@budwich ...That is an excellent observation… the Pintle/Filter unit is referred to as an “Orifice Filter Tube” in the automotive world as it sits inside of a hidden High Pressure Line along the upper inner fender well of the Trailblazer vehicles… and in other models is mounted at the Compressor Coils take-off pipe down by the front of the Radiator.

It is a difficult thing to access because it remains stuffed deep inside of a bolted up and sealed flange and requires a pair of long Needle Nose Pliers or a sturdy, long Hemostat to reach down inside and grab the thin rectangular plastic end of the unit and pull it out. It will appear to look like a toilet inside of a turn-of-the-century abandoned Bordello… and it will not respond well enough to cleaning. So replacing it with a brand new OEM Quality Orifice Tube will be necessary. This is the kind of Crap that when flushed off of the screens of the Orifice Tube will show the destruction of the AC Compressor inside:

Of course, the AC system will need to be evacuated to do this work and the entire system High and Low Pressure lines will need to be blown clean with a special AC Line Flush that is available at Autozone. Never flush the AC system with the AC Compressor installed… remove the Hi-Lo line manifold from it first and capture whatever blows through that two lines into a bucket. Avoid breathing the extremely vaporous stuff.

After installing a Brand New Orifice Tube… Replace the Accumulator with a Brand New one and do not remove the pre-sale protection plugs from it until you are ready to lubricate new Green “O” Rings with PAG 150 (Poly-Alkyl-Glycol) and tighten the fittings down carefully enough not to over torque them. They are Aluminum and very delicate… it is best to remember that its the Green “O” Rings that do the sealing… NOT the strength of your arm when putting any of this AC Hardware together.

The Rule of thumb is to first… quickly pour in 2 Ounces of PAG Oil into the Accumulator… 2 Ounces into the Compressor if being replaced with a Brand New OEM unit...and 2 Ounces of PAG Oil into the Condenser Coil opening at the top before sealing up all the lines and fasteners. This all must be done fairly quickly as the PAG Oil will soak up moisture right out of the the air and within 20 minutes after being “uncorked” the 6-8 Oz. Bottle of this stuff will become useless and saturated with too much water. So ‘Keep it Kapped’ and note that there is an Ounce Measurement Scale listed as you pour the stuff out marked clearly for the ease of use clearly visible right on the edges of the PAG container.

When all of the components are installed… use a Harbor Freight 2.5 CFM (Cubic Feet per Minute) or better Vacuum Pump and use the BEST Vacuum Oil you can buy...to evacuate the system for about an hour to remove any Air, Moisture and/or Non-Condensible Gases and bring the vacuum down as close to 25 Microns as read on the indication scale of your AC Manifold Gauge Set as possible in order to make everything inside a Bone Dry Vacuum like Deep Outer Space. Then the system can be re-charged with R-134A… using a Gram Scale to weigh in the charge as per the Owner’s Shop manual.

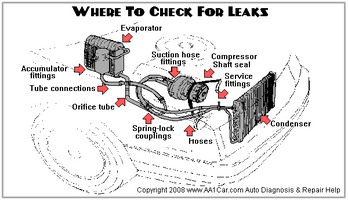

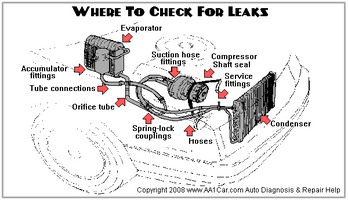

I have penned a “How To Repair The AC System” under the Articles Section for more specific details on how to do this job. In order to search and find AC Refrigerant leaks… You can purchase an inexpensive Digital Leak Detector tha is worth its weight in Platinum for making this job a lot easier to run down the leaks. This chart will show you where to use the device: