scrape marks or smears from the Reluctor Notches making accidental rotational contact.

If not canted off angle from any such impacts.... the original Spot Welds might have broken loose at Higher RPM and cause the Reluctor Wheel to just be riding along on the Base Circle OD of the outer journal as the Engine rotates; not providing the continuous Open and Closed action close enough and in syncopation with the Crankshaft motions well enough to have any affect at all on the CKP Hall Effect Sensor.

This is Part One of a Three Part Diagnostic covering the Loss of the CKP Signal on ALL LS Engines:

troubleshootmyvehicle.com

troubleshootmyvehicle.com

If not canted off angle from any such impacts.... the original Spot Welds might have broken loose at Higher RPM and cause the Reluctor Wheel to just be riding along on the Base Circle OD of the outer journal as the Engine rotates; not providing the continuous Open and Closed action close enough and in syncopation with the Crankshaft motions well enough to have any affect at all on the CKP Hall Effect Sensor.

This is Part One of a Three Part Diagnostic covering the Loss of the CKP Signal on ALL LS Engines:

CKP Sensor Test -No Spark No Start Tests (GM 4.8L, 5.3L, 6.0L)

How To Test The Crank Sensor: GM 4.8L, 5.3L, 6.0L. No Spark No Start troubleshooting. P0335, P0336 tests. Crank Sensor Test. GM 4.8L, 5.3L, 6.0L. Crank Sensor test with a Multimeter.

Last edited:

I have checked both the sensor which is perfectly fine and the reluctor wheel which is fine also. No wobble of flex at all. I get 4.7v with KOEO and 2.3v with it running on the signal wire for the ckp. I get the same thing on the cmp wires but the cmp signal jumps around from 2.2v-2,6v in that neighborhood. I get no pulse from the signal on the ckp at all just a steady 2.3v.

This must be you over on Paul Danner's Channel... (A Wise Move) ...if ANYONE can Dope this issue out and come up with a Working Solution... ScannerDanner Can (... or Cheryl):

www.scannerdanner.com

www.scannerdanner.com

UPDATE!!! 08 Suburban 5.3 ckp issue!!!!!!

UPDATE!!! 08 Suburban 5.3 ckp issue!!!!!!

Last edited:

m.mcmillen

Member

MRRSM: yes that is me also. I am hunting help everywhere I can. I did a short to ground test by disconnecting the sensor and pcm and connecting my multimeter to ground and touching the sensor wire on ohms and got nothing. I am lost here guys. nothing seems to be fixing my issue and everything I test is good to go other than the active counts/ pulse from the ckp!

You won't like this suggestion... but is there any possibility of having a problem with your High End Scanner? You could Test it out on another Vehicle if one is available and after Back Probing the CKP on THAT Engine... see if any Square Wave Signal appears on Screen. If nothing else, it would eliminate any Question regarding Possible Fault issues with the Scan Tool itself.

Looking around the Internet for the Best Possible Solution to solve your troubles is certainly nothing to be ashamed of ...as we all do this on a daily basis. We can all learn from each other, no matter where the information originates.

But... in THIS situation it would probably help us all to know what you have managed to find out from all these other resources so far, so that no additional unnecessary duplication of suggestions and efforts get mulled over that you have already received answers to from other places. Like this other one you've posted on:

But... in THIS situation it would probably help us all to know what you have managed to find out from all these other resources so far, so that no additional unnecessary duplication of suggestions and efforts get mulled over that you have already received answers to from other places. Like this other one you've posted on:

I have been told to check all sort of things and I try to update all of the forums I am on with the information I get and what I have done to get it. I have since tried two different scan tools and both give me the same information. I have changed out the ecm with two different ones one of which was a known good one of the same model and year with no change in results. I dont have a scope so that is not an option for me at the moment. I do however have access to a known good engine harness that i will be getting Monday and putting on to see if it is actually a wiring issue that I just haven't found. I am willing to throw all the hours at this thing I need too just to figure it out. I am a very enthusiastic mechanic and am always looking to learn something new everyday from anyone I can and as many as I can so thank you to all of you guys that have given your insight into my issue. I really appreciate all the help and I hope I get this resolved.

A side note I will be posting help to others as I read other posted issues I may have solutions for.

Oh and yes it is an Brand New OEM replacement ckp that I am using. It is the second one I have bought just to make sure I didnt get a defective one the first time. I did notice that when I hook up the positive terminal I get on heck of a spark each time. Possible short/ drain in the system somewhere would be my guess.

WOW.... Dumb Question of course, but..."Key Off - Ignition Off" when this occurred? And did this happen by 'attaching the Battery B+ Red Lead' ...or when the CKP Harness Connector is being hooked up AFTER the CKP is bolted down on the Engine Block? Just wondering if the Ignition Switch was not turning the Power completely OFF.

With the Key On... the GM Class 2 Network uses VPW (Variable Pulse Width) Modulation in the 0-7 Volts DC Range, so the Signal Wire should read around 5-7 Volts in the Active State if the PCM is Healthy.

With an Oscilloscope hooked up with a Low Amp Clamp around the CKP Harness... you would see a thin, fluctuating Square Wave PWM image line on the Screen visually rendering and measuring "Voltage over Time" at the PCM-BCM. The same applies for Any/All Modules connected to the Network... even when the Engine is NOT running.

This is also where @m.mcmillen 's suggestion in Post #8 comes in again for consideration with Checking the "Air Gap" between the Flat at the bottom of CKP Sensor Cylinder and one of the protruding Outer Notch sections of the Crankshaft Reluctor Wheel to measure fairly closely and ensure there is a MINIMUM of 0.030" Gap:

And here is where using the proper thickness of the gap-adjustable Metal Washers come into play to expand the distance to that "Goldilocks Position" of being 'Neither TOO Close Nor TOO Far Away' from the Reluctor Wheel.

Eric "O" from South Main Auto suggests that an EZ way to do this is to use a bit of Play Dough glommed onto the tip of the CKP Sensor (remove the CKP outer "O" Ring, too). Then after sticking The Thing into the CKP access port inside the Block with a Reluctor Notch aligned and pressing it in HARD, you'd carefully pull it out and measure this Gap with a Micrometer Caliper's Depth Gauge Feature as shown in the Video below:

NOTE:

Will Robinson's Auto has an Excellent YT Video on Diagnosing Class 2 Network issues at the BCM and Splice Pack(s) using an Oscilloscope, a Tech 2, a DMM and a Lighted Probe that nicely demonstrates the 5 Volt DC Ref Signals communication between the PCM, the BCM and all the Modules.

And jik it turns out that the Reluctor Wheel has been slipping from its proper position on the Crankshaft... Here is a Used 2008 Chevrolet Suburban 5.3l Crankshaft available on eBay:

With the Key On... the GM Class 2 Network uses VPW (Variable Pulse Width) Modulation in the 0-7 Volts DC Range, so the Signal Wire should read around 5-7 Volts in the Active State if the PCM is Healthy.

With an Oscilloscope hooked up with a Low Amp Clamp around the CKP Harness... you would see a thin, fluctuating Square Wave PWM image line on the Screen visually rendering and measuring "Voltage over Time" at the PCM-BCM. The same applies for Any/All Modules connected to the Network... even when the Engine is NOT running.

This is also where @m.mcmillen 's suggestion in Post #8 comes in again for consideration with Checking the "Air Gap" between the Flat at the bottom of CKP Sensor Cylinder and one of the protruding Outer Notch sections of the Crankshaft Reluctor Wheel to measure fairly closely and ensure there is a MINIMUM of 0.030" Gap:

And here is where using the proper thickness of the gap-adjustable Metal Washers come into play to expand the distance to that "Goldilocks Position" of being 'Neither TOO Close Nor TOO Far Away' from the Reluctor Wheel.

Eric "O" from South Main Auto suggests that an EZ way to do this is to use a bit of Play Dough glommed onto the tip of the CKP Sensor (remove the CKP outer "O" Ring, too). Then after sticking The Thing into the CKP access port inside the Block with a Reluctor Notch aligned and pressing it in HARD, you'd carefully pull it out and measure this Gap with a Micrometer Caliper's Depth Gauge Feature as shown in the Video below:

NOTE:

Will Robinson's Auto has an Excellent YT Video on Diagnosing Class 2 Network issues at the BCM and Splice Pack(s) using an Oscilloscope, a Tech 2, a DMM and a Lighted Probe that nicely demonstrates the 5 Volt DC Ref Signals communication between the PCM, the BCM and all the Modules.

And jik it turns out that the Reluctor Wheel has been slipping from its proper position on the Crankshaft... Here is a Used 2008 Chevrolet Suburban 5.3l Crankshaft available on eBay:

Electronics, Cars, Fashion, Collectibles & More | eBay

Buy & sell electronics, cars, clothes, collectibles & more on eBay, the world's online marketplace. Top brands, low prices & free shipping on many items.

rover.ebay.com

Attachments

Last edited: