There is nothing unusual about Stretched TTY Bolts having exceeded their Plastic Deformation Limits and Breaking off during their removal. You are dealing with an ALL Aluminum Engine with an Aluminum Engine Head that expands and contracts at THREE TIMES the rate of any Cast Iron Engine Block under conditions that would cause even the Strongest Studs made of 10.9 Hard Steel

to simply Snap Off within a matter of just a few Thermal Cycles!

I defy you to find any similar engine that is capable of running for 250,000 to 500,000 Miles

...even when poorly treated ...as well as this Atlas Engine has proven itself capable of achieving ...time and time again.

"POS"...? We Hardly Think So...!

Now ignoring all of that... I have a little experience with this latest task you face of Removing Broken Mains Caps Bolt Shanks out of the GM Atlas 4.2L LL8 Engine Blocks. The attached images are excerpted from an Article I've recently posted:

Pictorial Overview: https://www.flickr.com/photos/126111508@N07/albums/72157701032583401 Part 1 of 3 Parts: Abstract: This is a Repair Guide for using a Modified Technique vs. the Classic“The TIME-SERT Method” to more precisely install (14) M10 X 1.50 X 40MM Threaded Steel Cylinders inside...

gmtnation.com

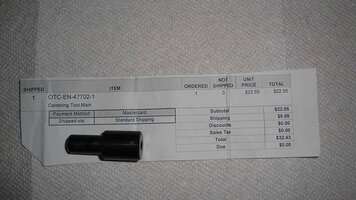

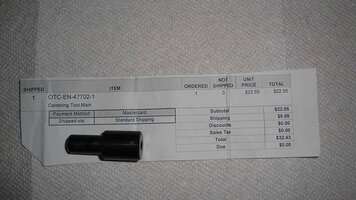

You should NOT need to go to the lengths covered therein for creating a Stronger Bottom End in your Motor using the TIME-SERT Method with M10X1.50X40mm Inserts... but the attached images might make this job a little bit easier for you. The inexpensive

OTC Drill Guide listed with the Purchase receipt Part Number will prevent the present dilemma going from Bad to Worse, should the Numerous Mains Caps Bolts Holes in the Aluminum Engine Block accidentally get damaged during these numerous but necessary extractions.

Some of them may come out easily... while others may not. Please note that the use I made of

Saran Wrap and the

Telescoping Neodymium and

Kitchen Magnets are NOT trivial matters. The need for controlling the surprisingly large amount of Broken Bolts Drill-Out Dross being created from dropping down inside of all the local vacant Bearing Lubrication Slots and other Openings is obvious.

If these protective measures gets overlooked, it will invite a LOT more unnecessary work and create a whole new set of issues to deal with AFTER the Engine is re-assembled, should any Metal Shavings migrate back into the spaces between the Crankshaft Journals and the Aluminum Silicate Bearing Halves. So in this case

... "An Ounce of Prevention ...REALLY IS ...Worth a Pound of CURE.":

Avoid using Compressed "Canned" Air to clear out the Blind Bolt Holes BEFORE all of the Engine Block Openings are covered in that Clear Plastic Cling Wrap. Do NOT Leave any Liquid Brake-Kleen or Oil Lubrication to Pool down inside those Blind Bolt Holes as Hydro-Locking these TTY Bolts before they can thread as far down as necessary will occur and give a False Reading. In all case like this, there is a risk that the Lower Mains Caps will come apart from their Block Halves as soon as the Engine is Started.

)

)

I got it ass-ackwards. Thought it was the 08 that he dropped in and wanted to swap the 04 crank in it. So it's the 04 that has a dead cylinder.

I got it ass-ackwards. Thought it was the 08 that he dropped in and wanted to swap the 04 crank in it. So it's the 04 that has a dead cylinder.