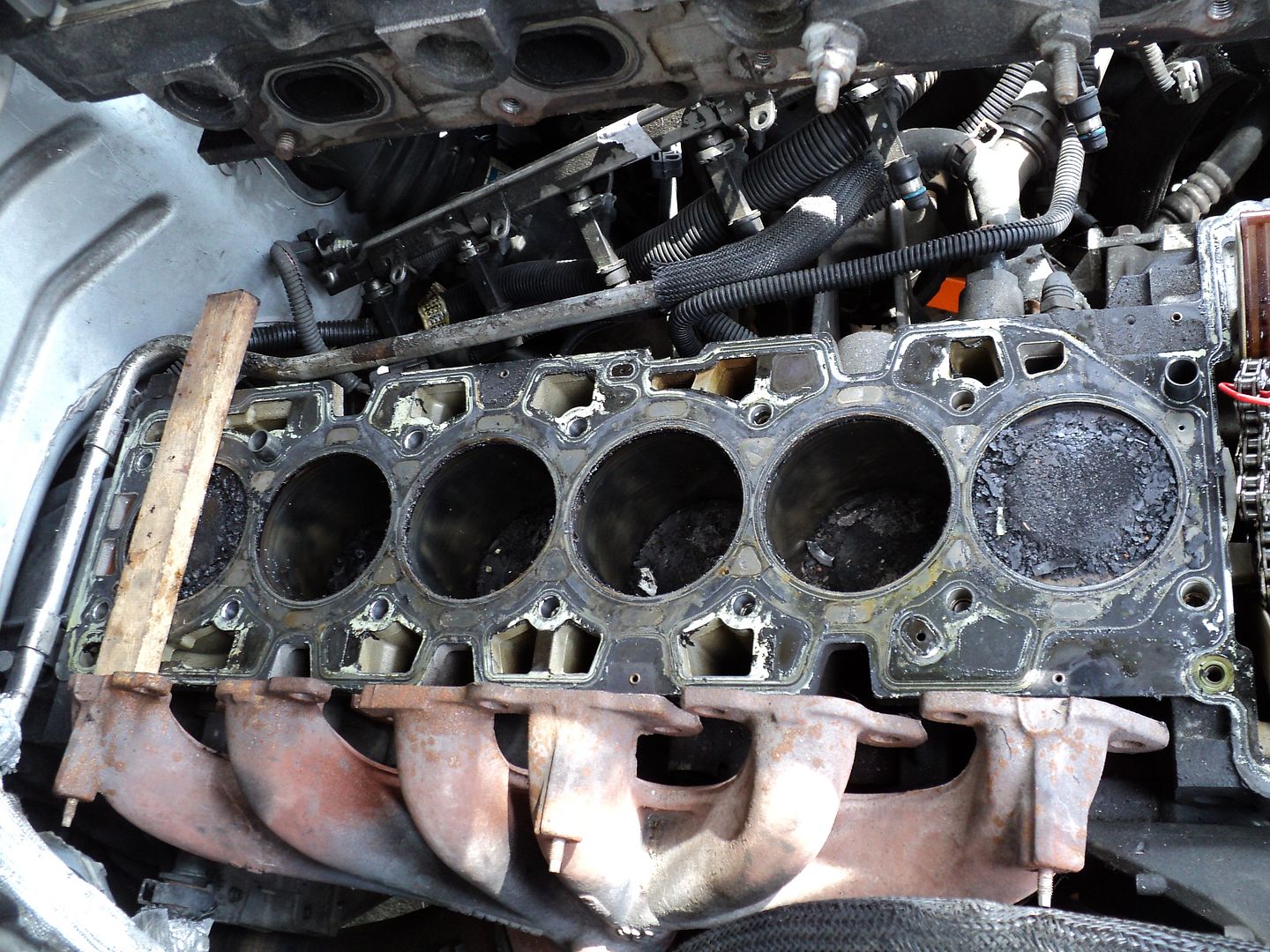

As I mentioned in a recent post in my build thread my 97x has been suffering from hard starts when warm, a pretty rough idle and a minor but existent lack of power. One of the intake valves on the #6 is bad, which is causing low compression. I had my mechanic check compression, and 6 was pretty low which has lead us to conclude bad or worn valves. It's okay enough that I can daily drive it still, but I'm getting so sick of the ticking.

There's several threads on this subject but I figure it's worth a new one since I've yet to see one on the 9-7x.

So, for starters he's a video of the 9-7x idling like a diesel.

Anyways. I found a 2004 head used with 90k miles for $100. I'm going to clean it up and flatout reinstall. Due to money for one, and secondly to the fact this is a daily driver, It's just a gonna be straight up head swap. Only thing I'm buying is the new head, head bolts and head set. That's it.

This thread will take some time, and it'll be a work in progress. I'll make sure to take plenty of pictures, because it's rare that I see them.

There's several threads on this subject but I figure it's worth a new one since I've yet to see one on the 9-7x.

So, for starters he's a video of the 9-7x idling like a diesel.

Anyways. I found a 2004 head used with 90k miles for $100. I'm going to clean it up and flatout reinstall. Due to money for one, and secondly to the fact this is a daily driver, It's just a gonna be straight up head swap. Only thing I'm buying is the new head, head bolts and head set. That's it.

This thread will take some time, and it'll be a work in progress. I'll make sure to take plenty of pictures, because it's rare that I see them.

Its all good

Its all good  . Gonna drive it into the ground?... maybe

. Gonna drive it into the ground?... maybe