she's built and fired....sounds good so far! I was expecting more noise out of the forged pistons. Sounds pretty good so far.

What a tight squeeze to fit that 4" intake and throttle body. That thing is huge. Took remaking the top supercharger mount and some real careful positioning to get the hood to close.

Here is the list...I'm sure I'm missing stuff.

built motor with k1 billet rods, forged venolia custom pistons 8.5:1, cylinders honed, new crank and oil pump, shimmed oil pump

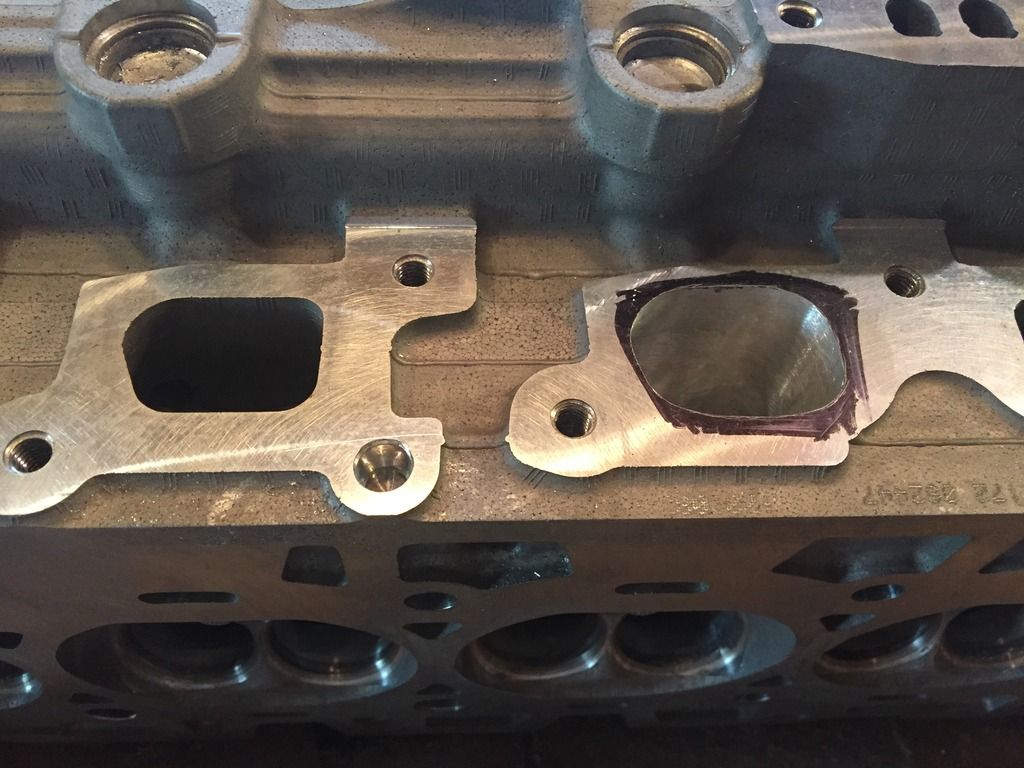

ported a new head and header flange to match exhaust-all this porting took forever...don't think I'll ever do this again! Making the custom gaskets took longer than I'll ever admit.

ported blower

bigger crank pulley to target 15 or 16 psi boost, custom crank pulley hub I made to use LFP pulley.

like this

4" throttle body and new 4" inlet to supercharger, custom flanges made

reworked and opened up header collector diameter

added resonator to quiet it down a bit and reworked exhaust

converted to 2wd, rebuilt tranny with beefed up components and a bunch of 4l65 upgrades

ebay radiator adapted to fit in stock location...its a perfect fit using the stock mounts and my derale fan. quite happy with how this turned out. It struggled to pull the temps down with the factory radiator.

ebay mopar radiator - trailblazer size

shortened a factory aluminum driveshaft to work with the SS rear

I've attached a bunch of photos.