- Oct 14, 2014

- 872

The local stores here no longer loan out spring compressors (liability?) so it looks like I'll have to buy a set. I've narrowed it down to two styles...

http://www.amazon.ca/Powerbuilt-648627-Strut-Spring-Compressor/dp/B001OC5QJS/ref=sr_1_1?ie=UTF8&qid=1450199299&sr=8-1&keywords=strut+spring+compressor&tag=gmtnation-ca-20

^ That is the type they used to loan and I've used once before on a different vehicle. They worked well and I liked the safety pins.

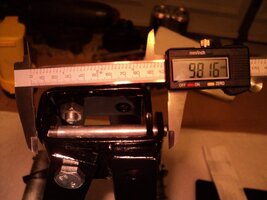

There's also this style I've found... same brand but listed as "Heavy Duty". They don't look any more robust to me but if they actually are I would think they would be the ones to buy. I've seen some early photos of a similar set being used by @The_Roadie and they looked like they were starting to bend (attached photo)...

http://www.amazon.ca/Powerbuilt-940562-Heavy-Spring-Compressor/dp/B00GJJZ0WE/ref=sr_1_5?ie=UTF8&qid=1450199299&sr=8-5&keywords=strut+spring+compressor&tag=gmtnation-ca-20

Anyone here have experience with either set on this platform? Obviously the second set got the job done so I at least know they would work... just looking for the safer of the two.

http://www.amazon.ca/Powerbuilt-648627-Strut-Spring-Compressor/dp/B001OC5QJS/ref=sr_1_1?ie=UTF8&qid=1450199299&sr=8-1&keywords=strut+spring+compressor&tag=gmtnation-ca-20

^ That is the type they used to loan and I've used once before on a different vehicle. They worked well and I liked the safety pins.

There's also this style I've found... same brand but listed as "Heavy Duty". They don't look any more robust to me but if they actually are I would think they would be the ones to buy. I've seen some early photos of a similar set being used by @The_Roadie and they looked like they were starting to bend (attached photo)...

http://www.amazon.ca/Powerbuilt-940562-Heavy-Spring-Compressor/dp/B00GJJZ0WE/ref=sr_1_5?ie=UTF8&qid=1450199299&sr=8-5&keywords=strut+spring+compressor&tag=gmtnation-ca-20

Anyone here have experience with either set on this platform? Obviously the second set got the job done so I at least know they would work... just looking for the safer of the two.